Method and device for acoustic cavitation and titanium dioxide nano particle controlling boiling and heat conduction

A nanoparticle and titanium dioxide technology, applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as boiling heat transfer enhancement and boiling heat hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

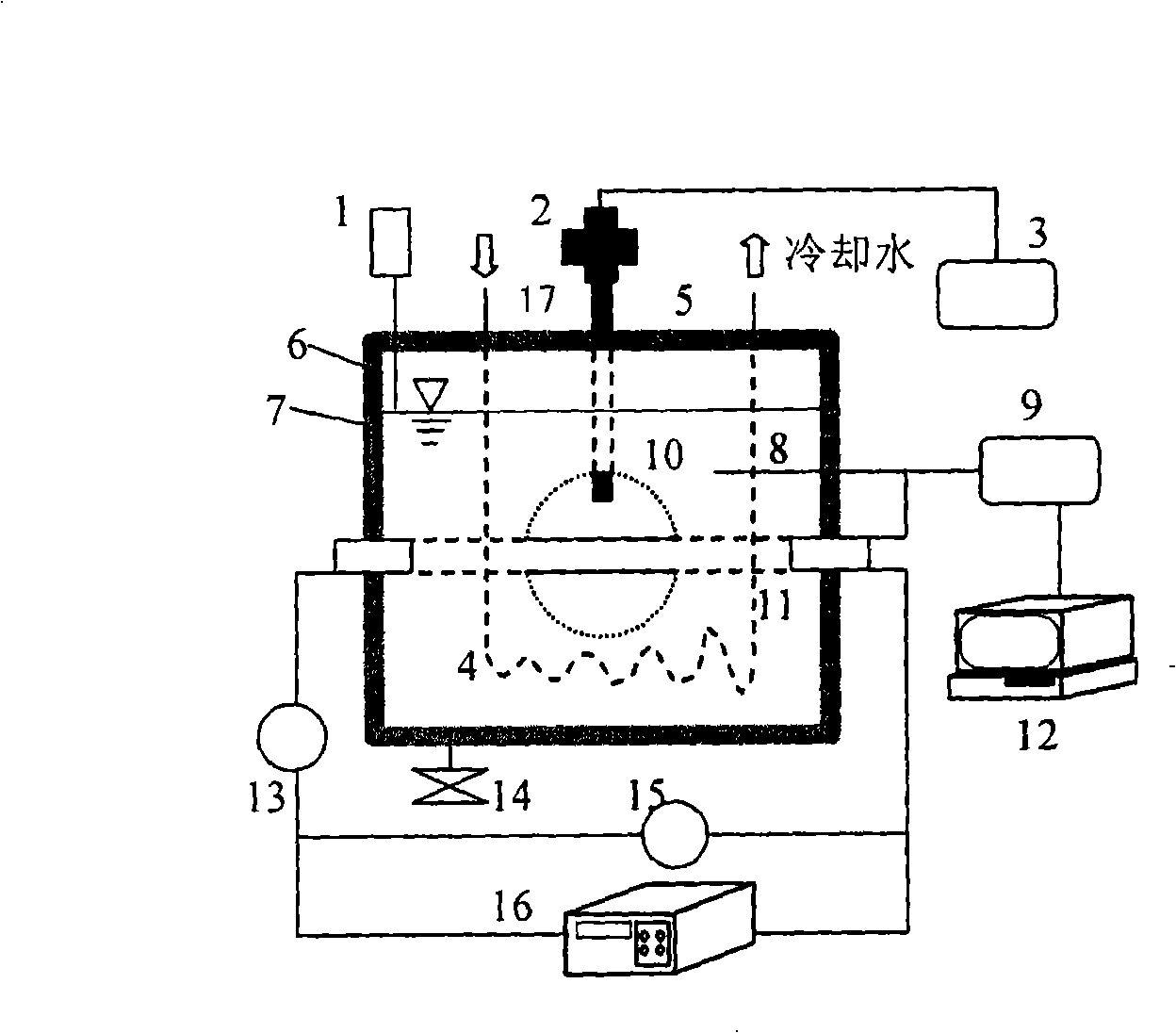

[0051] See figure 1 , is the device used in the method of the present invention, including a closed cavity 6, a heat exchange element 11, a condenser 4, an ultrasonic transducer 2, a pressure measuring device 1, a temperature measuring device, a liquid working medium, a power supply 16 and a computer 12; in,

[0052] An airtight stainless steel cavity 6 is covered with an insulating layer 7 on the outer surface, and a certain volume of dielectric liquid is filled in the cavity 6. There are pressure measuring devices 1, temperature measuring devices, observation holes 10, thermocouples 8 and Leakage ball valve 14, the installation holes of the two heat exchange parts are on the left and right side walls of the cavity 6, and the installation holes of the ultrasonic transducer are on the top wall of the cavity 6;

[0053] A heat exchange element 11 is horizontally installed in the middle of the cavity 6 and submerged in the liquid. connection, an ammeter 13 is connected in seri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com