Rotating angular acceleration sensor

A technology of acceleration sensor and rotation angle, which is applied in directions such as acceleration measurement using inertial force, and can solve problems such as inability to measure rotation angular acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

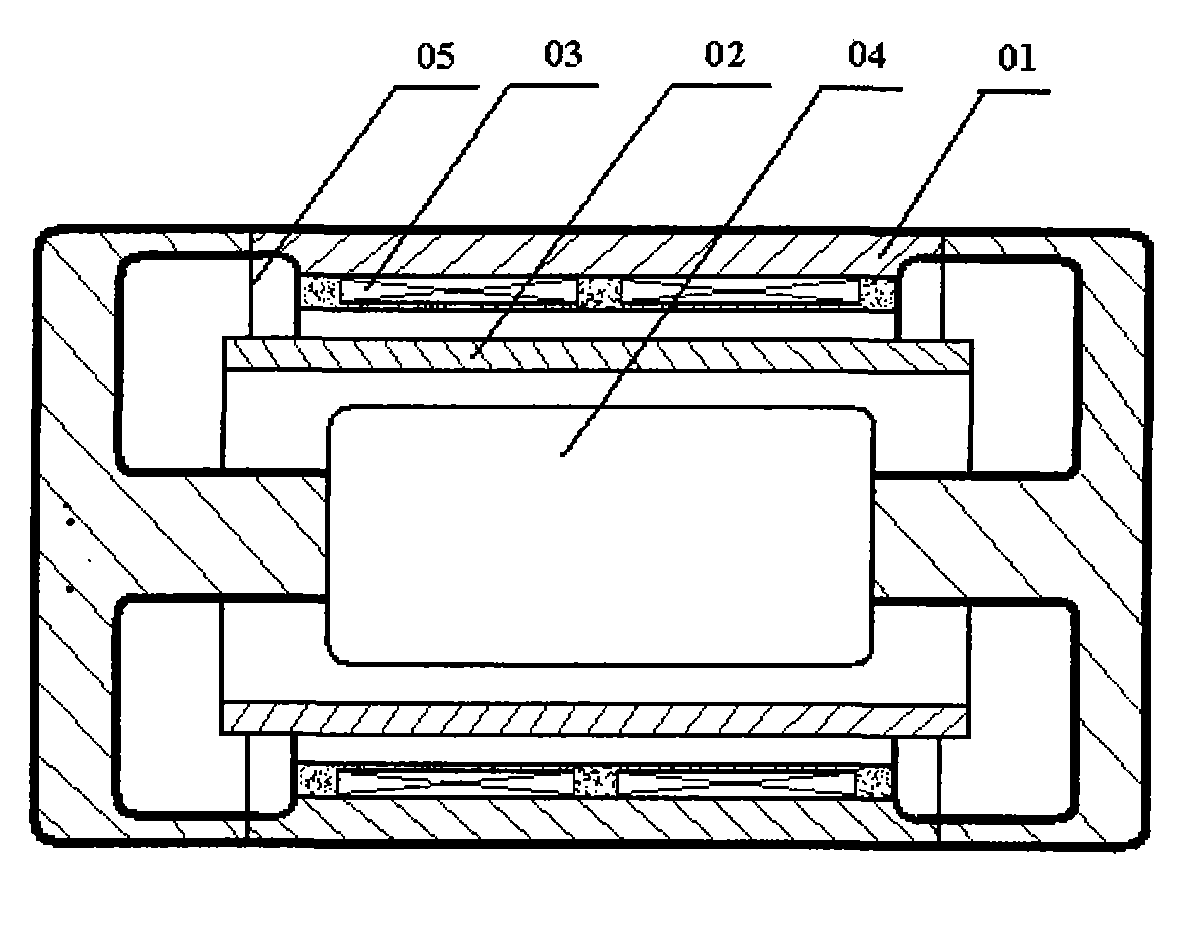

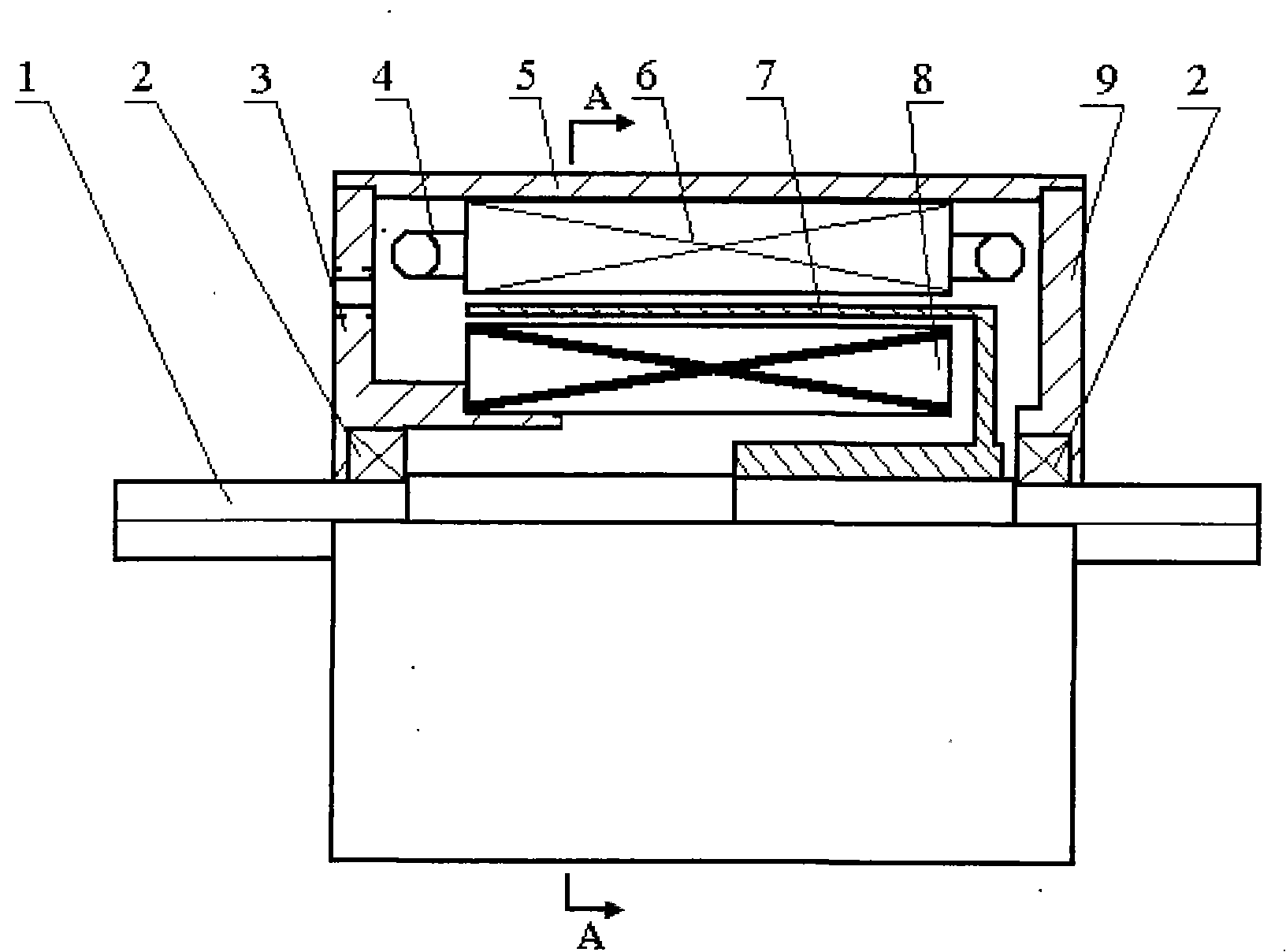

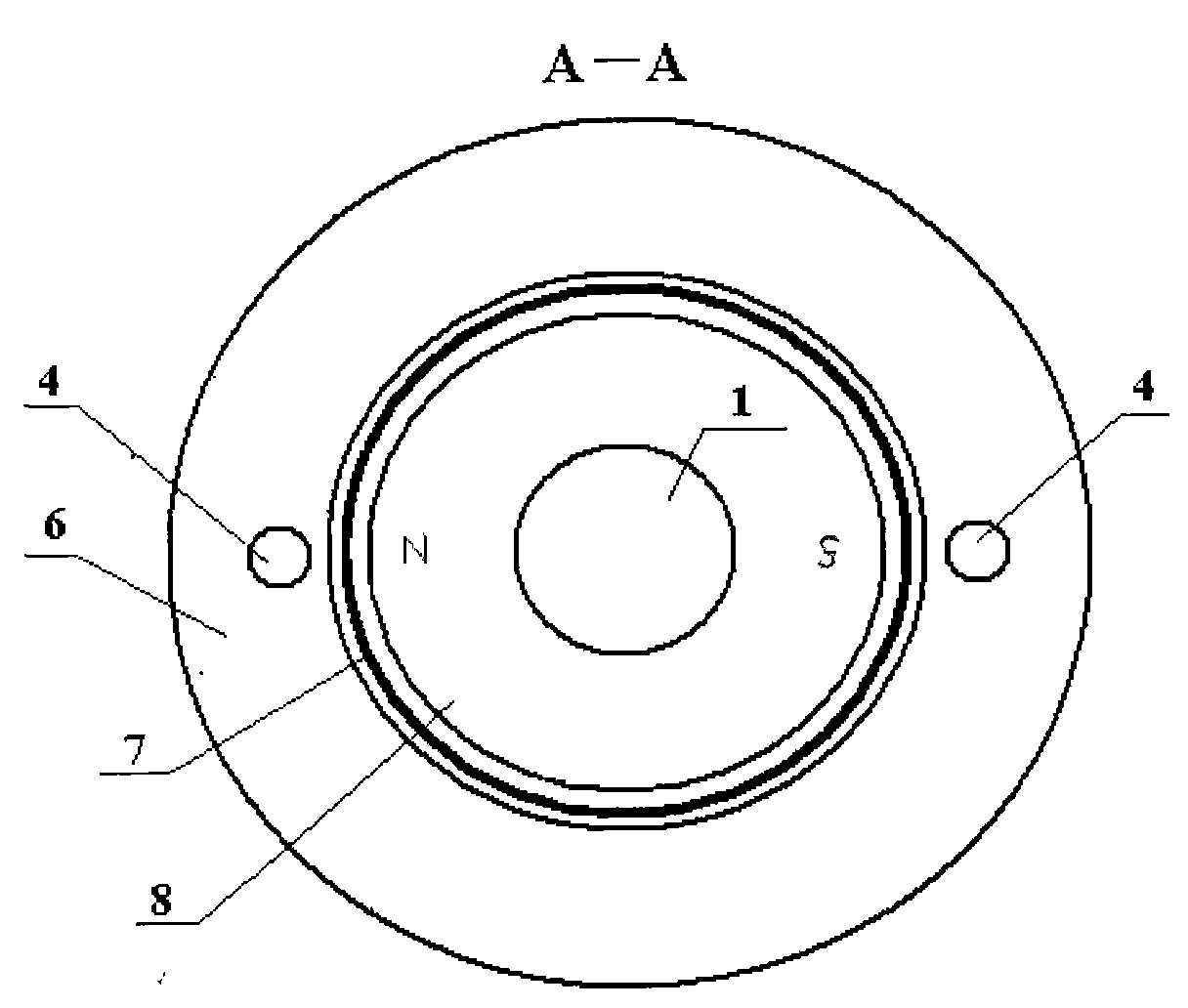

[0027] Embodiment 1: the structure of angular acceleration sensor is as figure 2 as shown, figure 2 The cross-sectional view of the A-A plane in the middle is as follows image 3 As shown, the excitation magnetic field is a permanent magnet structure: that is, the excitation magnetic field between the inner stator core 8 and the outer stator core 6 is a permanent magnet inner stator core composed of permanent magnet materials as the inner stator core 8 and the outer stator core 6. The excitation field formed by the exciter of the magnetic circuit. from image 3 It shows that the output winding 4 of the outer stator core is embedded in the winding slot of the outer stator core 6, and the axis of the output winding 4 of the outer stator core is perpendicular to the magnetic axis of the excitation field. The cup-shaped rotor winding 7 is located in the exciting magnetic field (air-gap magnetic field) between the inner and outer stator cores, and the outer stator core 6, cup-...

Embodiment 2

[0030] Embodiment 2: the structure of angular acceleration sensor is as figure 2 as shown, figure 2 The cross-sectional view of the A-A plane in the middle is as follows Figure 4 shown. The difference between embodiment 2 and embodiment 1 is that the excitation magnetic field is an electromagnetic structure. That is, the excitation magnetic field between the inner stator core 8 and the outer stator core 6 is powered by the outer stator core excitation winding 10 placed in the upper winding slot of the outer stator core 6 through a DC constant current source as the inner stator core 8 and the outer stator core 6 The excitation magnetic field formed by the excitation source of the magnetic circuit between them; Figure 4 As shown, the excitation winding 10 of the outer stator core and the output winding 4 of the outer stator core are embedded in the winding slot of the outer stator core 6, and the excitation winding 10 of the outer stator core excites the iron core through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com