Support arm, cylindrical-parabolic solar collector support and method of producing said arm

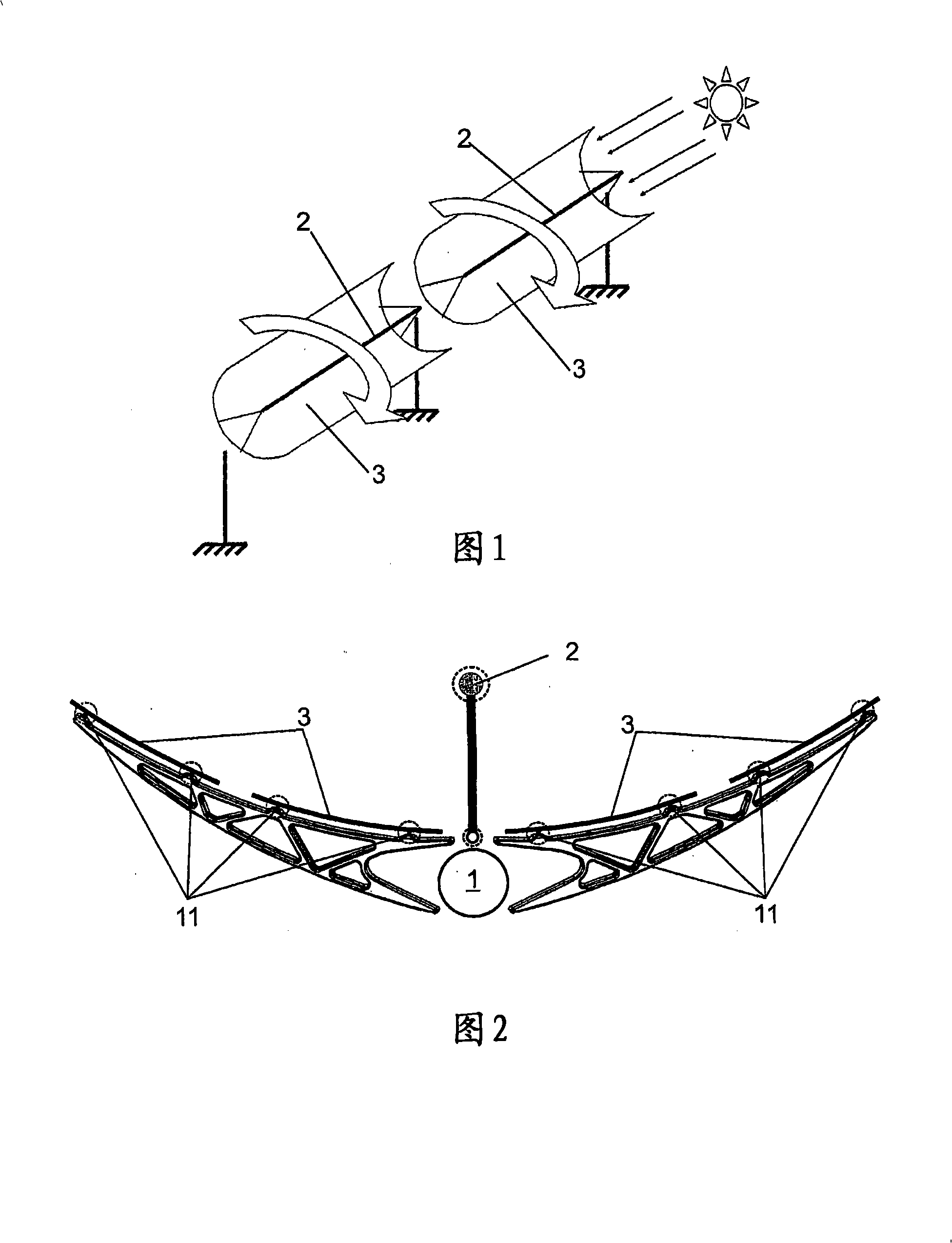

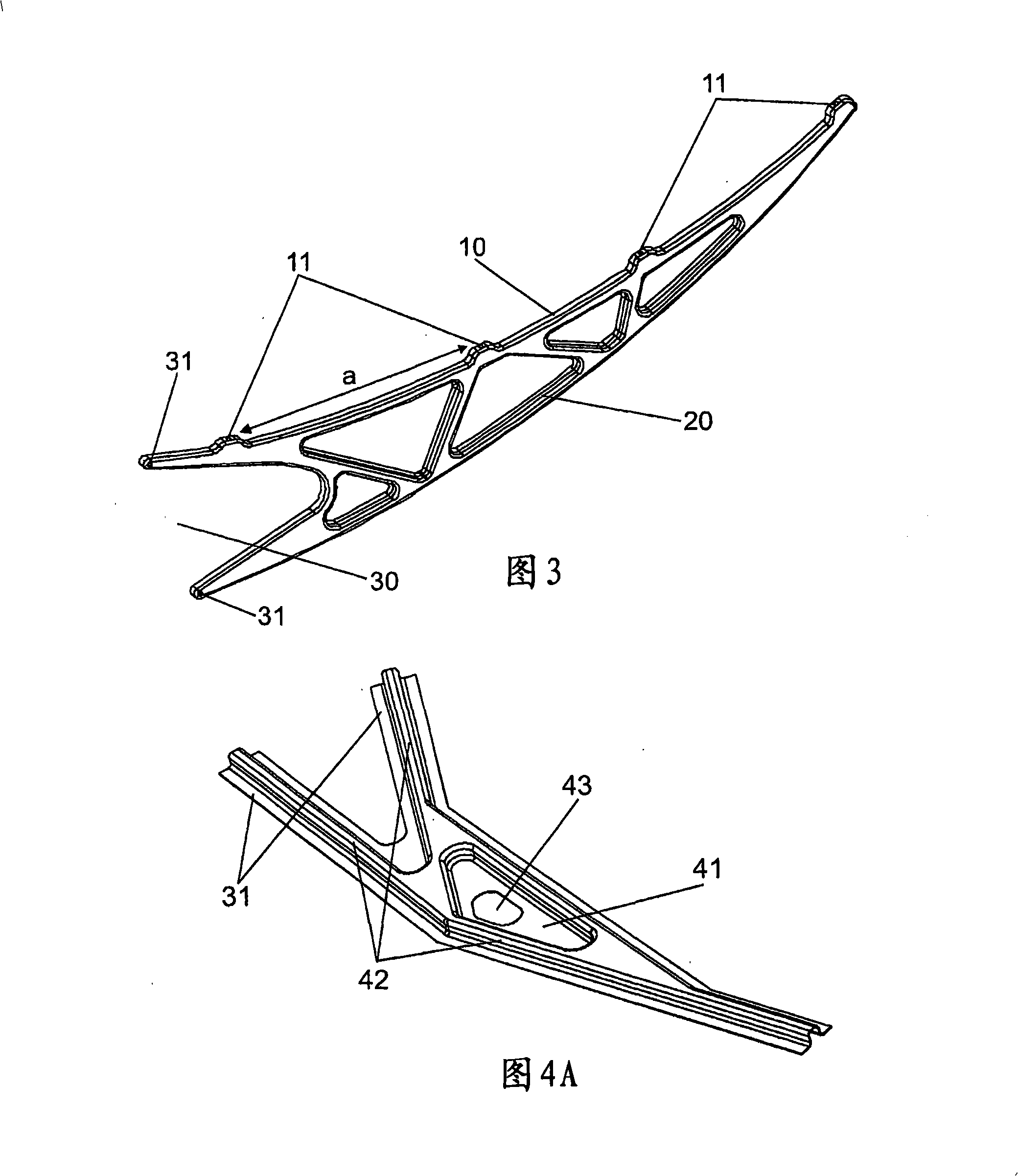

一种太阳能收集器、抛物面的技术,应用在太阳能集热器、太阳能集热器的固定底座/支架、移动/定向太阳能集热器等方向,达到高再现性、低成本、易于自动化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

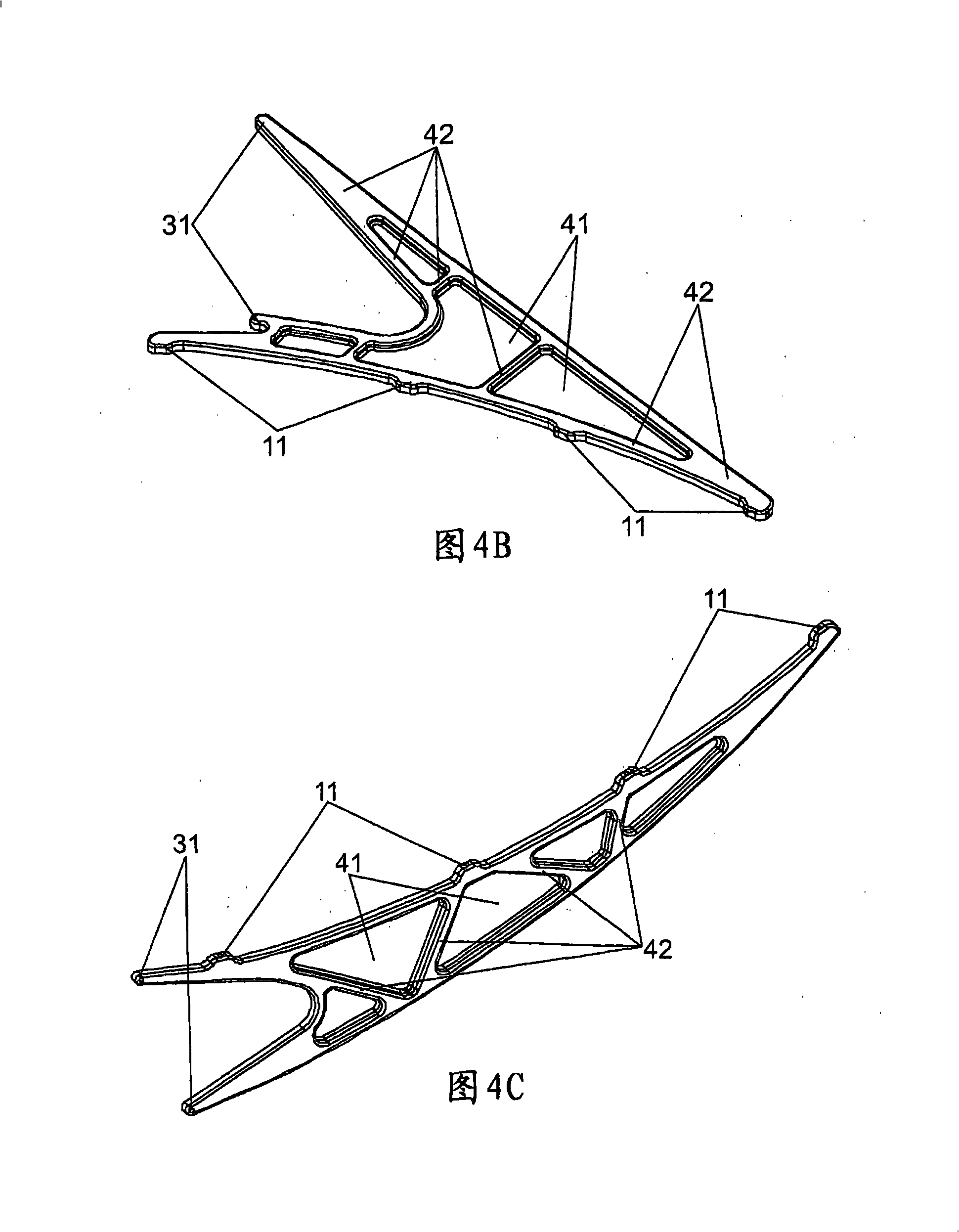

[0073] More than 200,000 arms are required in a commercial solar power plant. Such a large number of necessary units necessitates an extremely simple manufacturing process for these elements in order to reduce costs without compromising their ability to absorb loads, while providing adequate rigidity and precision.

[0074] For this purpose, the arm coupled to the central body 1 of the collector in the form of a support along a direction substantially perpendicular to the focal line 2 of said collector has a wedge-shaped shape with a first side 10 having a support reflector Support means 11 of mirror 3 ; second side 20 ; and third side 30 with support means 31 for said arms to be supported by central body 1 . In the present invention, the support arm is formed from at least one press-formed plate to obtain a resistant structure, providing rigidity and load-bearing capacity by means of a plurality of ribs 42 forming a grid between said ribs 42. There are a plurality of laminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com