Production method of flavor panax ginseng

A technology of ginseng and flavor, which is applied in the field of production of flavored ginseng, and can solve problems such as harm and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

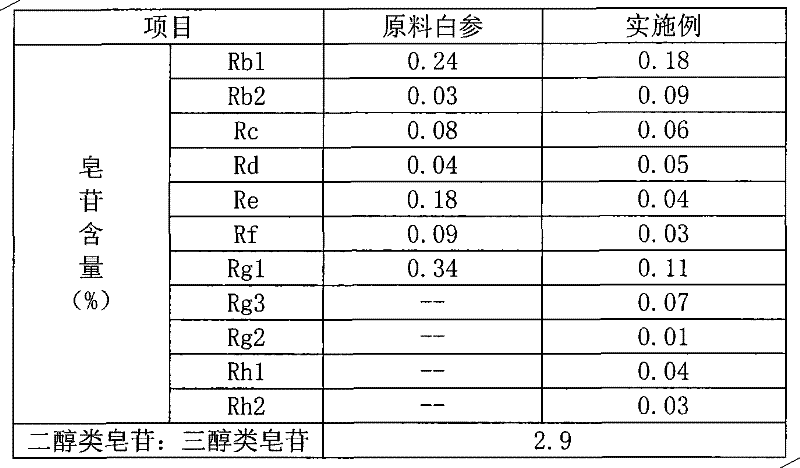

[0007] Example 1: Take 0.5 kg of fresh whole ginseng, directly dry it, and send it to test for various ginsenosides; take another 5.0 kg of fresh whole ginseng, add 0.5 times the amount of 0.15% citric acid solution and soak for 65 minutes, then add The ginseng body was taken out of the pressure vessel with a vacuum degree of 0.06 MPa under reduced pressure for 25 minutes, and the ginseng body was heated at 65° C. and pressurized by 0.1 MPa for 35 minutes. The ginseng body was dried with hot air to obtain 1.2 kg of ginseng with a water content of 5%. Submitted for inspection and tested various ginsenosides, and the content results are as follows:

[0008]

Embodiment 2

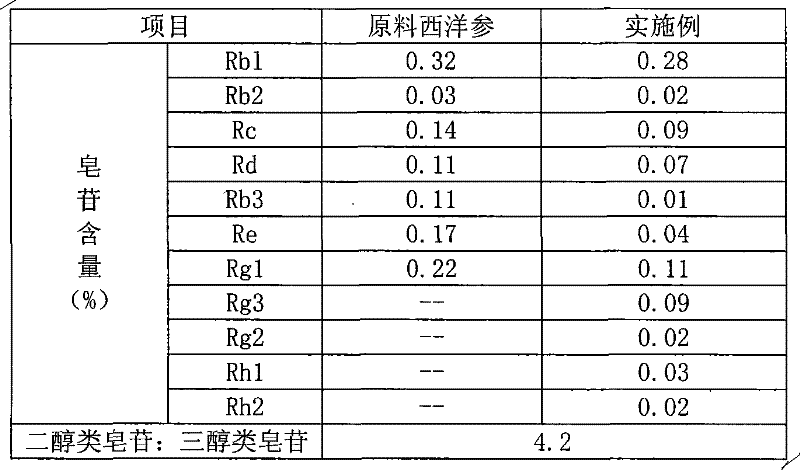

[0009] Example 2: Take 0.5kg of fresh whole American ginseng, directly dry it, and send it for testing to contain various ginsenosides; take another 5.0kg of fresh whole American ginseng, add 0.5 times the amount of 0.15% citric acid solution to soak for 65 minutes, and then put it into pressure resistance The container was taken out under reduced pressure with a vacuum of 0.06 MPa for 25 minutes, the ginseng body was heated at 65° C. and pressurized by 0.1 MPa for 35 minutes, and the ginseng body was dried with hot air to obtain 1.2 kg of American ginseng with a water content of 5%. Submitted for inspection and tested various ginsenosides, and the content results are as follows:

[0010]

Embodiment 3

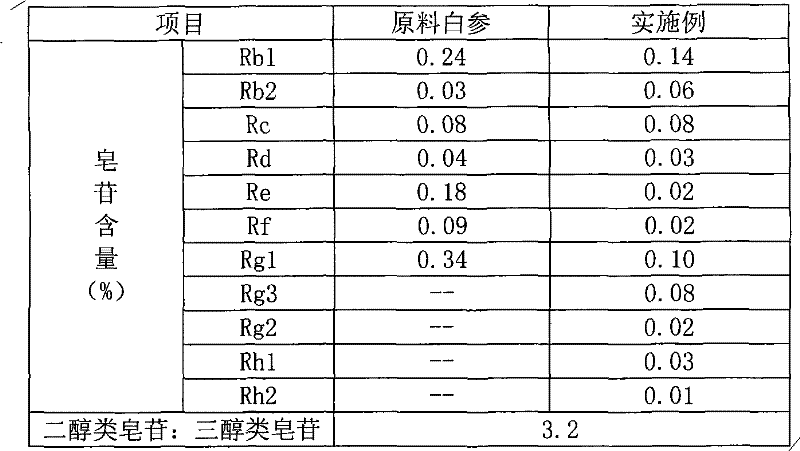

[0011] Example 3: Take 5.0 kg of fresh whole ginseng, add 0.5 times the amount of 1.5% pear juice to soak for 65 minutes, then put it in a pressure-resistant container and use a vacuum of 0.06 MPa to reduce pressure for 25 minutes and take it out. The pressure is 0.1MPa for 35 minutes, and the ginseng body is dried with hot air to obtain 1.3 kg of ginseng with a water content of 5%. Submitted for inspection and tested various ginsenosides, and the content results are as follows:

[0012]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com