Liquid immersion microscope

A microscope and liquid immersion technology, applied in microscopes, optics, instruments, etc., can solve the problem of not being able to observe the substrate by liquid immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

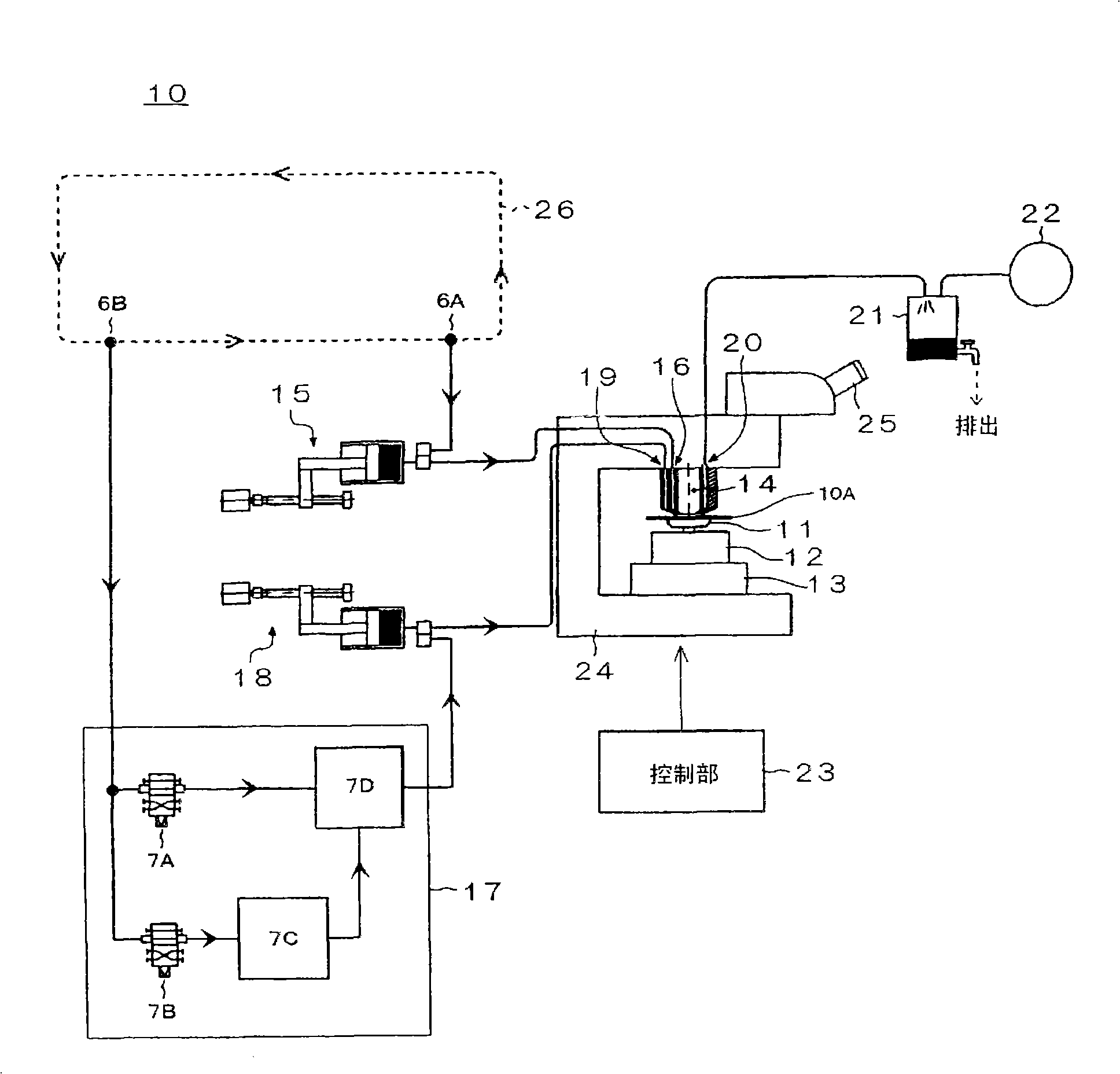

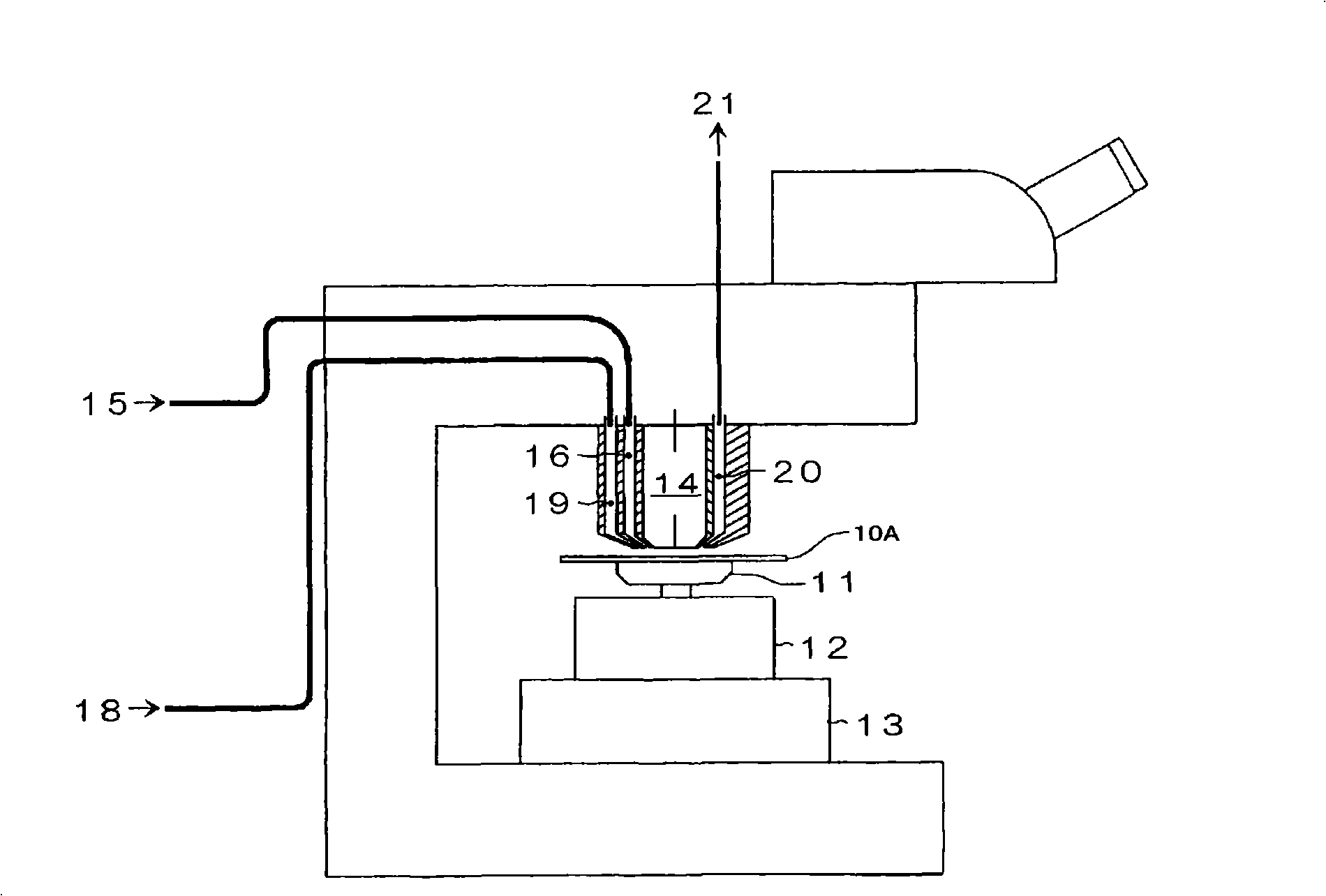

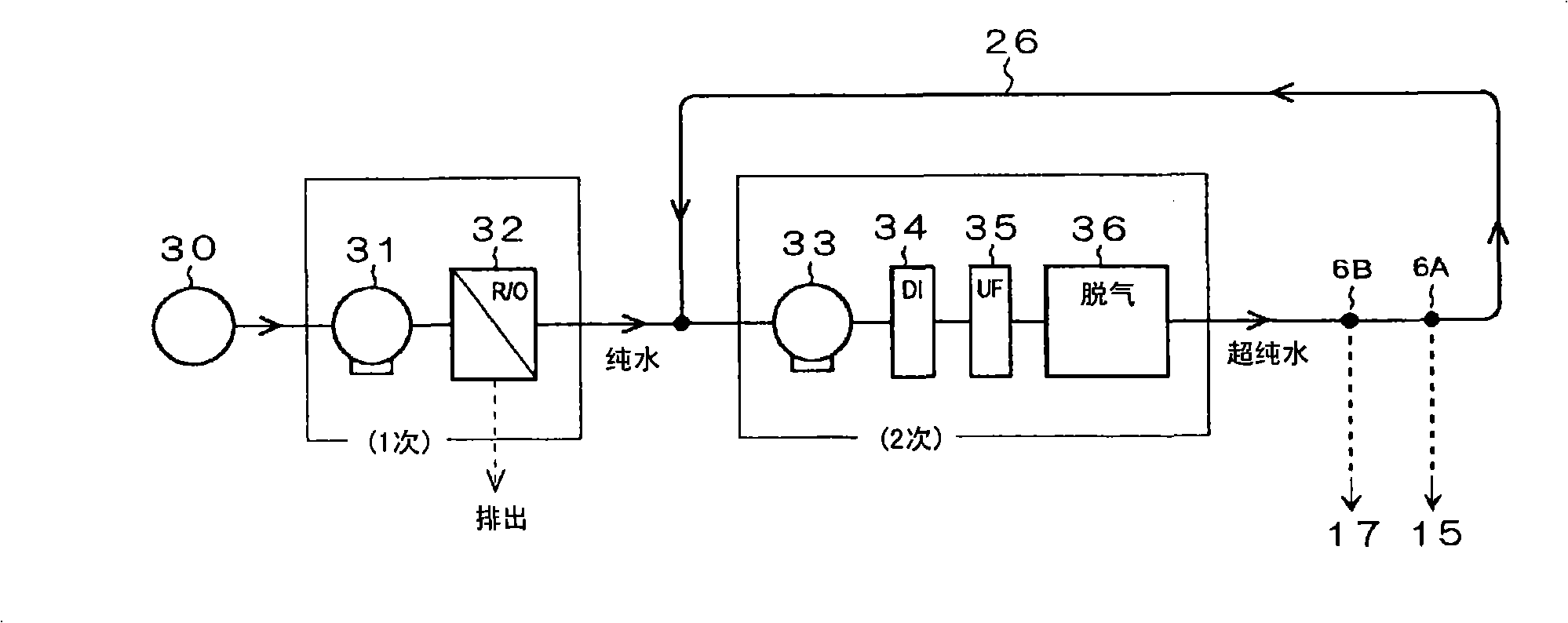

[0015] In the liquid immersion microscope device 10 of this embodiment, as figure 1 As shown, there are stage parts (11-13) for supporting the substrate 10A to be observed, a liquid immersion objective lens 14, a mechanism (15, 16) for supplying liquid for observation, and a liquid for cleaning. Mechanisms (17-19) for supplying, mechanisms (20-22) for removing these liquids, and a control unit 23 for controlling each unit.

[0016] In addition, in the liquid immersion microscope device 10 , although not shown, an automatic transport illumination optical system or an observation optical system, a mechanism for the substrate 10A, a TTL autofocus mechanism, and the like are also provided.

[0017] The substrate 10A is a semiconductor wafer, a liquid crystal substrate, or the like. The liquid immersion microscope device 10 is a device for performing liquid immer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com