Sliding component and swirl motor compressor using the same

A technology of electric compressors, sliding components, applied in the direction of rotary piston machinery, engine components, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

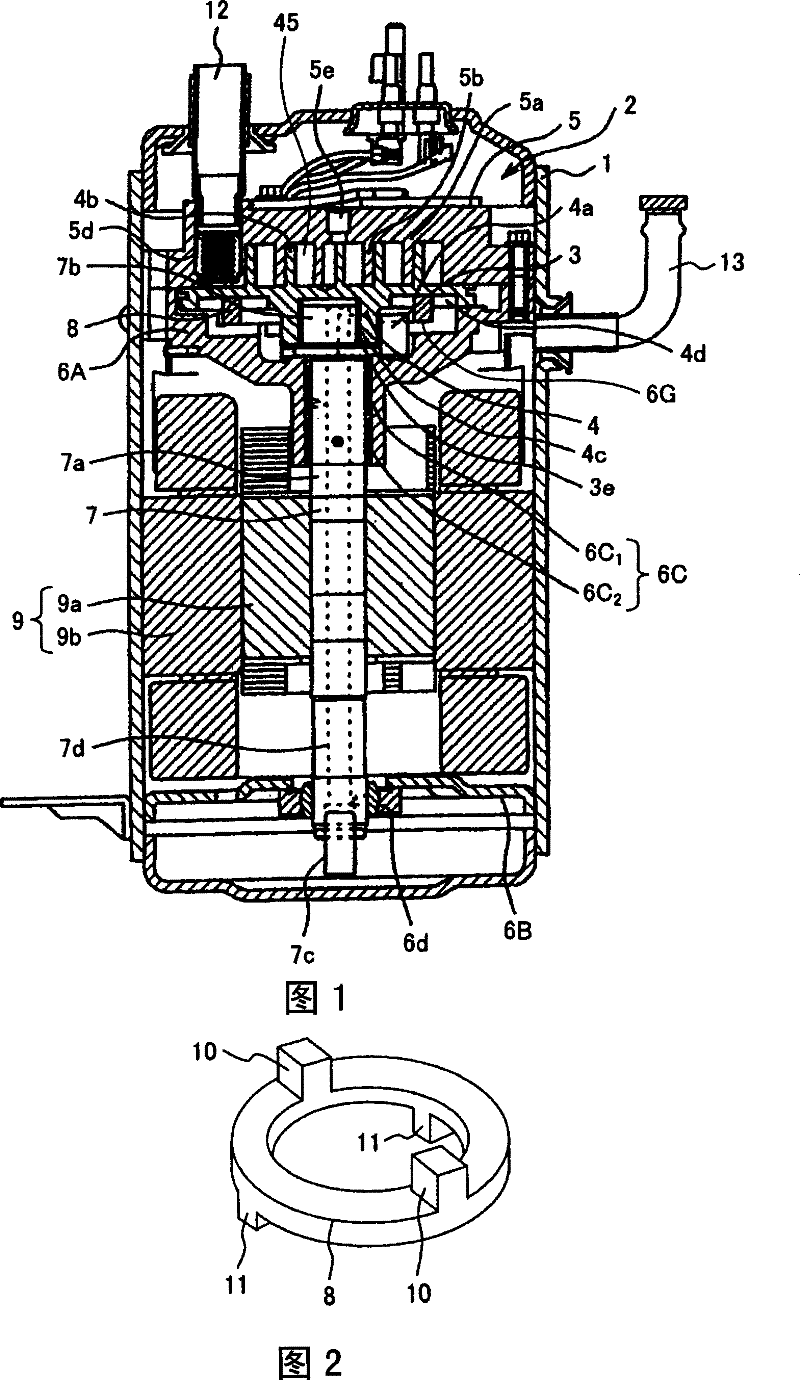

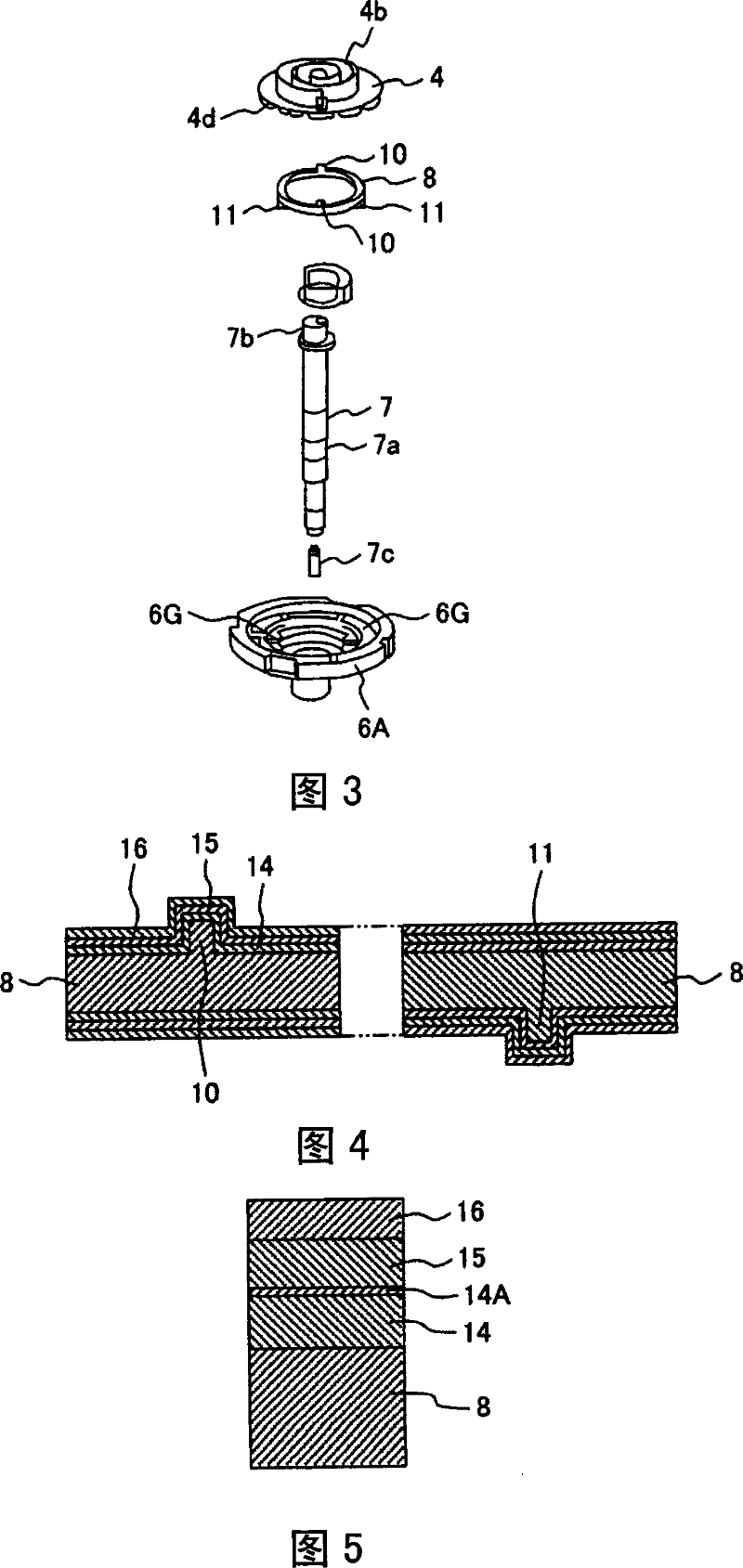

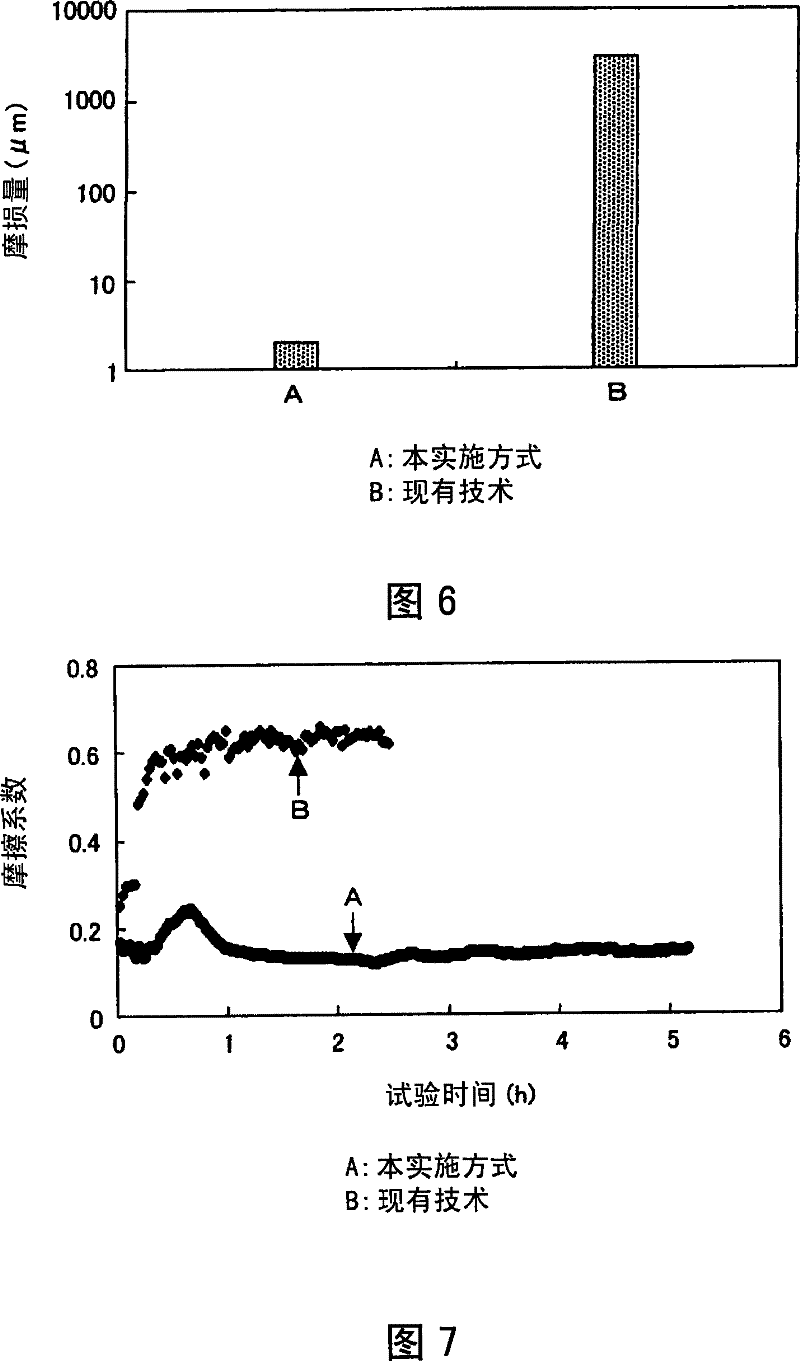

[0029] Hereinafter, an embodiment of the sliding member of the present invention will be described regarding a case where it is applied to an Oldham ring of a scroll electric compressor shown in FIGS. 1 to 5 .

[0030] The scroll electric compressor is a closed container 1 that stores lubricating oil at the bottom, a compression equipment part 2 that is installed in the closed container 1 and compresses chlorine-free alternative refrigerants or natural refrigerants, and rotates to drive the compressor. The rotary shaft 7 of the equipment unit 2 and the motor 9 for driving the rotary shaft 7 are the main components, and are vertical scroll electric compressors arranged in the vertical direction.

[0031] As an alternative refrigerant that does not contain chlorine, any one of R410a, carbon dioxide, and propane is used.

[0032] The compressor unit 2 is provided with a fixed turbine 5 standing downward on a fixed base plate 5a to form a scroll-shaped drum 5b, and a rotary turbin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com