Pipeline weld joint automatized ultrasound flaw detection device

An ultrasonic flaw detection and pipeline technology, which is applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. Positioning and other issues to achieve the effect of reducing environmental radiation pollution, reducing labor intensity, and good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

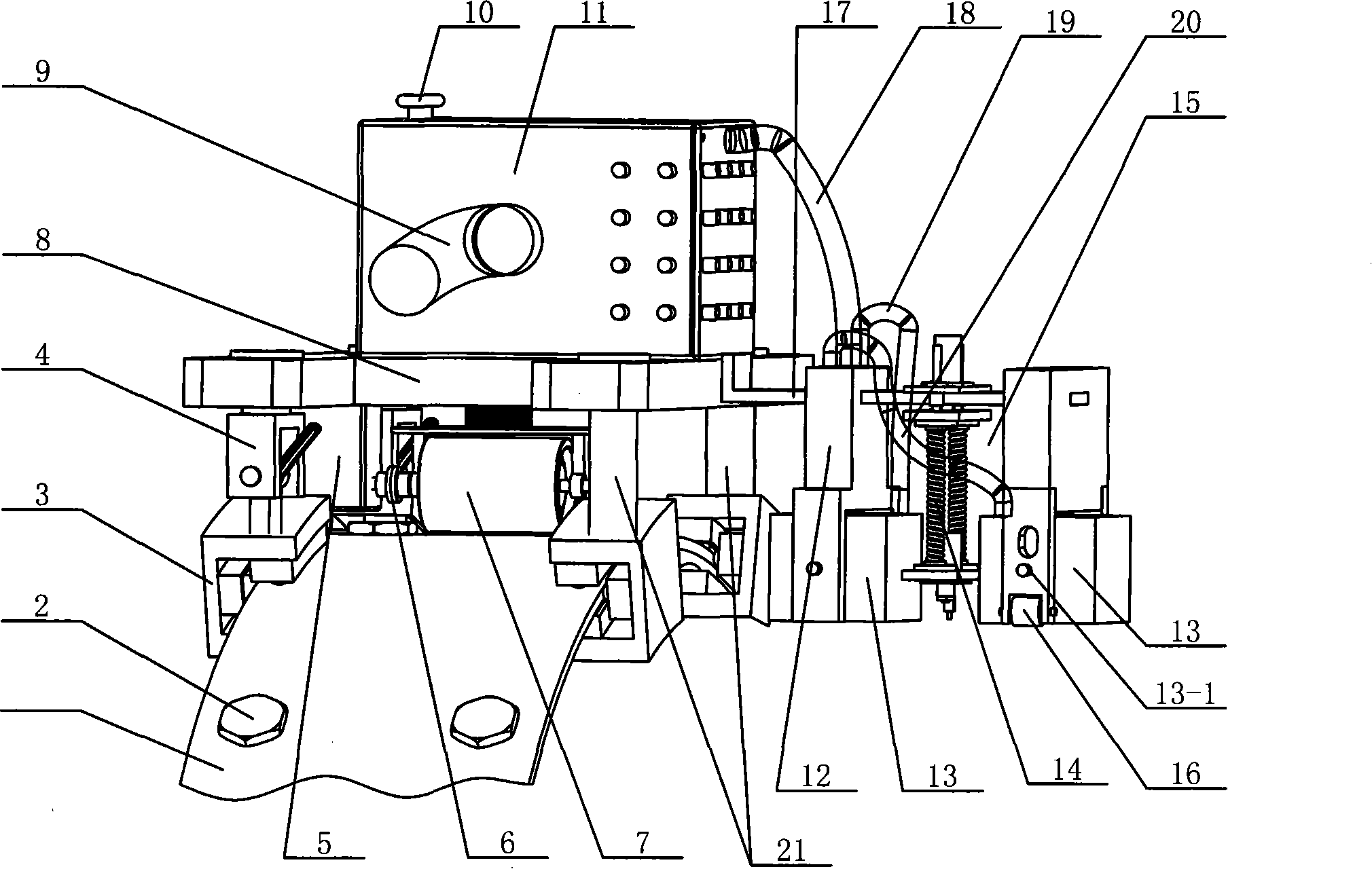

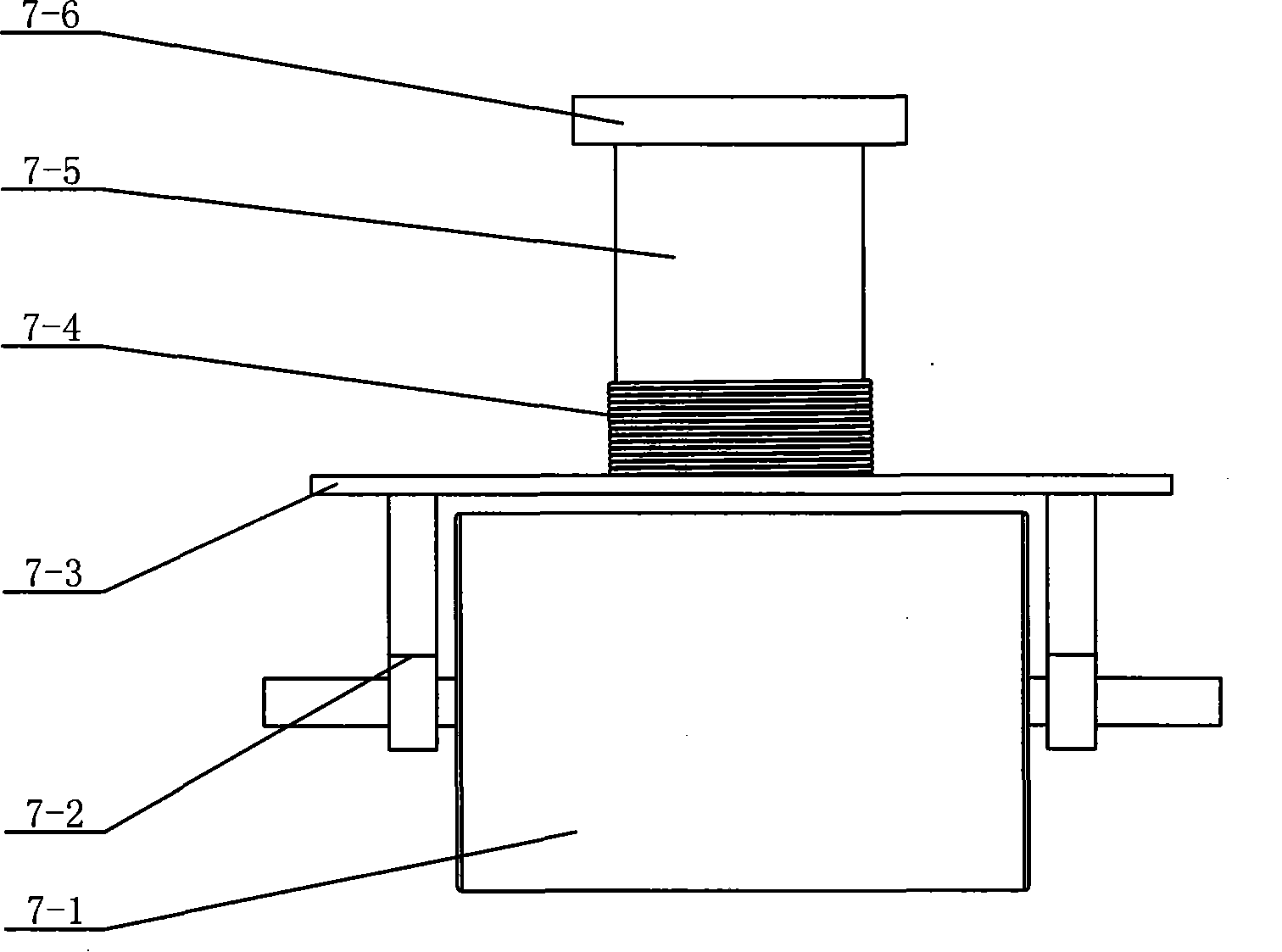

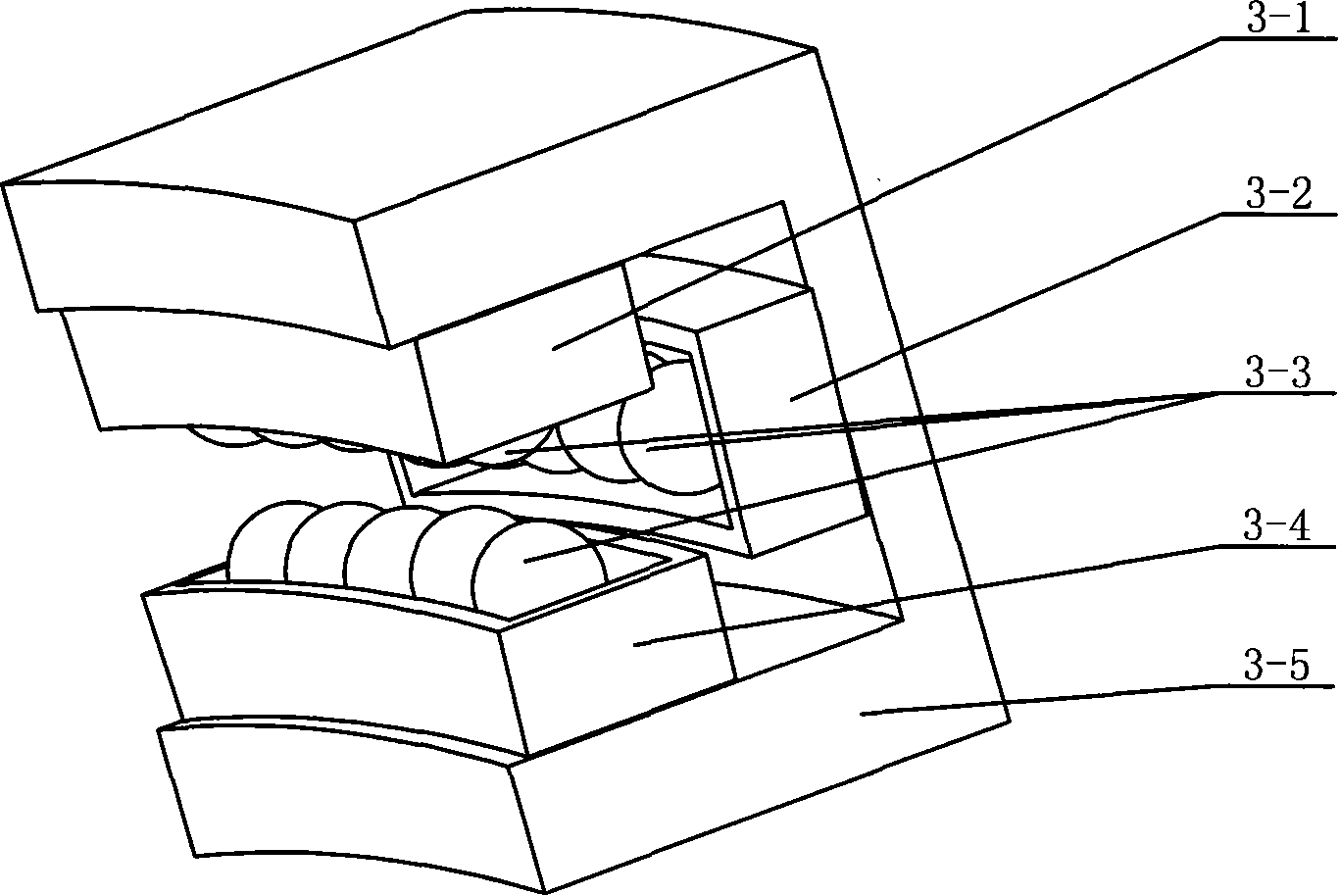

[0022] The present invention will be described in more detail below in conjunction with the accompanying drawings:

[0023] combine figure 1 , This embodiment is composed of the elastic track assembly part, the carrier trolley part, the probe scanning assembly part and the marking mechanism part; the carrier trolley is installed on the elastic track assembly, and the probe scanning assembly is fixed on the carrier trolley through the elastic plate , the marking mechanism is fixed on the elastic plate. The invention is externally connected with an ultrasonic flaw detector and an electromechanical control box. Before flaw detection, the surface of the girth weld of the pipeline and its vicinity should be derusted, polished and cooled, and a reference line should be drawn at the 12 o'clock position of the girth weld of the pipeline to supply the equipment to the equipment. The track is accurately positioned, and then the elastic track is fixed at a certain distance from the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com