Light car drive axle assembly assembling product line

A technology of drive axle assembly and assembly line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

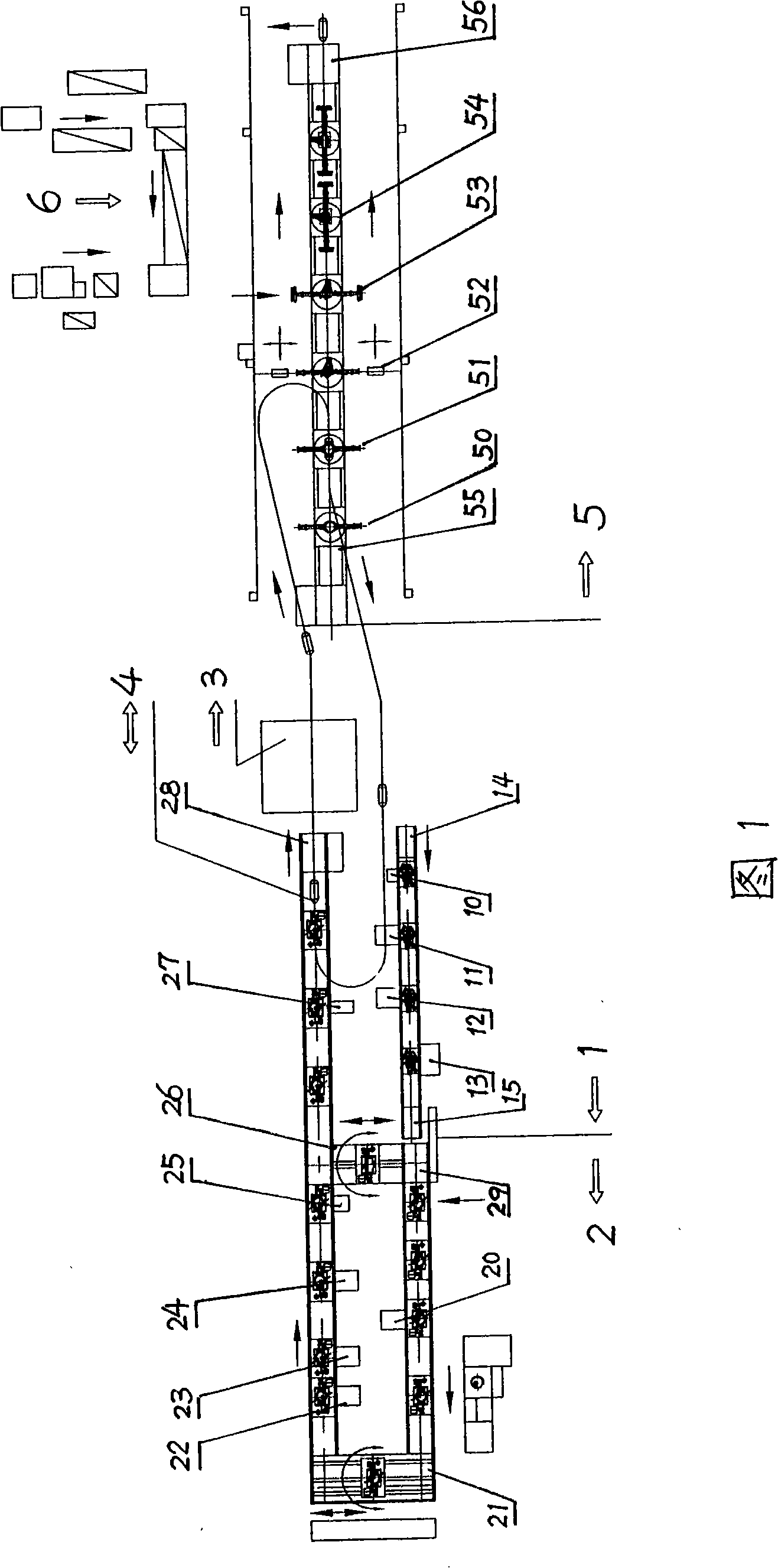

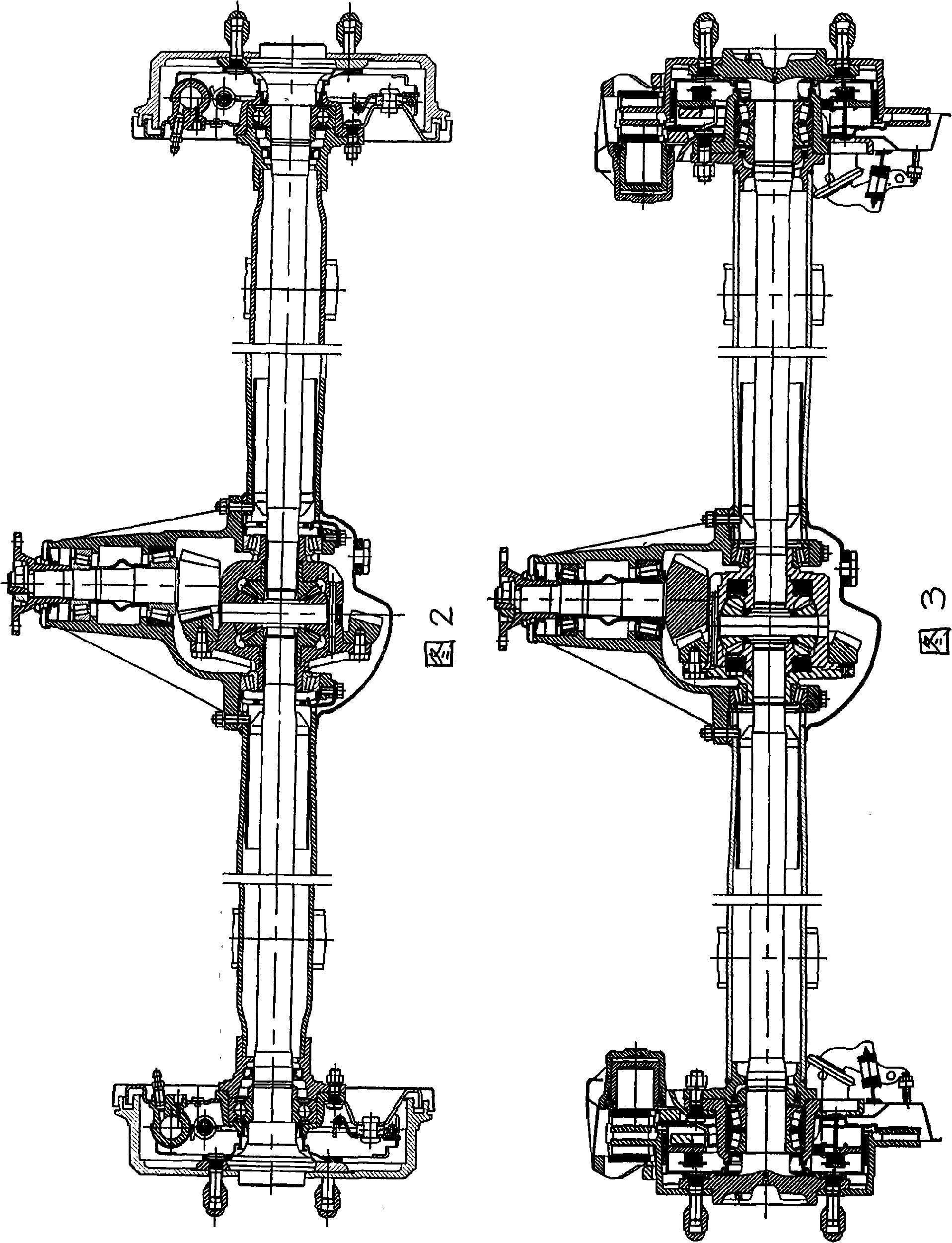

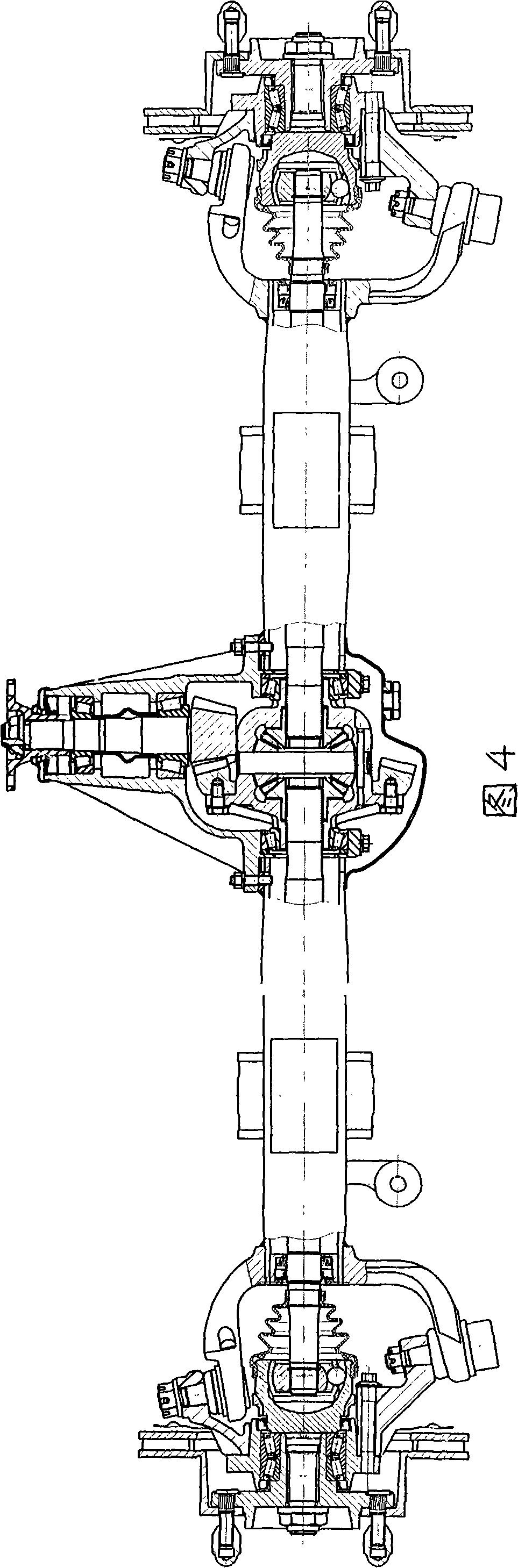

[0011] The layout of the light vehicle drive axle assembly assembly line provided by the patent application of the present invention is shown in Figure 1. It includes a linearly arranged differential subassembly assembly line 1 and a closed-loop final drive assembly assembly line. Line 2, the drive axle assembly overall assembly line 5 arranged in a straight line, the half shaft and brake sub-assembly assembly line 6 is connected to the drive axle assembly overall assembly line 5 side, the main reducer assembly operation test bench and soundproof room 3 It is installed at the lower end of the main reducer assembly line 2. Both the differential subassembly assembly line 1 and the main reducer assembly assembly line 2 are equipped with an upper assembly channel and a lower return channel, and the upper assembly channel and the lower return channel are realized by the elevators 14, 15, 28, 29 to assemble the fixture accompanying the pallet The automatic return of the drive axle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com