Optimizing hydrogenation and heat-exchange system

A technology of heat exchange system and hydrogenation reaction, applied in the field of heat exchange system, can solve the problems of high resource consumption, no energy saving, high energy consumption of the device, and achieve the effects of optimizing heat exchange network, reducing oil refining cost and saving heat source steam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

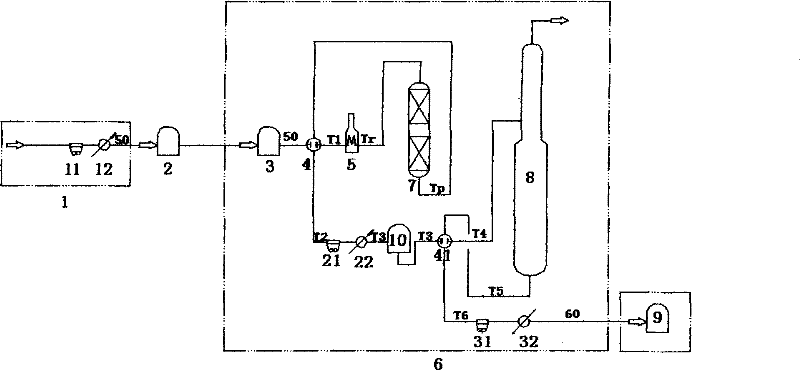

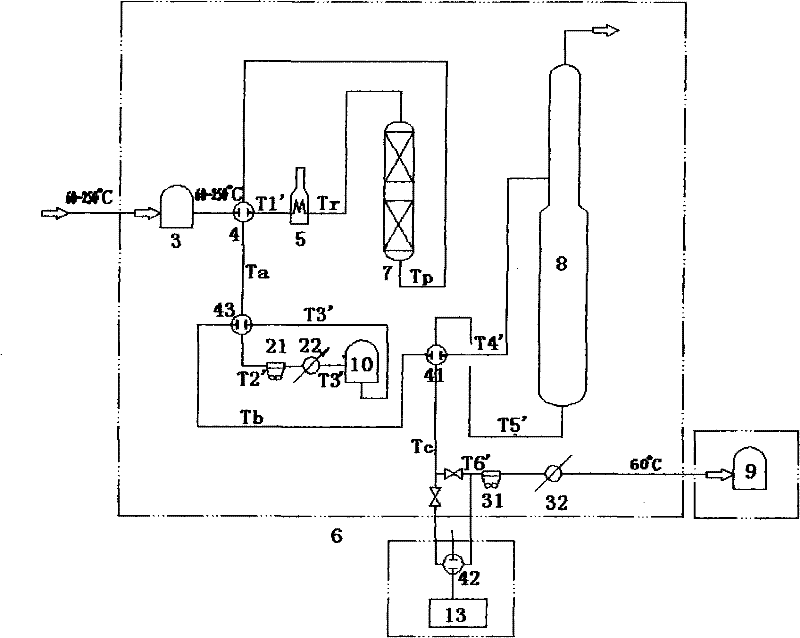

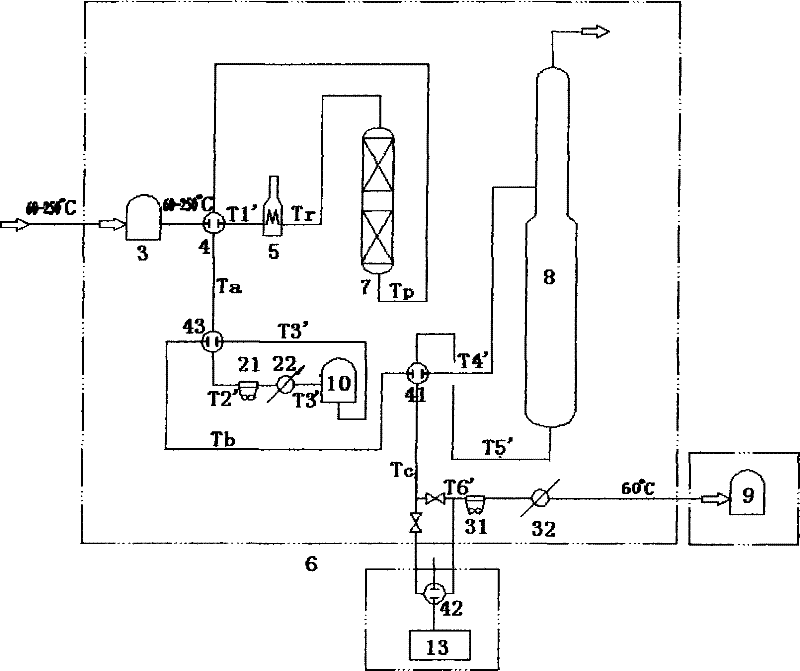

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below, and the present invention is relatively clear to those skilled in the art.

[0015] The device in this hydrogenation heat exchange system is a process device that reacts with hydrogen as the reaction raw material or in a hydrogen environment. The raw material oil at about 60-250 ° C is directly converted to 60 °C without cooling by the upstream device and the intermediate storage tank 2. The hot feed at around -250°C enters the raw oil buffer tank 3 of the hydrogenation unit 6, which strengthens the heat exchange between the feed and the pre-hydrogenation product, so that the final heat transfer temperature of the feed is changed from the original lower T 1 raised to T 1 ’, shrink T r with T 1 The temperature difference greatly reduces the load of the heating furnace 5, and finally saves the consumption of primary energy and fuel of the heating furnace 5;

[0016] The temperature out of the hydrogenation reactor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com