Light aggregate shale porcelain granule and production method thereof

A technology of shale ceramsite and its production method, which is applied in the fields of ceramsite products and its production, light aggregate shale ceramsite and its production, and can solve the constraints on the production and application of light wall materials, the limitation of the amount of waste slag added, Affect the strength of the plate and other issues, and achieve the effects of environmental protection, long natural vibration period, and good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

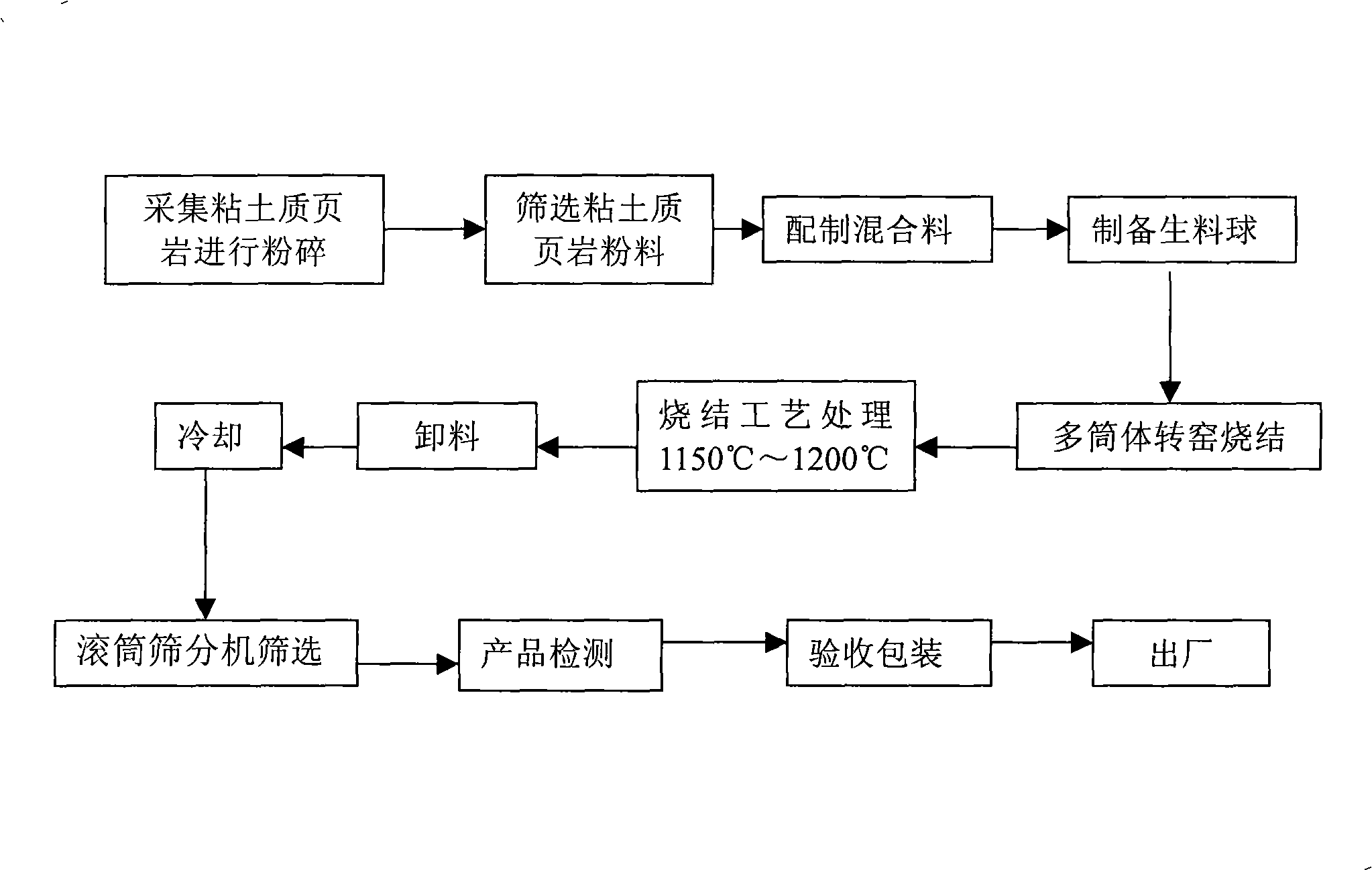

Method used

Image

Examples

Embodiment 1

[0037] The clayey shale is collected by conventional methods, and crushed by conventional coarse powder and fine powder crushing machines. After crushing for 2 to 5 minutes, continue the following steps:

[0038] 1) Screen out shale powder with a particle size of 200-280 mesh;

[0039] 2) Take 90 parts of shale powder screened in step 1), 5 parts of fly ash, 1 part of additive mixed with ore washing sludge, boron mud, and sodium nitrate waste residue in a ratio of 1:1, and 4 parts of water and mix evenly Then put it into the mixer and stir it into a mixture; the stirring time is 3 to 5 minutes;

[0040] 3) Unload the mixture described in step 2) from the mixer, put it into the ball making machine, and unload it after making raw meal pellets with a particle size of Φ3-24mm after 3 minutes;

[0041] 4) The raw meal pellets unloaded in step 3) are directly put into a multi-cylinder rotary kiln. The multi-cylinder rotary kiln is composed of 4 kilns with different diameters connec...

Embodiment 2

[0044] The clayey shale is collected by conventional methods, crushed by conventional coarse powder and fine powder crushing machines, and after crushing for 2 to 5 minutes, the following steps are carried out:

[0045] 1) Screen out shale powder with a particle size of 200-280 mesh;

[0046] 2) Take 75 parts of shale powder screened in step 1), 10 parts of fly ash, 16 parts of additives mixed with boron mud and sodium nitrate waste residue in a ratio of 1:1, and 9 parts of water, mix them evenly and put them into the mixer , stirred into a mixture; the stirring time is 3 to 5 minutes;

[0047] 3) Unload the mixture described in step 2) from the mixer, put it into the ball making machine, and unload it after 5 minutes to make raw meal pellets with a particle size of Φ3-24mm;

[0048] 4) The raw meal pellets unloaded in step 3) are directly put into a multi-cylinder rotary kiln. The multi-cylinder rotary kiln is composed of 4 kilns with different diameters connected to each ot...

Embodiment 3

[0051] The clayey shale is collected by conventional methods, crushed by conventional coarse powder and fine powder crushing machines, and after crushing for 2 to 5 minutes, the following steps are carried out:

[0052] 1) Screen out shale powder with a particle size of 200-280 mesh;

[0053] 2) Take 45 parts of shale powder screened in step 1), 30 parts of fly ash, 10 parts of additives mixed with sodium nitrate waste residue, iron dioxide waste residue and ore washing sludge in a ratio of 1:1:1, water After 15 parts are mixed evenly, put them into the mixer and stir them into a mixture; the stirring time is 3 minutes;

[0054] 3) Unload the mixture described in step 2) from the mixer, put it into the ball making machine, and unload it after making raw meal pellets with a particle size of Φ3-24mm after 4 minutes;

[0055] 4) The raw meal pellets unloaded in step 3) are directly put into a multi-cylinder rotary kiln. The multi-cylinder rotary kiln is composed of 4 kilns with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com