Ion blower fan intelligentized control system

An ion fan and control system technology, applied in the field of static electricity, can solve the problems that cannot continuously and truly reflect the change of ion fan performance, cannot meet the requirements of centralized monitoring and automatic operation, and cannot meet the needs of large-scale industrialized production, so as to achieve the realization of centralized automation Monitoring function and/or remote control function, easy to popularize and promote, easy to directly refer to the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

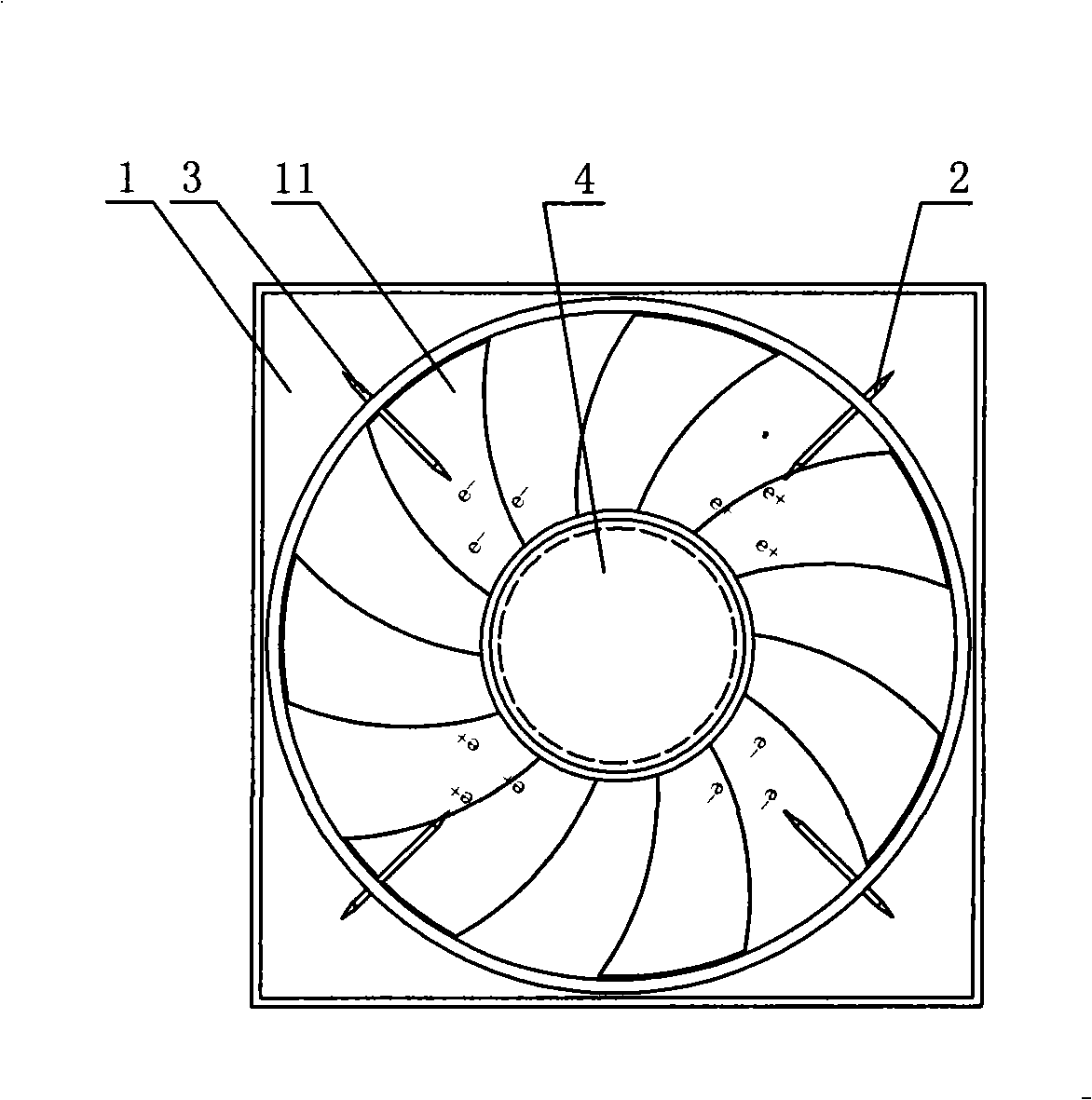

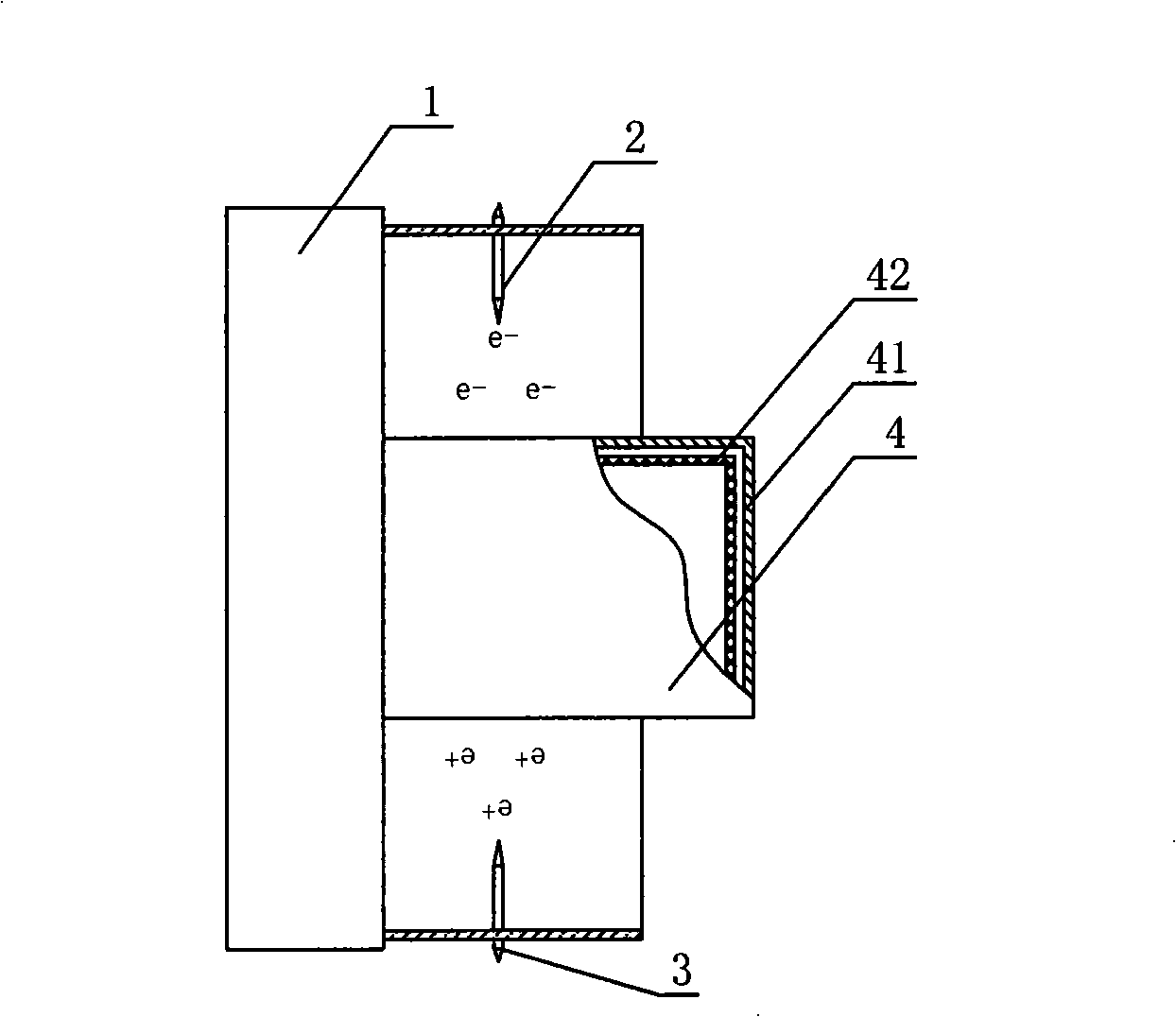

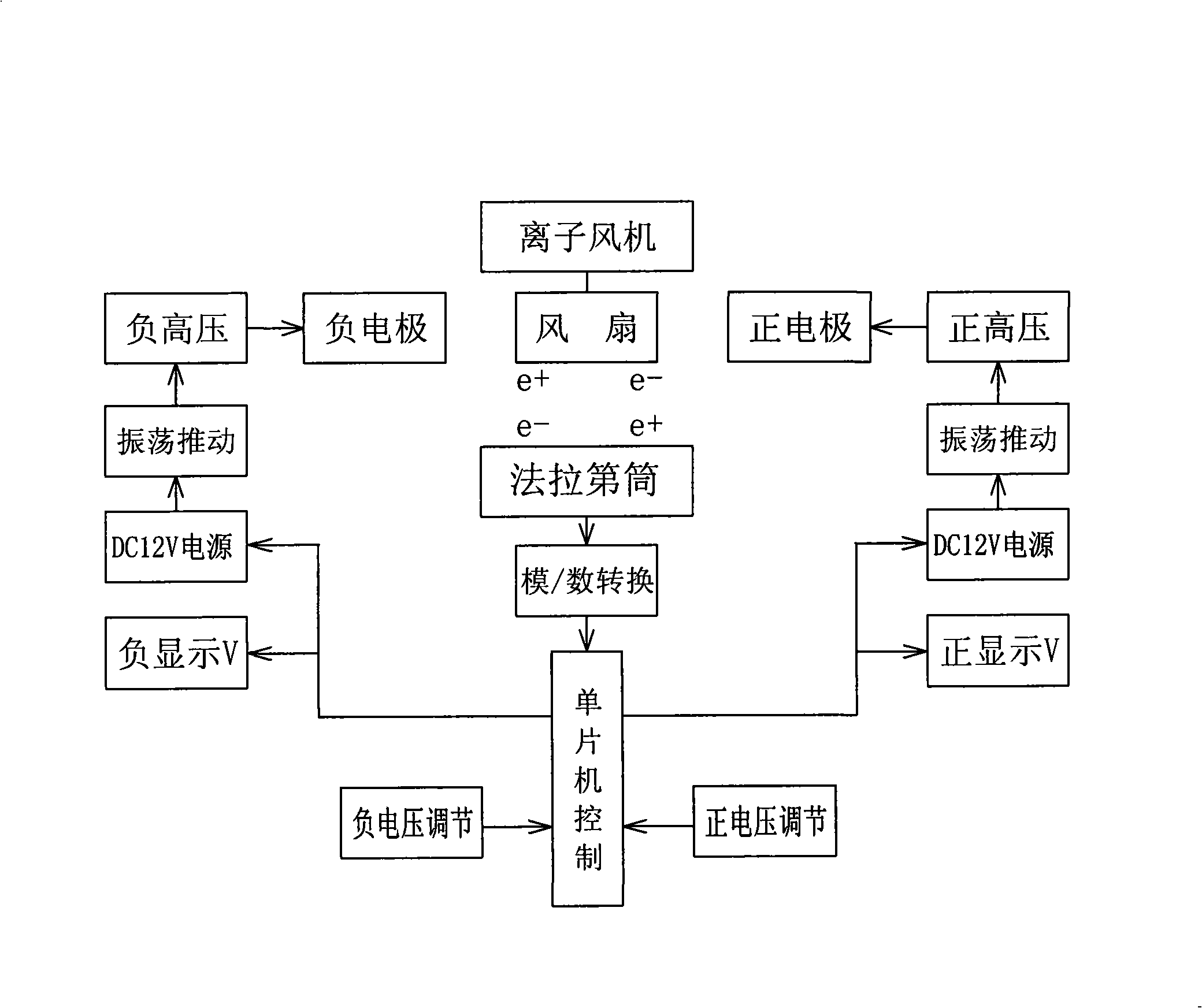

[0042] exist figure 1 with figure 2 Among them, the single ion fan in the present invention includes the positive and negative high voltage electrodes 2,3 of the axial flow fan 11, the positive and negative high voltage generating unit (not shown in the figure) and the high voltage discharge device, and its positive and negative high voltage generation The output terminals of the unit are respectively connected to the positive and negative high-voltage electrodes of the high-voltage discharge device, and a Faraday charge detection device 4 is installed in the middle of the air outlet of the axial flow fan.

[0043] The output end of the Faraday charge detection device is correspondingly connected with the I / O port of the single-chip microcomputer control unit.

[0044] The Faraday charge detection device is a Faraday Cage or a Faraday Cup.

[0045] Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com