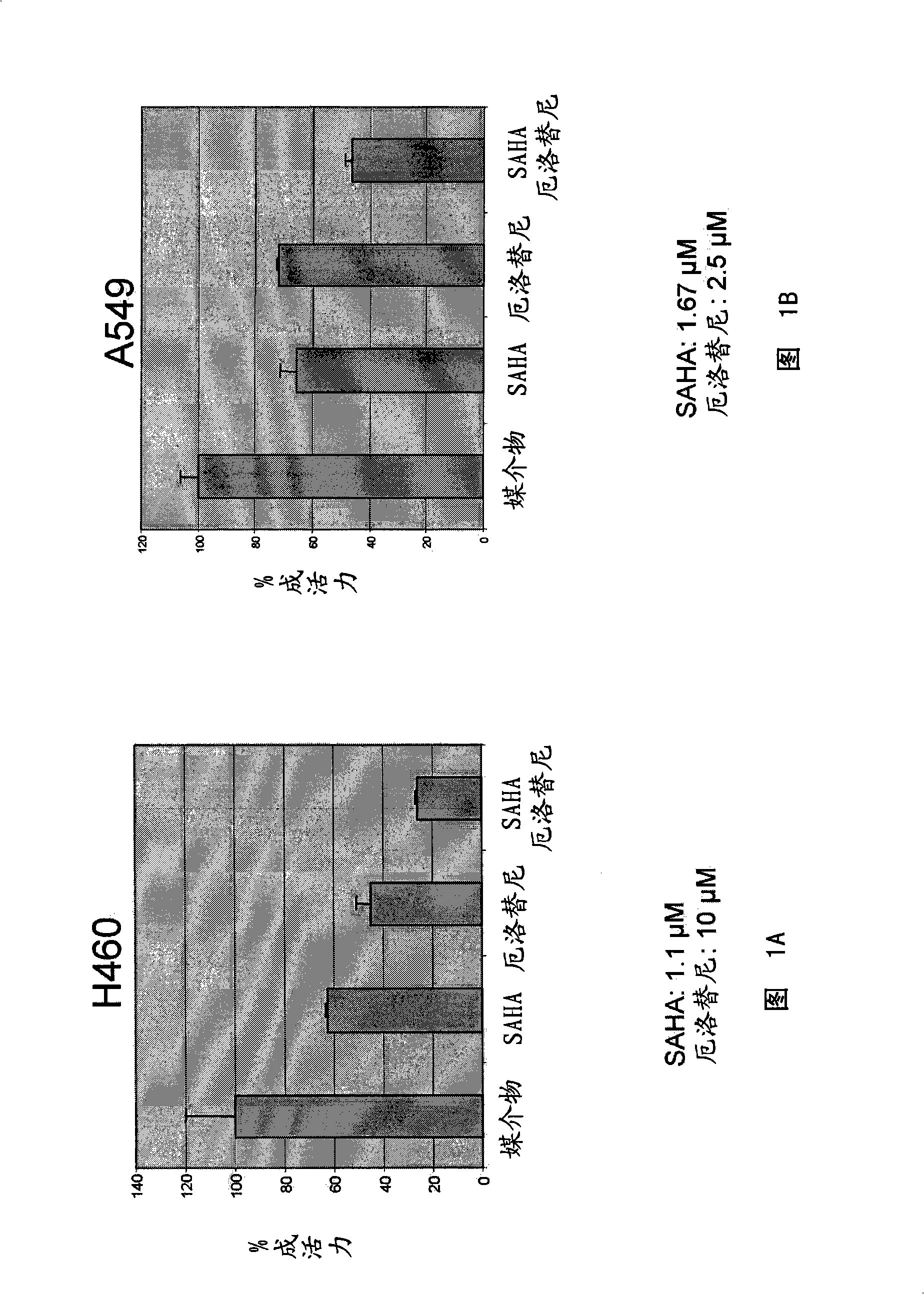

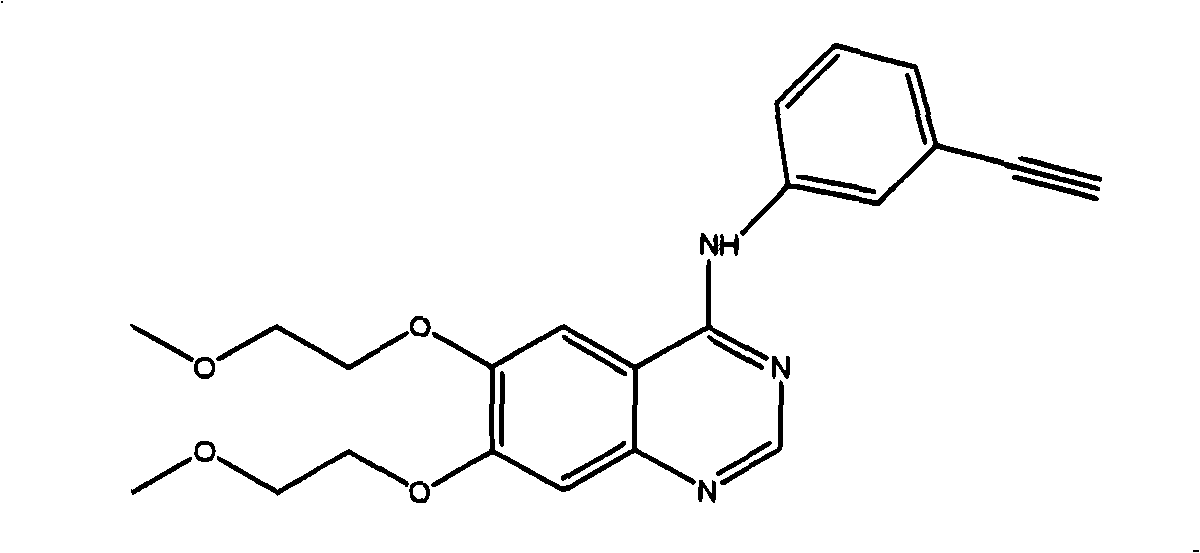

Method of using SAHA and Erlotinib for treating cancer

A technology of suberoylanilide hydroxamic acid and agent erlotinib, applied in the field of erlotinib, can solve the problem that DNA is difficult to enter transcriptional regulatory elements and structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

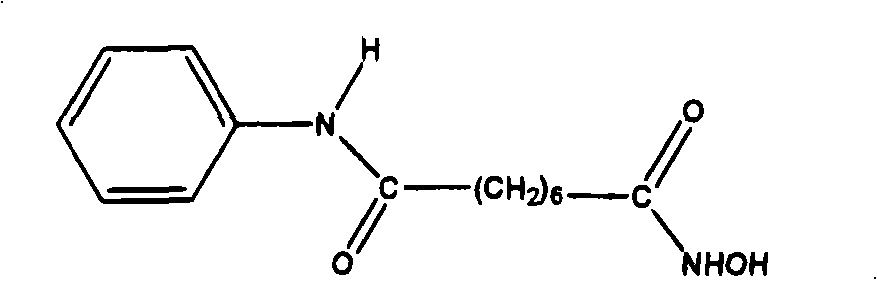

[0325] Embodiment 1: the synthesis of SAHA

[0326] SAHA can be synthesized as described below, or as described in US Patent No. 5,369,108 (which is incorporated herein by reference in its entirety), or by any other method.

[0327] Synthesis of SAHA

[0328] Step 1 - Synthesis of N-suberanilic acid

[0329]

[0330] In a 22L flask, add 3500g (20.09mol) of suberic acid, and heat and melt the acid. The temperature was raised to 175° C., and then 2040 g (21.92 mol) of aniline were added. The temperature was raised to 190° C. and maintained at this temperature for 20 minutes. The melt was poured into a Nalgene tank containing 4017 g of potassium hydroxide in 50 L of aqueous solution. The mixture was stirred for 20 minutes, then the melt was added. The reaction was repeated on the same scale and a second batch of the melt was poured into the same potassium hydroxide solution. After the mixture was stirred well, the stirrer was turned off and the mixture was allowed to...

Embodiment 2

[0347] Example 2: Production of Wet Milled Small Particles in 1:1 Ethanol / Water

[0348] SAHA polymorph I crystals were suspended in a 1:1 (by volume) EtOH / aqueous solution mixture at a slurry concentration of 50 mg / g to 150 mg / g (crystal / solvent mixture). Use IKA-WorksRotor-Stator high-shear homogenizer T50 type, wet-grind the slurry with a superfine powder blade at 20-30m / s, until the average particle size of SAHA is less than 50μm, and 95% is less than 100μm, while keeping the temperature at room temperature . The wet milled slurry was filtered and washed with a 1:1 EtOH / aq mixture at room temperature. The wet cake was then dried at 40°C. The final average particle size of the wet ground material was less than 50 μm as determined by the following Microtrac method.

[0349] The particle size was analyzed using a SRA-150 laser scattering particle size analyzer (manufactured by Microtrac Inc.). The analyzer is equipped with an ASVR (Automatic Small Volume Recirculator). ...

Embodiment 2A

[0350] Example 2A: Large scale production of wet milled small particles in 1:1 ethanol / water

[0351] Add 56.4kg of SAHA polymorph I crystals to 610kg (10.8kg solvent / kg SAHA) of 50% vol / vol 200 strength standard ethanol and water (50 / 50 EtOH / water) at 20-25°C in solution. The slurry (~700 L) was repeatedly cycled through the IKA Works wet milling unit with a micropowder generator until a steady state particle size distribution was reached. Conditions were: DR3-6, 23 m / s rotor tip speed, 30-35 Lpm, 3 gens, ~96 cycles (one cycle is a batch of volume through one gen), ~12 hours.

[0352]

[0353] The wet cake was filtered, washed 2X with water (6 kg / kg total, ~340 kg), dried under vacuum at 40-45°C. The dry cake was then sieved (595 μm sieve) and packaged as Refined API.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com