Polyurethane fireproof blocking material, preparation and use thereof

A technology of fireproof blockage and application method, which is applied in fire rescue and other directions, can solve the problems of increased maintenance costs, high overall cost, and difficulty in sealing tightly, etc., and achieves the effects of good construction characteristics, long service life, and good environmental protection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a polyurethane fireproof blocking material, including:

[0029] The polyurethane fireproof blockage is a soft elastic or rigid polyurethane fireproof blockage made by mixing and stirring polyisocyanate containing flame retardants and polyether polyols in proportion, and undergoing chemical reaction, foaming, expansion and curing. Combustion agent is composed of various inorganic substances containing nitrogen, phosphorus, carbon and calcium.

[0030] The closed cell content in the foam structure of the rigid polyurethane foam provided in this embodiment is greater than 90%, and the water absorption rate is low, generally below 2%. It has good waterproof and anti-corrosion properties.

Embodiment 2

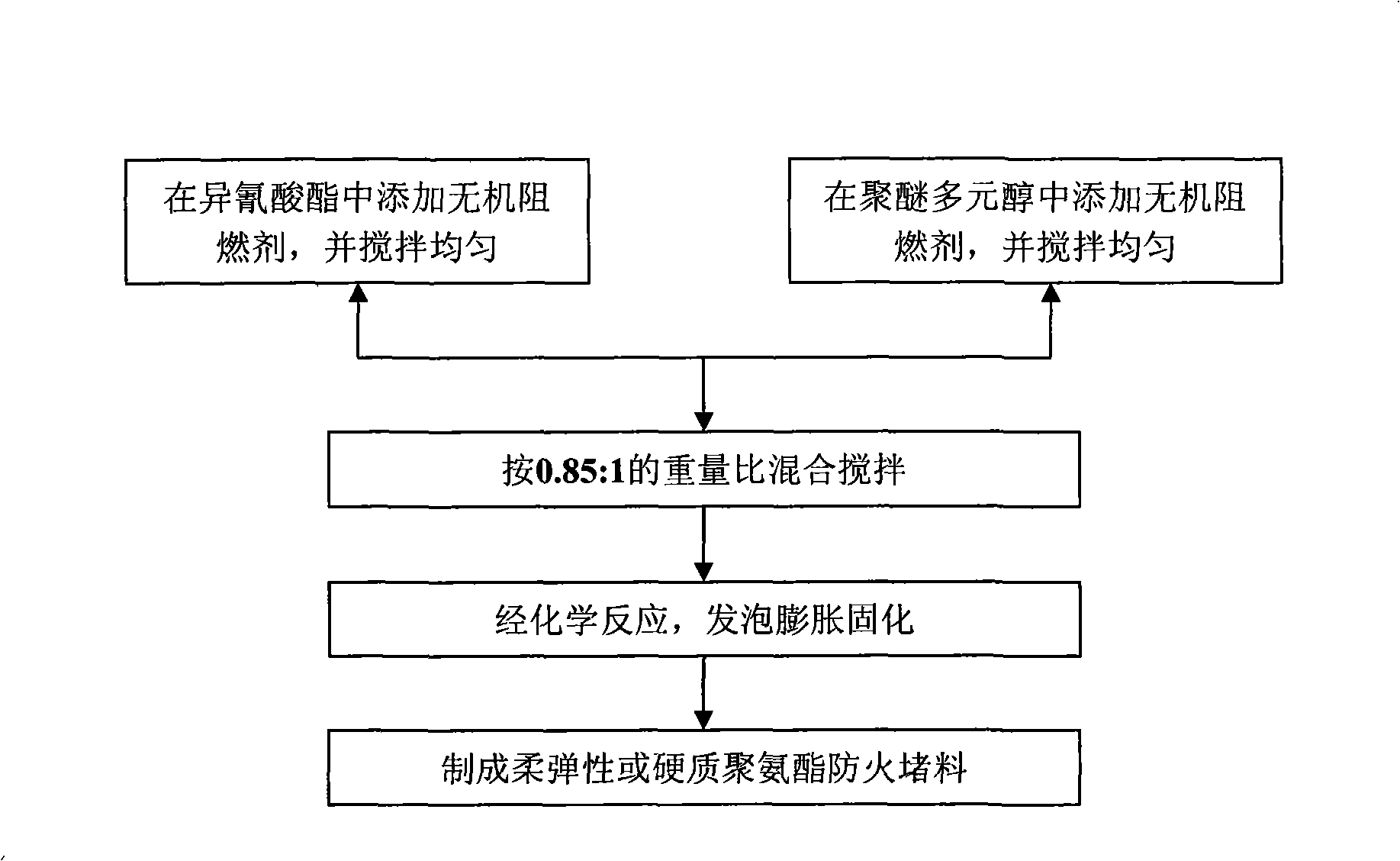

[0032] Such as figure 1 As shown, the preparation method of polyurethane fireproof blocking material provided in this embodiment, its steps mainly include:

[0033] Add 5-12% by weight of inorganic flame retardant to polyisocyanate and stir evenly;

[0034] Add 18-42% by weight of inorganic flame retardant to polyether polyol and stir evenly;

[0035] Mix and stir polyisocyanate containing flame retardant and polyether polyol at a weight ratio of 0.85:1, undergo chemical reaction, expand and solidify after foaming, and make flexible elastic or rigid polyurethane fireproof blocking material.

[0036] The density of the flexible and elastic polyurethane fireproof blockage is 200kg / m 3 ~250kg / m 3 , the density of rigid polyurethane fireproof blockage is 80kg / m 3 ~100kg / m 3 .

Embodiment 3

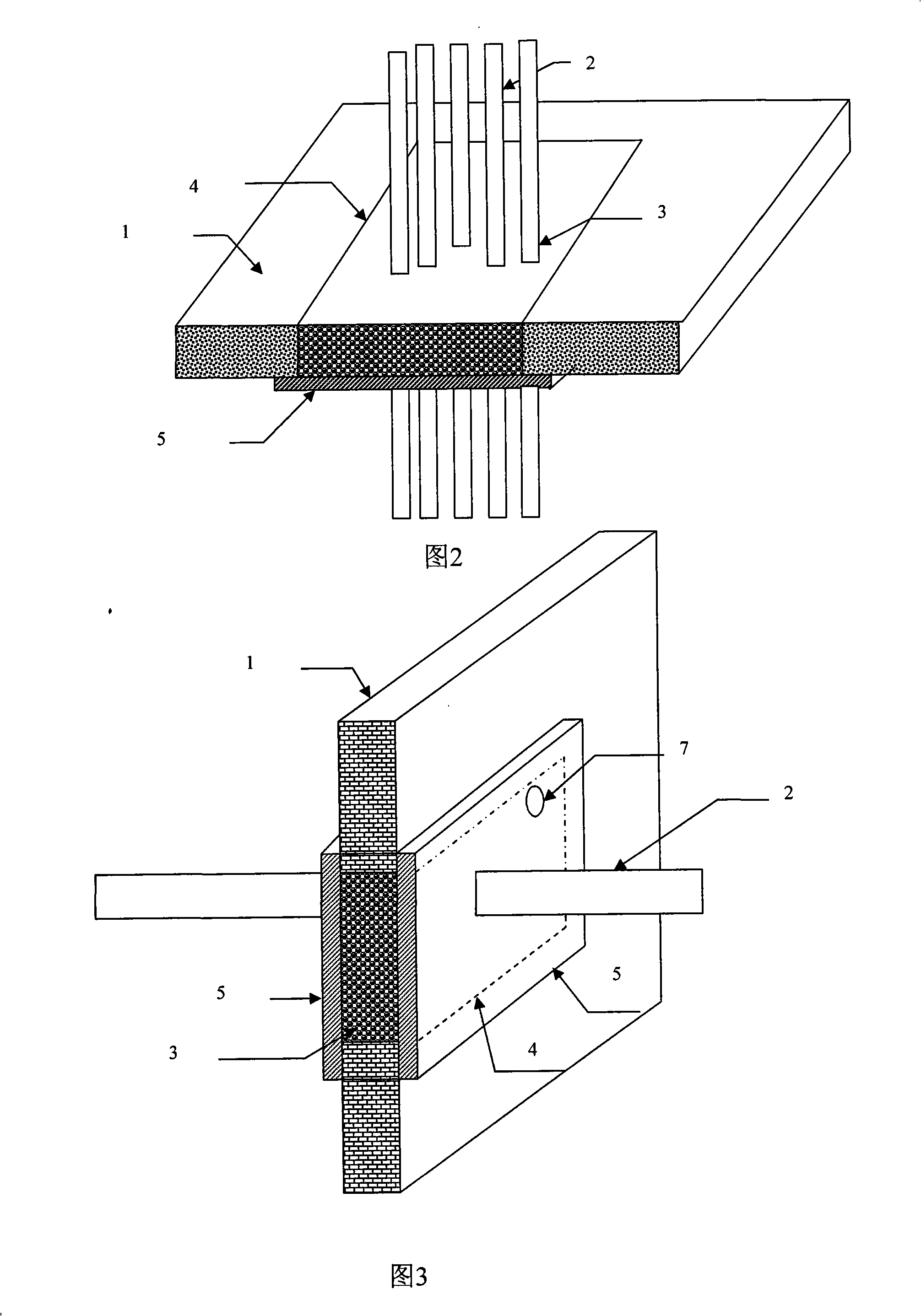

[0038] This embodiment provides an application method of polyurethane fireproof blockage,

[0039] It is to set up simple templates in the parts that need to be protected.

[0040] Mix and stir the polyisocyanate containing flame retardant and polyether polyol in a weight ratio of 0.85:1 using special machinery or manual operation;

[0041] When the mixed liquid has not yet foamed and expanded, pour or spray the liquid material between the parts that need to be protected. The liquid material flows freely and foams and expands to tightly fill the space of the part that needs to be protected. After curing, it will be demoulded. The parts that need to be protected form a strong and seamless flame-retardant protective layer.

[0042] Among them, if the opening of the base body that needs to be filled with polyurethane fireproof blockage needs to be blocked, the formwork is enclosed at the part of the base opening that needs to be protected, and a pouring port is set on the formwo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com