Clamping apparatus for wire-electrode cutting to process operation air gap of servo valve torque-motor

A torque motor and servo valve technology, which is applied in the field of on-line cutting and machining of the working air gap of the servo valve torque motor fixture, can solve the problems of low grinding efficiency and difficulty in ensuring product consistency, and achieve the effect of ensuring consistency and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

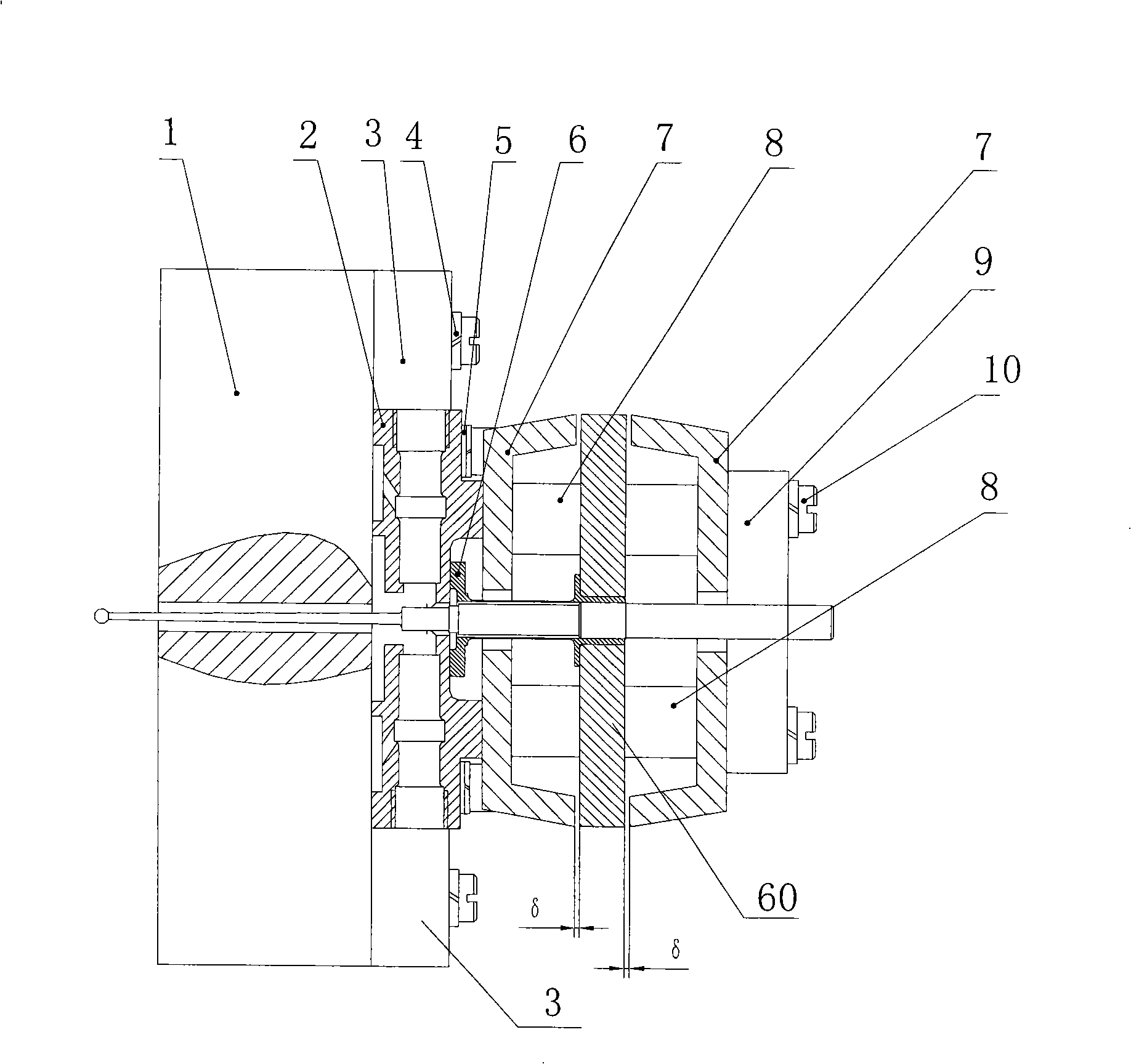

[0011] Please refer to Fig. 1, the fixture for the working air gap of servo valve torque motor in wire cutting according to the present invention, wherein the torque motor includes armature assembly 6, magnetic steel 8, upper and lower magnet conductors 7, primary seat 2, and screw 10 and platen 9. Among them, the armature assembly 8 of the torque motor is fixed on the primary seat 2; the magnetic steel 8 is supported between the upper and lower magnetizers 7; the pressure plate 9 is pressed on the outer end of the lower magnetizer 7 and the pressure plate 9, the upper and lower The magnetic conductor 7 and the magnetic steel 8 are tightly connected together to form an incomplete torque motor; the working air gap to be processed is the gap between the upper and lower magnetic conductor 7 and the two ends of the armature 60 in the armature assembly 6. .

[0012] The fixture is composed of pad 1 and limit block 3. Wherein the pad 1 of the fixture is fixed on the bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com