Pneumatic clutch controlling permanent magnetic retarder

A pneumatic clutch and control technology, applied in the direction of permanent magnet clutch/brake, control electromechanical brake, control system, etc., can solve the problems of dirty degaussing, high fuel consumption, increased energy consumption of automobiles, etc., and achieve fast response, The effect of long service life and compact structure

Inactive Publication Date: 2008-10-29

扬州市洪泉实业有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At the same time, the response of the cylinder is slow, which cannot meet the requirements of automobile braking, especially the permanent magnet retarder with high torque.

In addition, this kind of permanent magnet retarder has a magnetic flux leakage phenomenon (degaussing is not clean), and there is still a reverse braking torque when there is no need for braking, resulting in increased energy consumption and fuel consumption of the vehicle, making many drivers unwilling use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

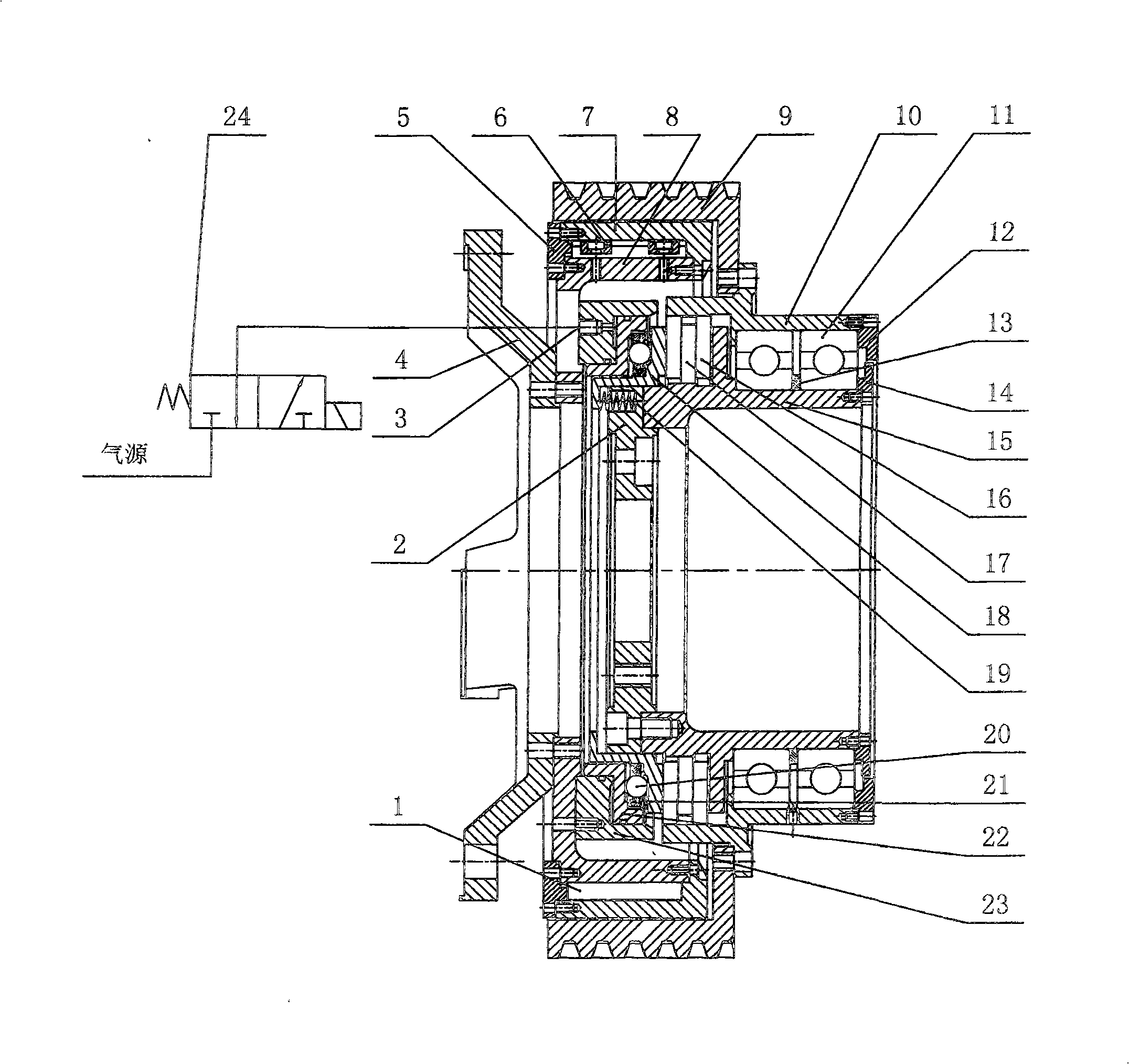

The invention provides a pneumatic clutch control type permanent magnetism retarder, which relates to a permanent magnetism retarder which comprises a stator and a rotor, wherein, the stator comprises a stator frame, a magnet support, a magnet external holder, a permanent magnet; the rotor comprises a rotor disk and a flange, and the rotor disk and the flange are connected by a clutch device which has the same axis with the rotor disk; the permanent magnet is fixed on the magnet support. Under the normal driving state of a vehicle, the rotor disk does not rotate, does not generate eddy current which hinders the movement of a transmission shaft and does not generate heat. When speed is need to be lowered, the pneumatic clutch starts to work and the rotor disk rotates to realize speed slowing. By utilizing the pneumatic clutch to carry out control, the rotor does not rotate under non-working sate; therefore, the invention has the advantages of requiring no degaussing, no reverse braking torque when in no braking state, energy-saving, large torque moment, high reaction speed, compact structure, safety and long service life.

Description

Pneumatic clutch controlled permanent magnet retarder technical field The invention relates to an automobile retarder, in particular to a permanent magnet retarder. Background technique Automobile retarder is a kind of automobile braking auxiliary device that has been widely used in China in recent years. At present, it is mainly eddy current retarder. Other forms of retarder include hydraulic retarder, permanent magnet retarder, Generator retarder, exhaust brake retarder, etc. Among them, the permanent magnet retarder is gradually favored by users due to its advantages of light weight, no energy consumption, no loss, and maintenance-free. The permanent magnet retarder is an upgraded product of the eddy current retarder, which uses a permanent magnet to replace the coil and iron core used in the eddy current retarder to generate a magnetic field. The rotor disk rotates and cuts the magnetic field lines, thereby generating eddy currents and braking torques to achieve the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02K49/10H02P15/00H02P15/02

Inventor 孙祥王江淮

Owner 扬州市洪泉实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com