Method for changing old simple supported beam bridge into continuous beam bridge

A technology of supported girder bridge and simply supported girder is applied in the field of transforming old simply supported girder bridges into continuous girder bridges, which can solve the problems of many expansion joints, inability to improve the rigidity of components, and frequent driving bumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

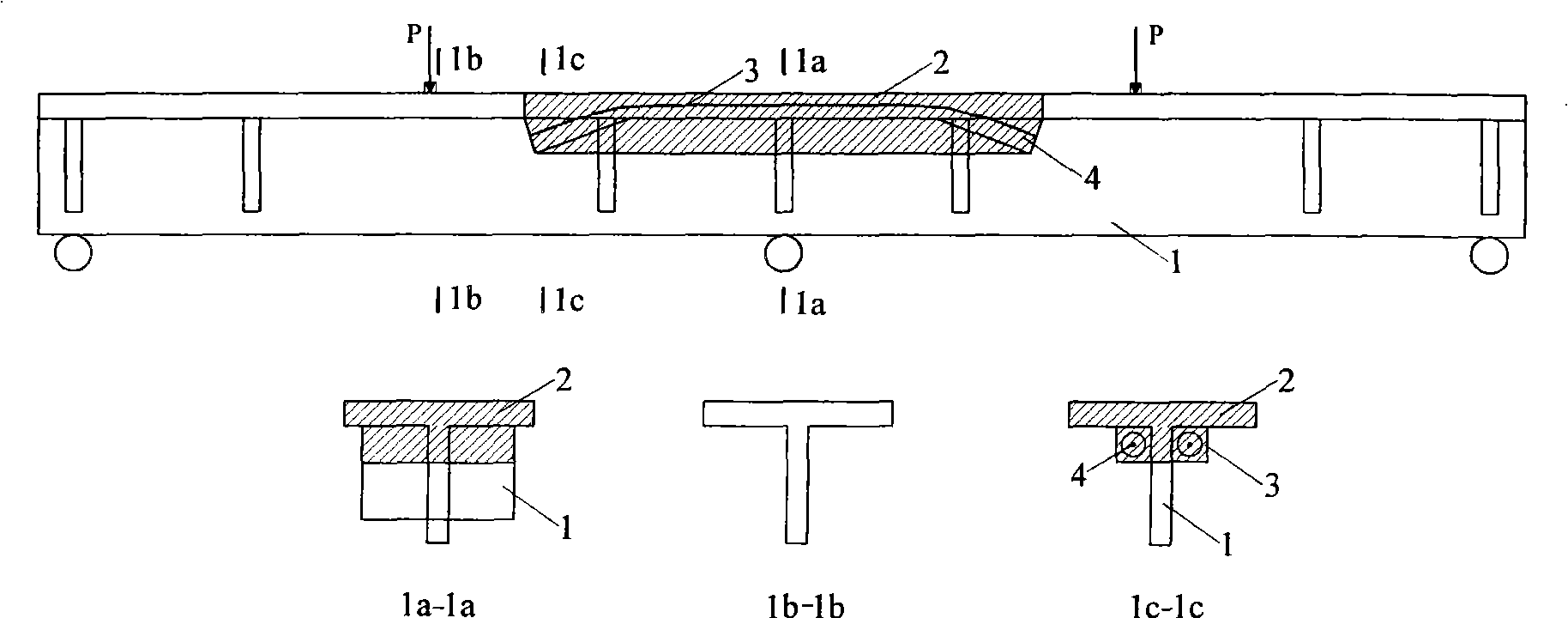

[0026] A method of converting an old simply supported girder bridge into a continuous girder bridge:

[0027] a. First chisel out the bridge deck concrete within the range where the old simply supported beams need to be connected,

[0028] b. Set the tooth plate in the chiseled area of the reinforced concrete T-beam and the tooth plate is located on both sides of the web, and the metal bellows is embedded in the tooth plate,

[0029] c. Pass the steel strand through the metal bellows, one end is anchored, and the other end is used as the tension end. The number of bundles of the steel strand is calculated and determined according to the predetermined prestress.

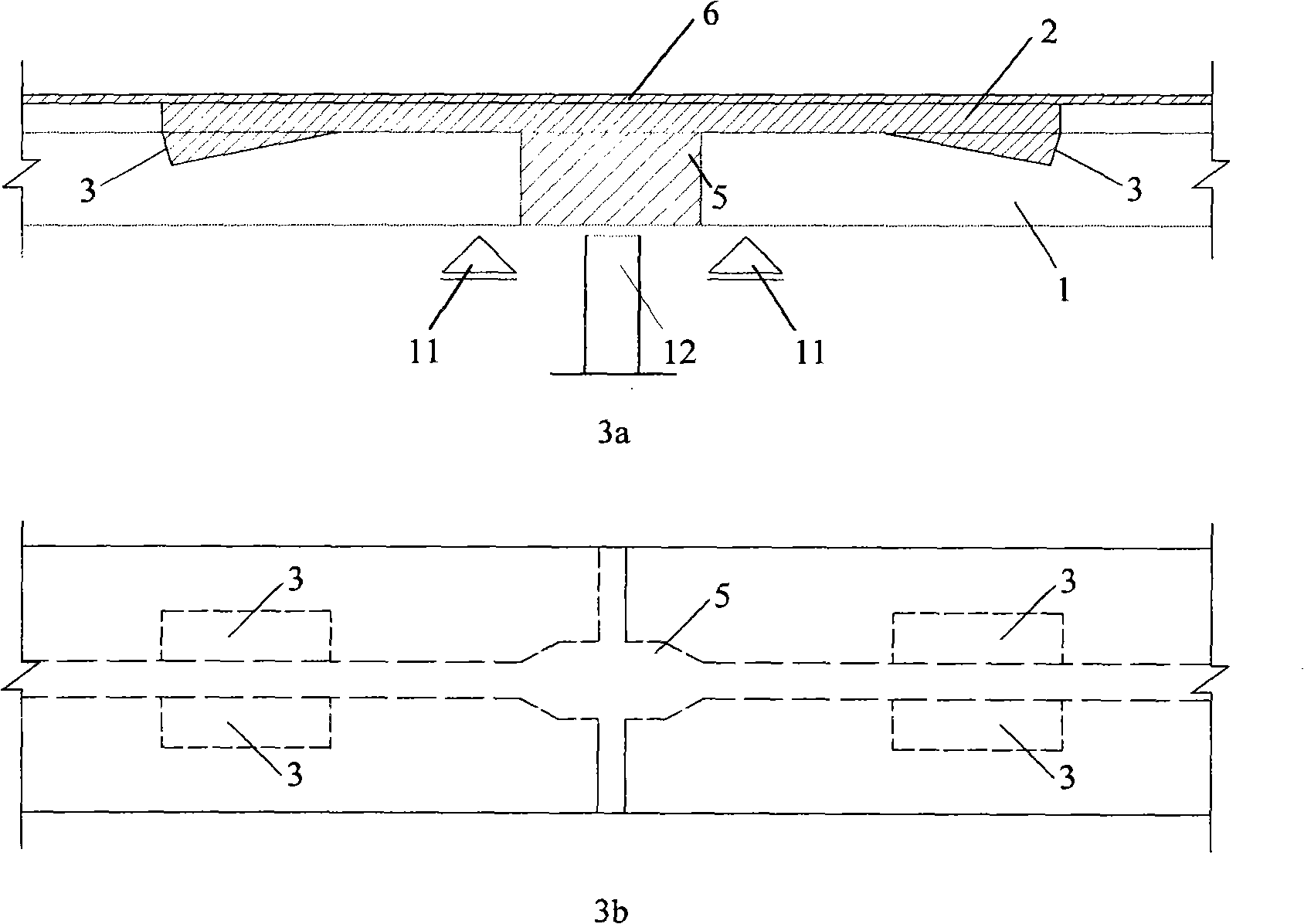

[0030] d. Widen the to-be-connected end of the T-beam, and install a diaphragm in the gap between the to-be-connected T-beams, pour concrete at the connected end and the bridge deck,

[0031] e. After the newly poured concrete reaches the design tensile strength, the steel strand is tensioned and anchored, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com