Construction method using soil curing material to build water storage facilities

A soil solidification and construction method technology, applied in water conservancy projects, construction, marine engineering and other directions, can solve the problems of high cost, difficult to obtain materials, poor durability, etc., achieve simple construction, high strength and anti-seepage performance, and reduce construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

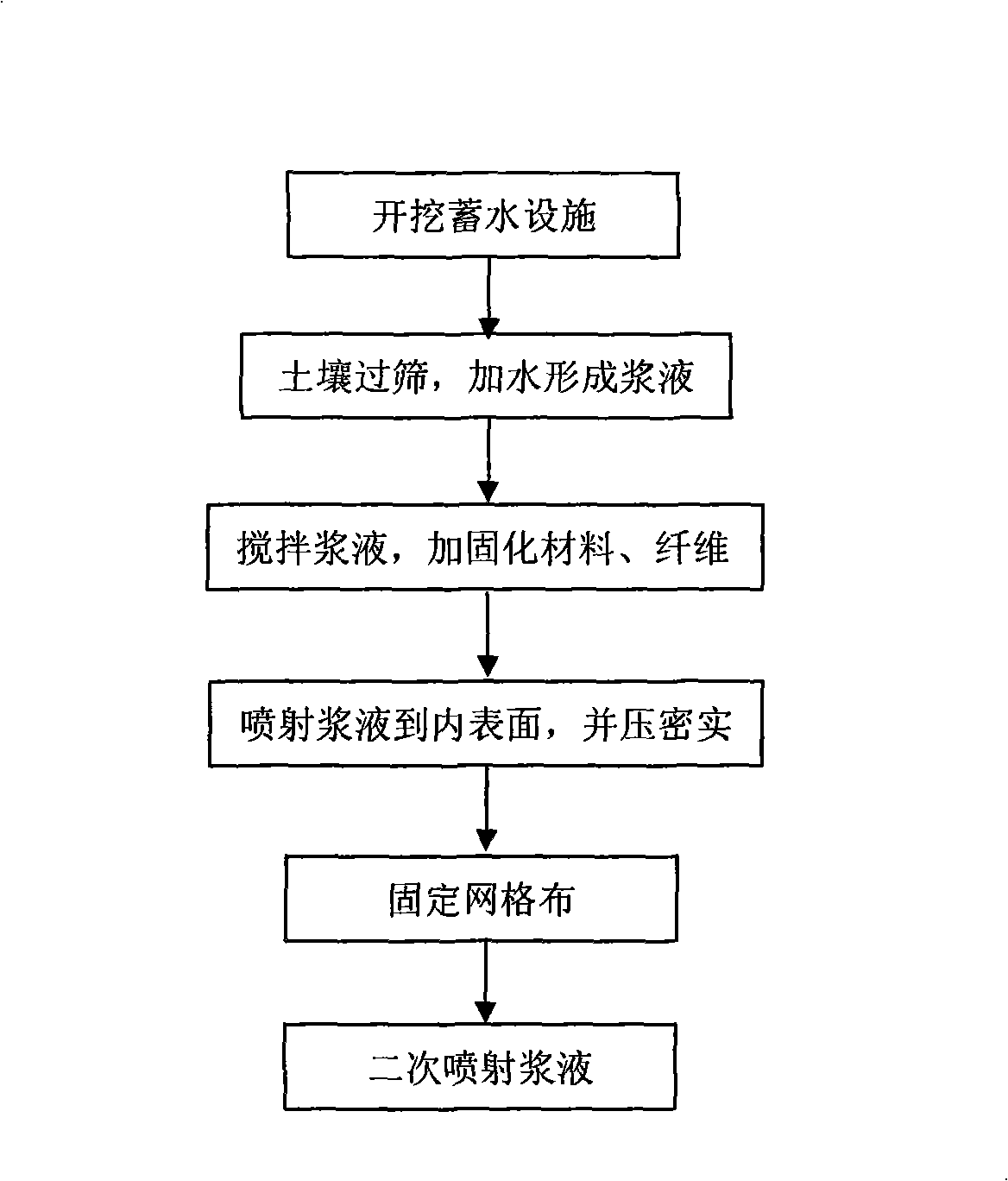

[0019] The construction method of the present invention for building water storage facilities using soil-solidified materials includes soil-solidified materials, soil, water, fibers, mesh cloth, etc., and the main equipment is a mixer, a cement mortar sprayer, and a pressurized dense stick.

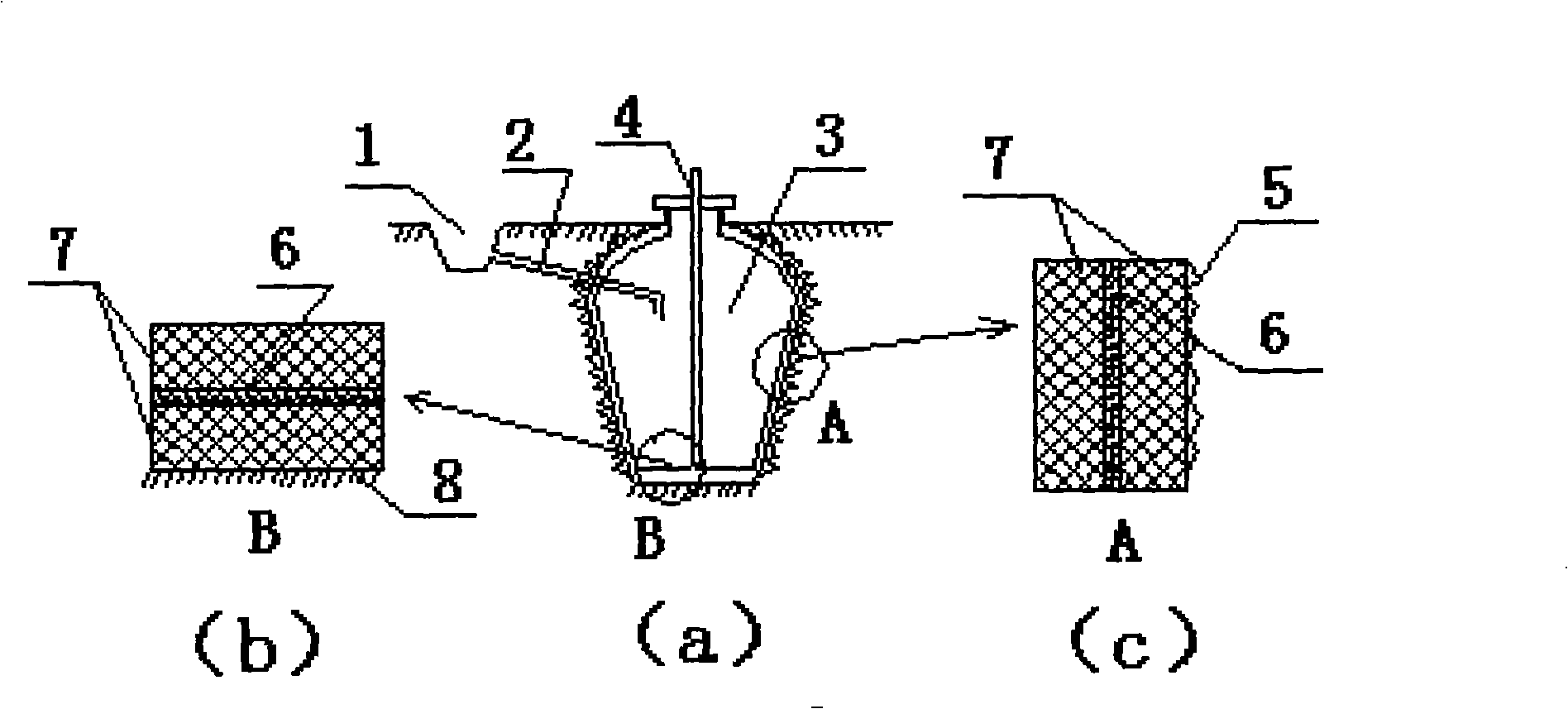

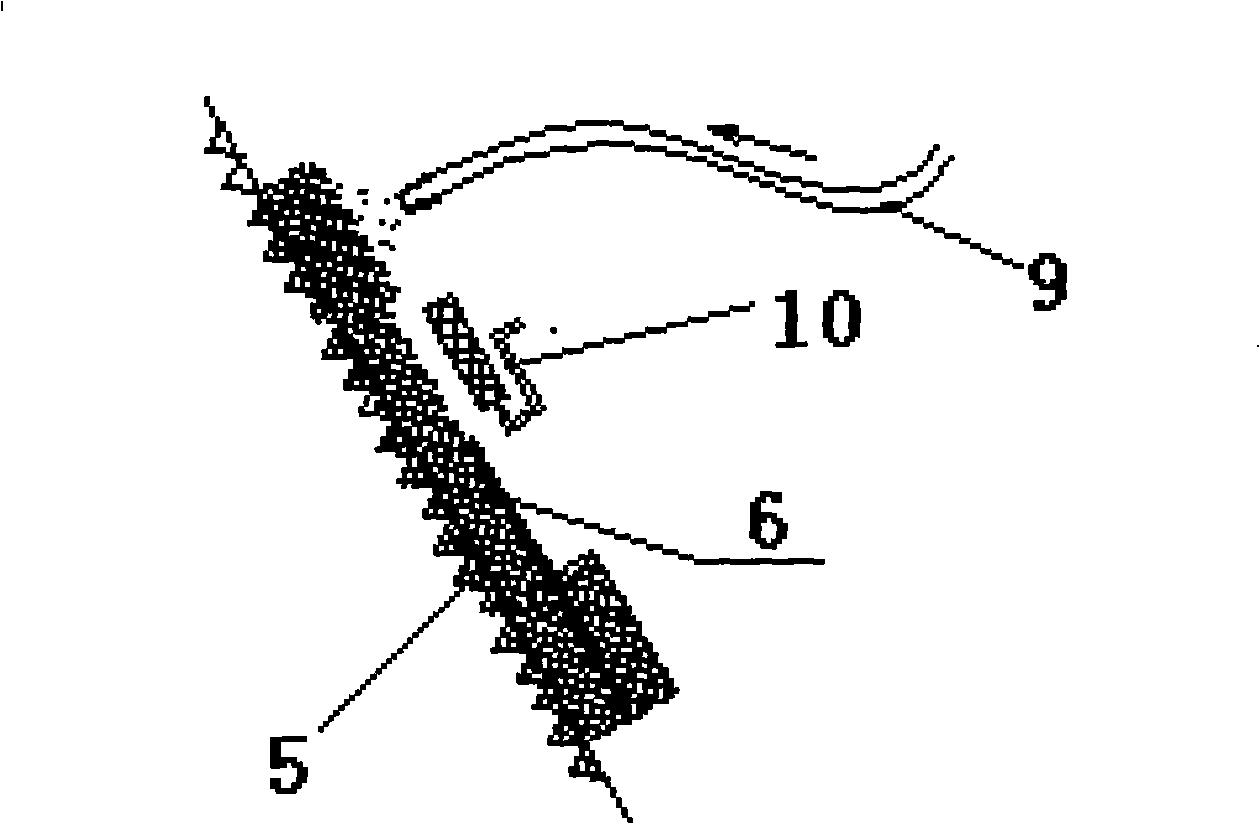

[0020] See attached picture, follow figure 1 Excavate the sedimentation tank 1 below the ground, make the water inlet pipe 2, the water cellar 3, and the inner surface of the water cellar 3 to make the rough surface 5, and the middle is provided with the water lifting pipe 4 (figure a), and A in the figure c is that of the figure a The enlarged pattern of the side wall of the water cellar 3, B among the figure (b) is the enlarged pattern of the bottom of the cellar of the cellar 3 of Fig. a, the side wall of the water cellar 3 is sprayed with the soil solidified soil layer 7 with mesh cloth 6 , the bottom 8 of the cellar 3 of the water cellar 3 is also sprayed with the soil solidified soi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com