Preparation method of carbon nano tube/carbon fiber multi-dimension mixing composite material

A composite material and carbon nanotube technology, which is used in the preparation of composite materials and the preparation of carbon nanotube/carbon fiber multi-scale hybrid composite materials, can solve the problems of low viscosity, increased viscosity of resin system, and difficult to uniformly disperse, etc. The effect of improved impact resistance, improved interlaminar shear strength, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

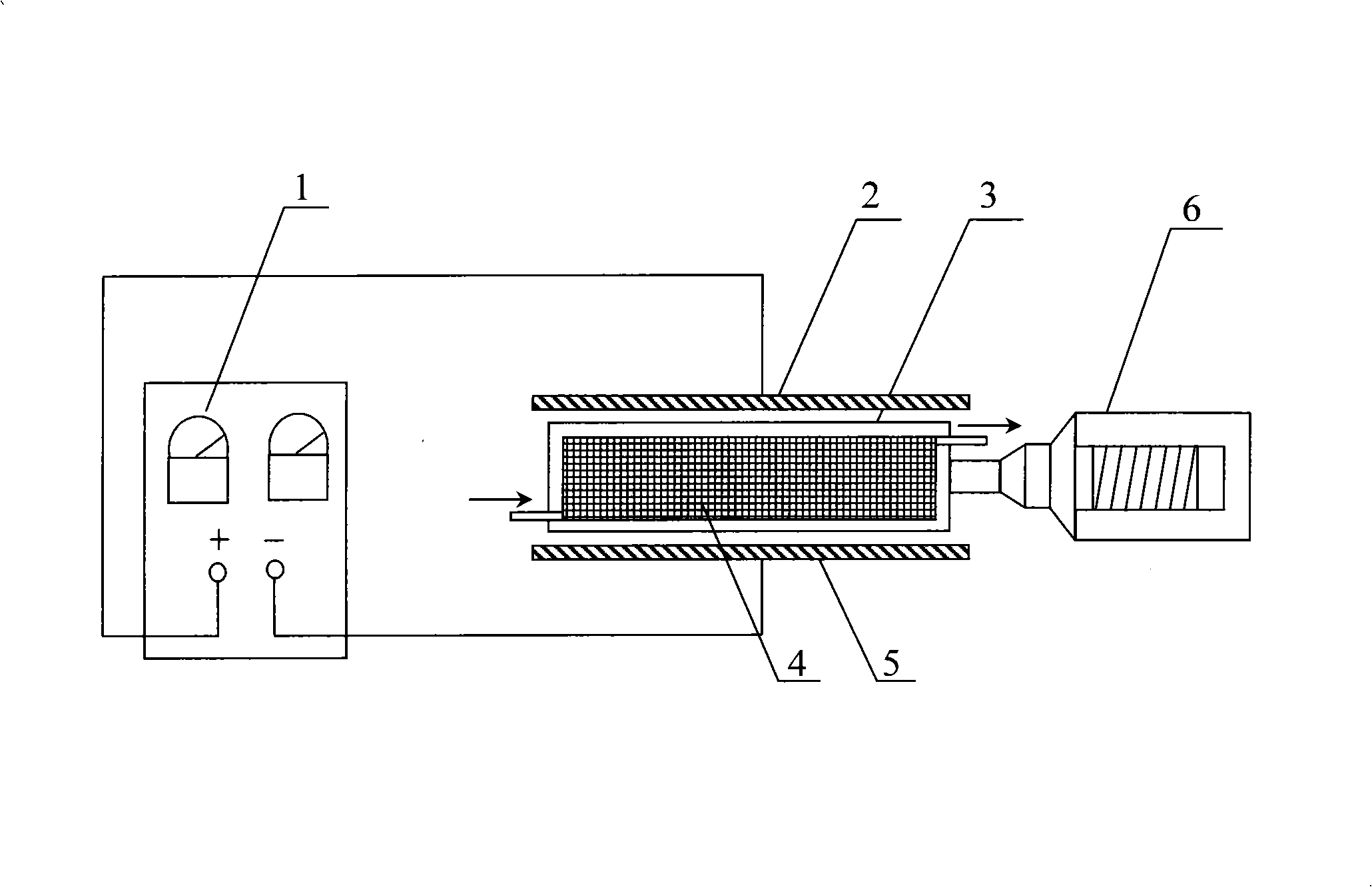

[0021] Preparation method of the present invention:

[0022] 1. Put the nanocomposite fiber preform into the pre-prepared mold.

[0023] 2. Put the mold in the ultrasonic field and electric field.

[0024] 3. Carry out mold filling and curing according to the LCM process, that is, multi-scale hybrid composite materials.

specific Embodiment approach 1

[0025] One specific embodiment: (1) put the nanocomposite fiber preform into the RTM mold; (2) put the mold into the electric field and the ultrasonic field, the DC voltage is 100V, the ultrasonic power is 100W, and the ultrasonic frequency is 45KHz; (3) ) Inject the stoichiometric epoxy / anhydride system into the mold with vacuum assistance; (4) After filling the mold, cure according to the curing system 130°C / 2h+150°C / 2h+180°C / 1h+200°C / 3h (5) Naturally cool to room temperature after the curing is completed, and the carbon nanotube / carbon fiber multi-scale hybrid composite material can be obtained after demoulding.

[0026] The interlaminar shear strength of the prepared carbon nanotube / carbon fiber multi-scale hybrid composite is increased by 80%, the impact resistance is increased by 20%, and the electrical conductivity in the direction of the electric field is also increased by three orders of magnitude.

specific Embodiment approach 2

[0027] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: after the mold filling is completed, continue to process in the ultrasonic field and electric field for 0.5h. Other steps and parameters are the same as those in Embodiment 1. The interlaminar shear strength of the prepared carbon nanotube / carbon fiber multi-scale hybrid composite material is increased by 87%, and the impact resistance performance is increased by 22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com