Production method of profiled silex glass holding bar and apparatus

A quartz glass and production method technology, applied in glass production, glass manufacturing equipment, glass molding, etc., can solve problems such as complex production process, low load-bearing strength, and large structural stress, and achieve simple process, high load-bearing strength, and internal uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

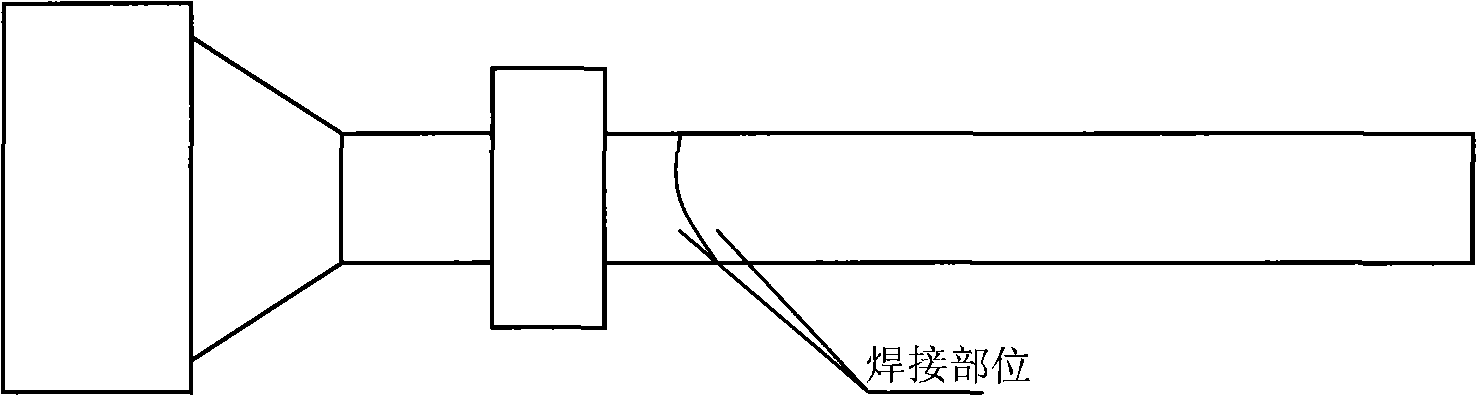

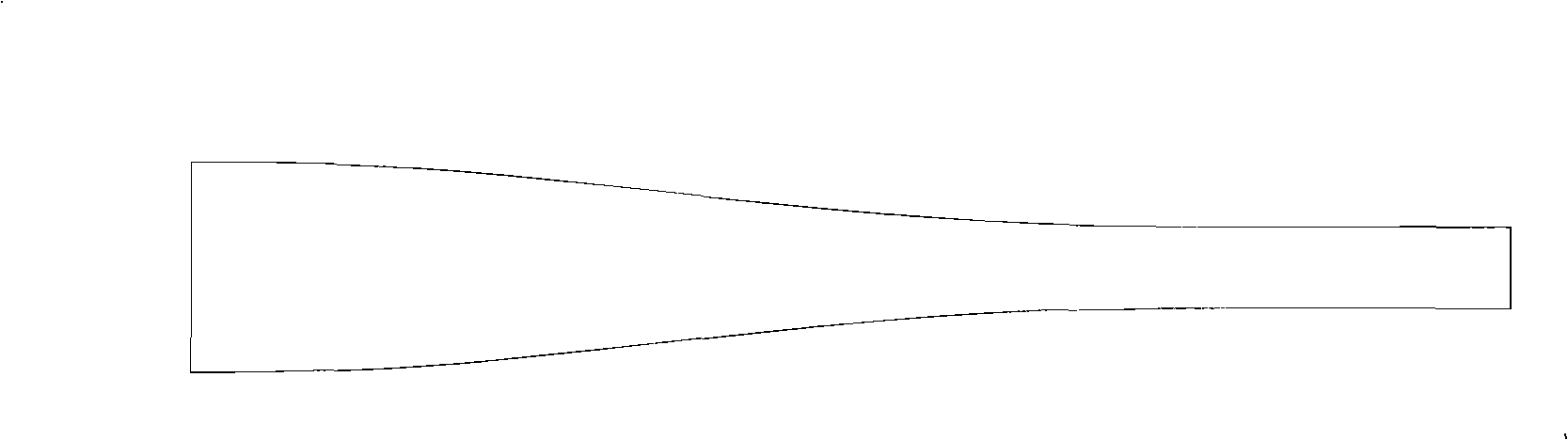

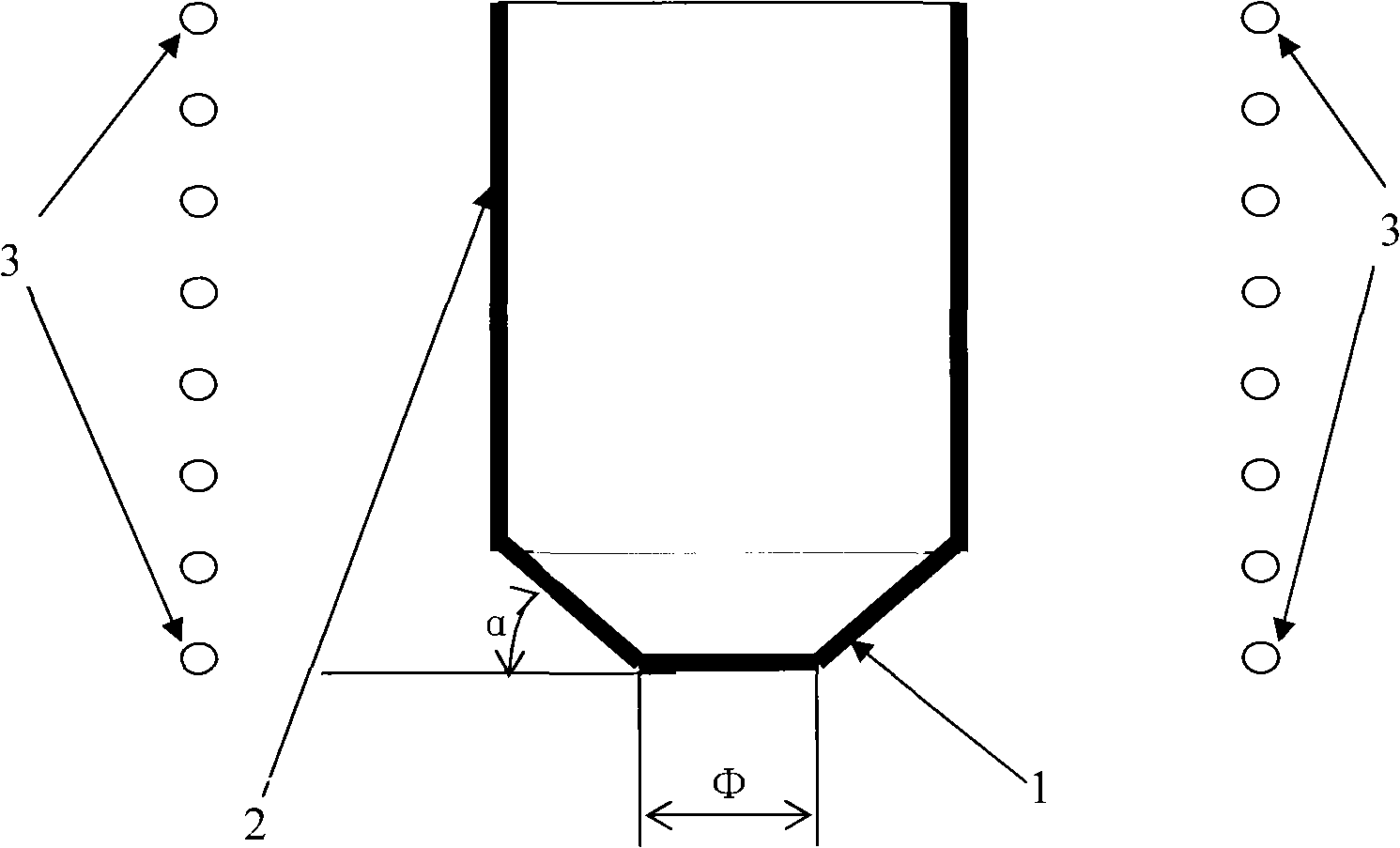

[0018] The production method of special-shaped quartz glass holding rod of the present invention, its preferred embodiment is as follows figure 2 Shown:

[0019] First, the quartz glass raw material is drawn into a special-shaped rod blank, and the diameter of one end of the special-shaped rod blank is larger than the diameter of the other end to form a large and small end special-shaped rod blank;

[0020] Then, the profiled rod blank is processed into a profiled rod of the desired shape. In this way, the structural defects caused by welding blank rods with different diameters can be avoided; and the defect of low yield rate caused by using large-diameter blank rods to process special-shaped rods can be avoided.

[0021] After the special-shaped rod blank is processed into a special-shaped rod of a required shape, flame polishing is also included on the processed special-shaped rod. The purpose of the flame polishing process is to eliminate small cracks on the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com