Multi-line cutting machine

A technology of multi-wire cutting machine and cutting area, which is applied in fine working devices, stone processing equipment, manufacturing tools, etc. It can solve the problems of poor heat dissipation, inconvenient maintenance of pipelines and components, and occupying space, etc., and achieves a compact structure , good control, convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

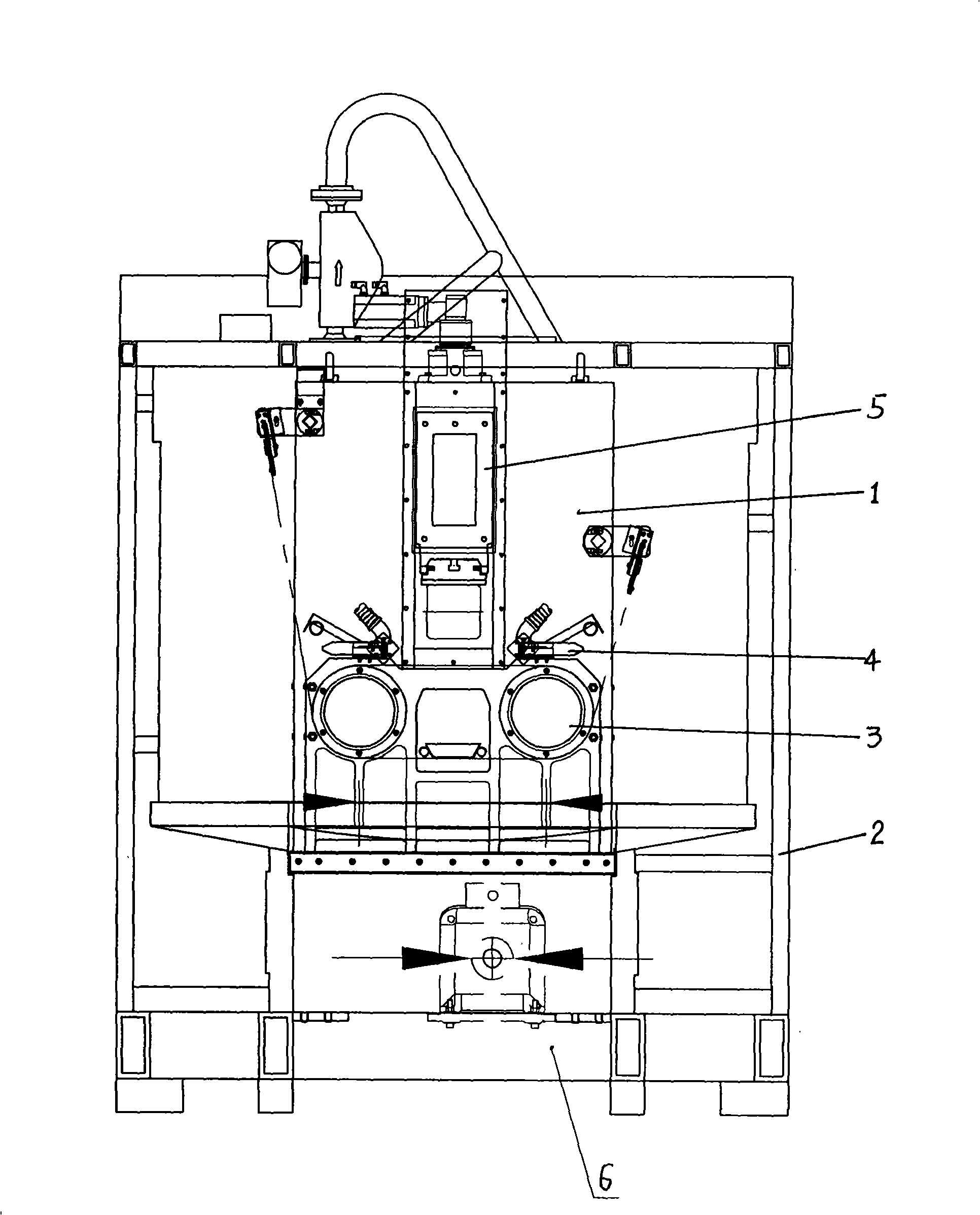

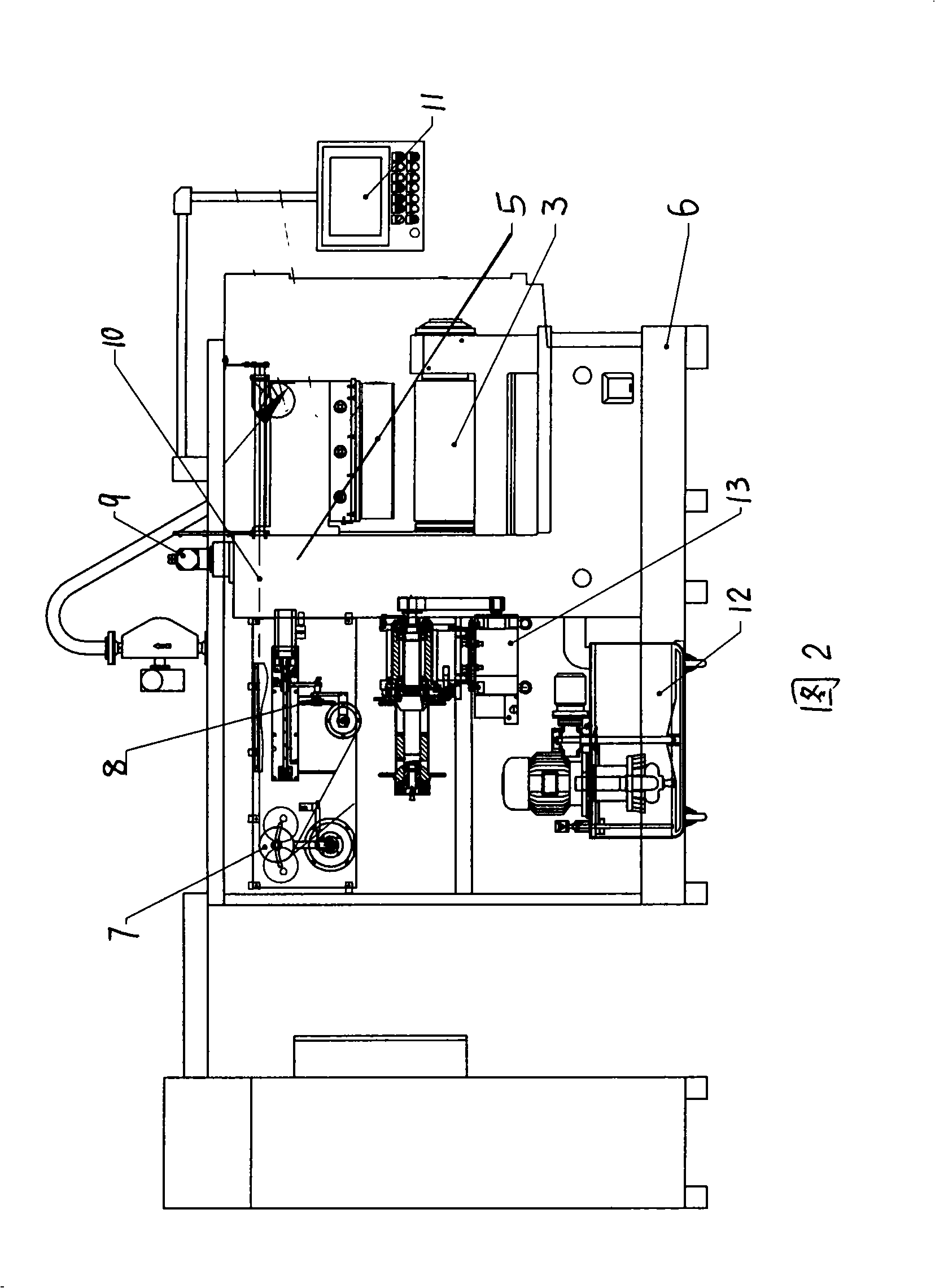

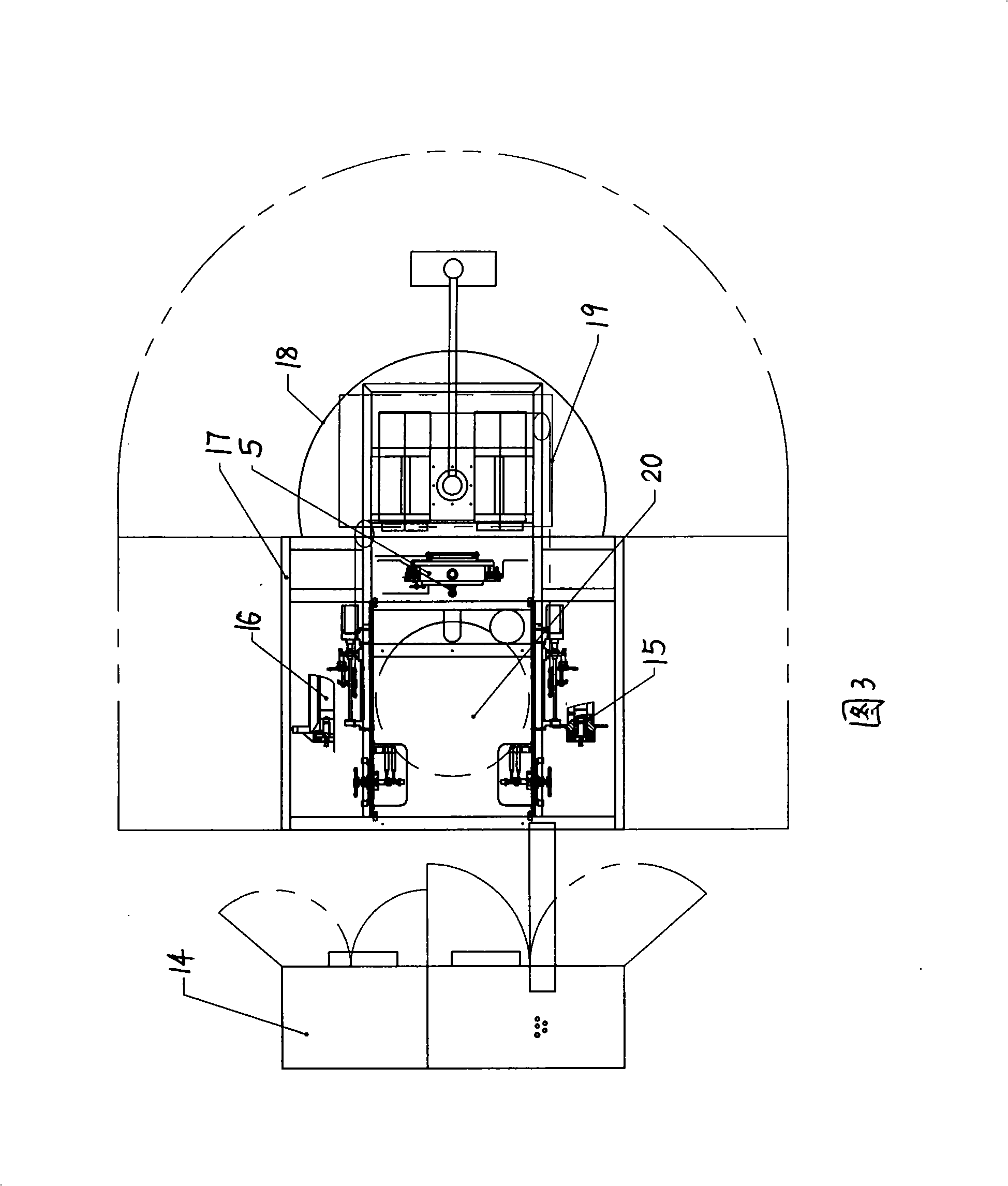

[0024] Multi-wire cutting machine, the body 2 is the base 6 and the column are integrated, the area in front of the column on the front of the machine tool is the cutting area, the frame 17 is fixed behind the column 1, the middle frame is the water-air slurry power management area, and the two sides of the water-air slurry power management area Inside the frame is the wire management area, and an electrical cabinet is installed outside the body to connect with the terminals of the water-air slurry electrical management area. The wire management area includes two wire guide wheels 3, on which the cutting wire net is distributed, and two left and right line In the management area, the steel wire of the cutting wire mesh is connected to the reels in the left and right two wire management areas. In the cutting area, the crystal rods and fixtures to be cut are installed on the feeding device of the column above the wire mesh, and the crystal rods are in contact with the wires for cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com