Testing device of electronic label and its method

An electronic label and testing device technology is applied in the field of electronic label testing devices to achieve the effects of increasing convenience and practicability and improving reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

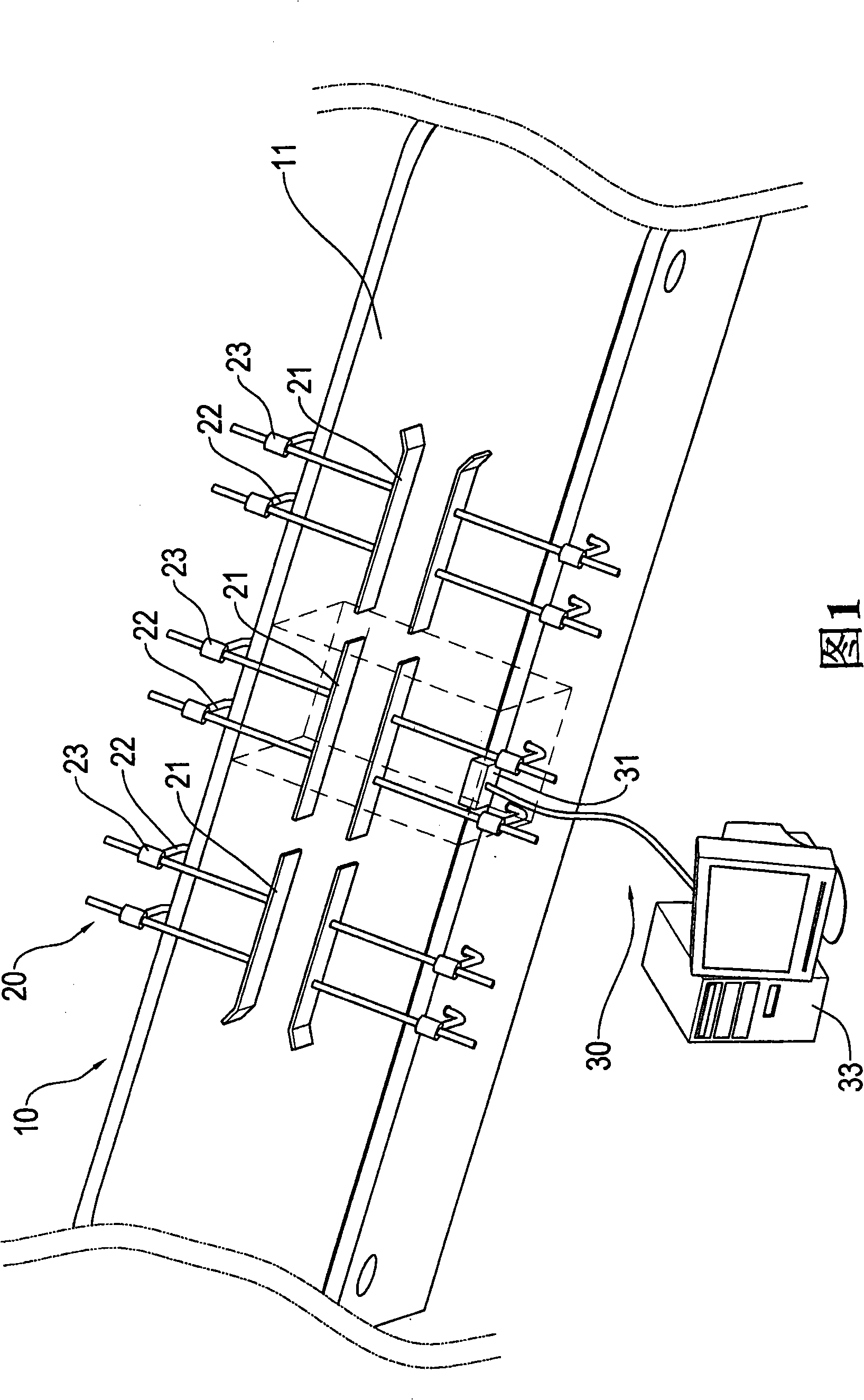

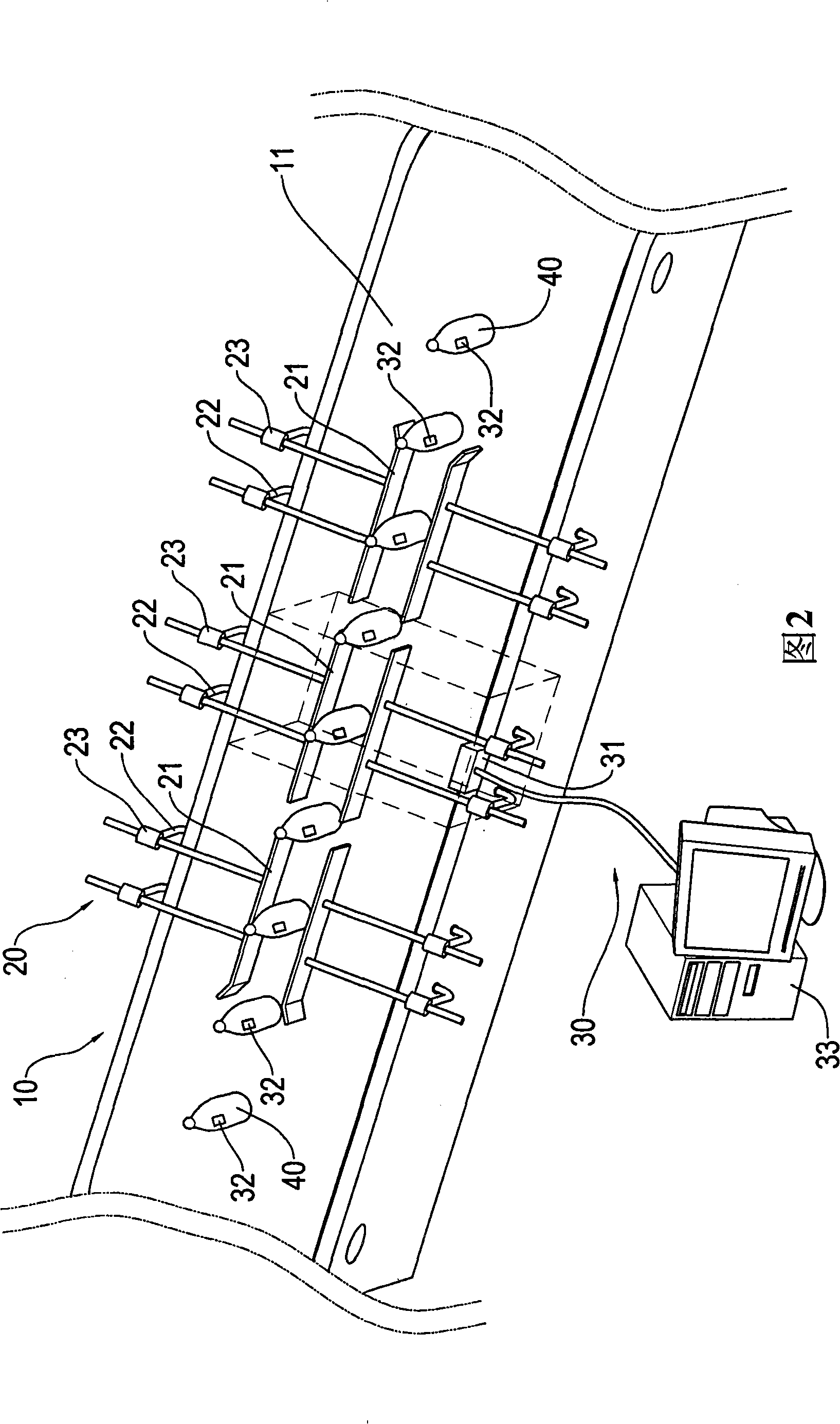

[0034] Please refer to shown in Fig. 1, it is the schematic structural diagram of the testing device of electronic label of the present invention, mainly comprises a conveying mechanism 10, a baffle mechanism 20 and a read-write system 30; This conveying mechanism 10 is provided with a conveyer belt 11, and this output belt 11 is an adjustable speed change, and the baffle mechanism 20 is provided with a traveling guide plate 21, a guide plate fixing seat 22 and a guide plate adjuster 23, and the traveling guide plate 21 is placed on the conveyor belt 11 of the conveying mechanism 10 , wherein one side of the advancing guide plate 21 is connected with a guide plate adjuster 23 to adjust the position of the advancing guide plate 21, and one end of the guide plate adjuster 23 is connected with the guide plate fixing seat 22, and the guide plate is fixed The seat 22 is fixed below the conveyor belt 11 for fixing the position of the traveling guide plate 21 . In addition, the read-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com