Polarizing plate with optical compensation layer, liquid crystal panel using polarizing plate with optical compensation layer, liquid crystal display unit, and image display unit

An optical compensation layer and liquid crystal panel technology, applied in the field of polarizers, can solve the problems of erosion of retardation film, white turbidity of retardation film, peeling of coating layer, etc., and achieve high contrast, prevent light leakage, and prevent uneven interference.

Inactive Publication Date: 2008-10-22

NITTO DENKO CORP

View PDF27 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the above-mentioned laminated retardation layer, the liquid crystal monomer is dissolved in an organic solvent and directly coated on the retardation film, so the organic solvent corrodes the retardation film, and as a result, the retardation film is damaged and the retardation film is damaged. The problem that the film becomes cloudy

In addition, since the coating layer of the liquid crystal is directly coated on the retardation film, the coating layer of the liquid crystal is easily peeled off from the retardation film, resulting in the problem that it is not practical (for example, high temperature and high humidity, etc.).

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Login to View More

Abstract

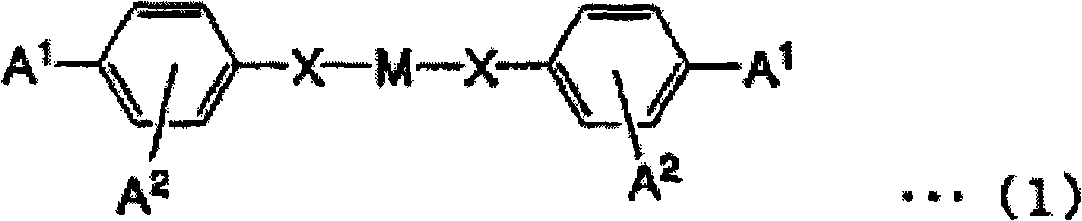

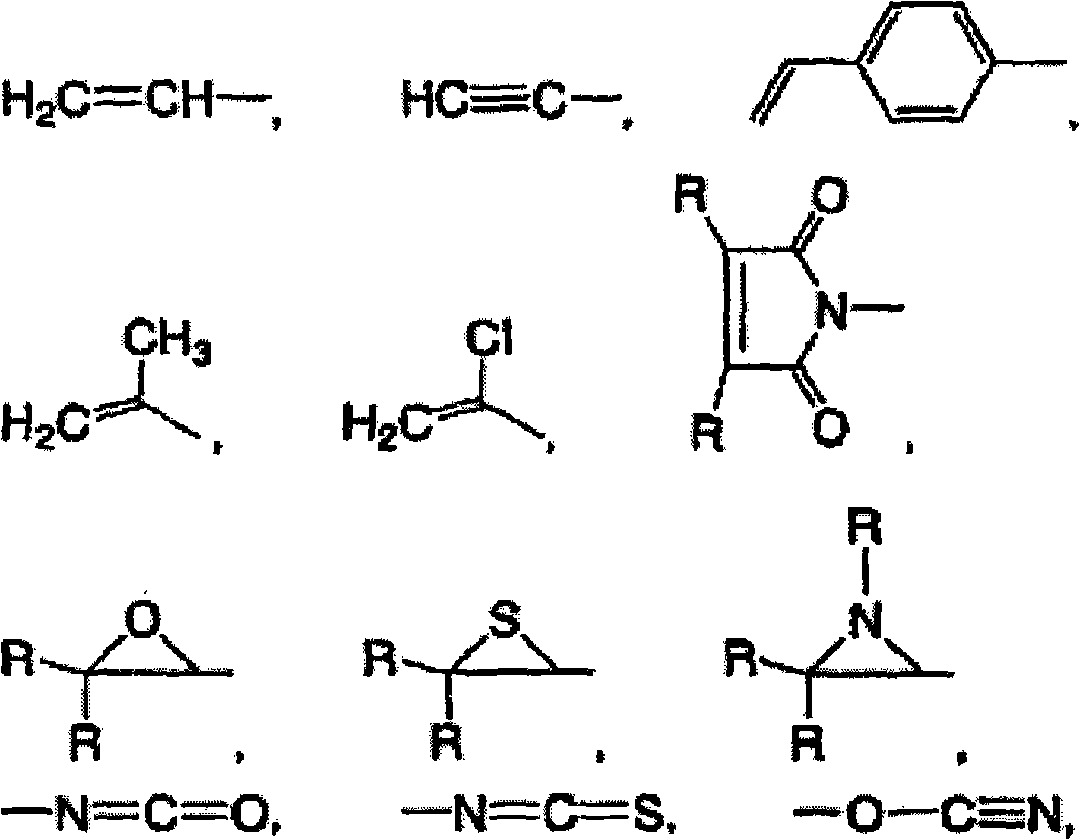

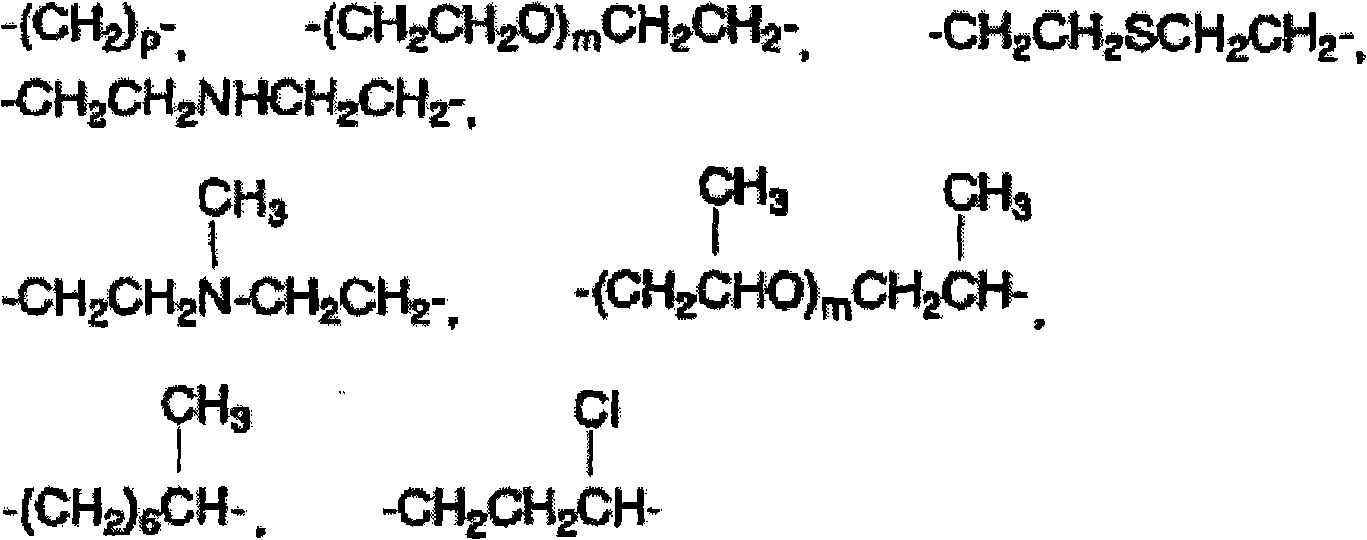

A polarizing plate with an optical compensation layer capable of contributing to its thinning, realizing high contrast with viewing angle characteristics improved, preventing interference non-uniformity and thermal non-uniformity, being limited in color shift, delivering a good color reproducing feature, and favorably preventing light leakage at black displaying; and a liquid crystal panel, a liquid crystal display unit and an image display unit using such a polarizing plate with an optical compensation layer. The polarizing plate with an optical compensation layer comprises a polarizer, a first optical compensation layer, an adhesive layer, and a second optical compensation layer sequentially in the order mentioned, wherein the first optical compensation layer has a refractive index distribution, nx>ny=nz, with its in-plane phase difference Re1 exhibiting wavelength dispersion characteristics that gradually decrease toward a short-wavelength side and with its in-plane phase difference Re1 being 90-160 nm, and the second optical compensation layer is a coating layer, has a refractive index distribution, nx=ny>nz, with its in-phase difference Re2 being 0-20 nm, its phase difference Rth2 in thickness direction being 30-300 nm and its thickness being 0.5-10 [mu]m.

Description

Polarizer with optical compensation layer, liquid crystal panel using polarizer with optical compensation layer, liquid crystal display device, and image display device technical field The invention relates to a polarizer with an optical compensation layer, a liquid crystal panel using the polarizer with an optical compensation layer, a liquid crystal display device and an image display device. More specifically, the present invention relates to a polarizer with an optical compensation layer that contributes to thinning, prevents thermal unevenness, and can well prevent light leakage during black display, and a polarizer using the above-mentioned optical compensation layer. Mirror liquid crystal panels, liquid crystal display devices, and image display devices. Background technique As a VA-mode liquid crystal display device, in addition to a transmissive liquid crystal display device and a reflective liquid crystal display device, a transflective liquid crystal display dev...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B5/30G02F1/1335G02F1/13363

Inventor 首藤俊介石原洋司长濑纯一

Owner NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com