Ultra-high pressure automatic oiling device

An automatic oil injection and ultra-high pressure technology, which is applied in fluid pressure converters, metal processing, metal processing equipment, etc., can solve the problems of reduced wheel and axle performance indicators, inability to adapt to high-speed trains, unfavorable wheel maintenance, etc., to improve product quality and stability performance, reduced scrap rate, and reduced power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The present invention is further described in conjunction with accompanying drawing:

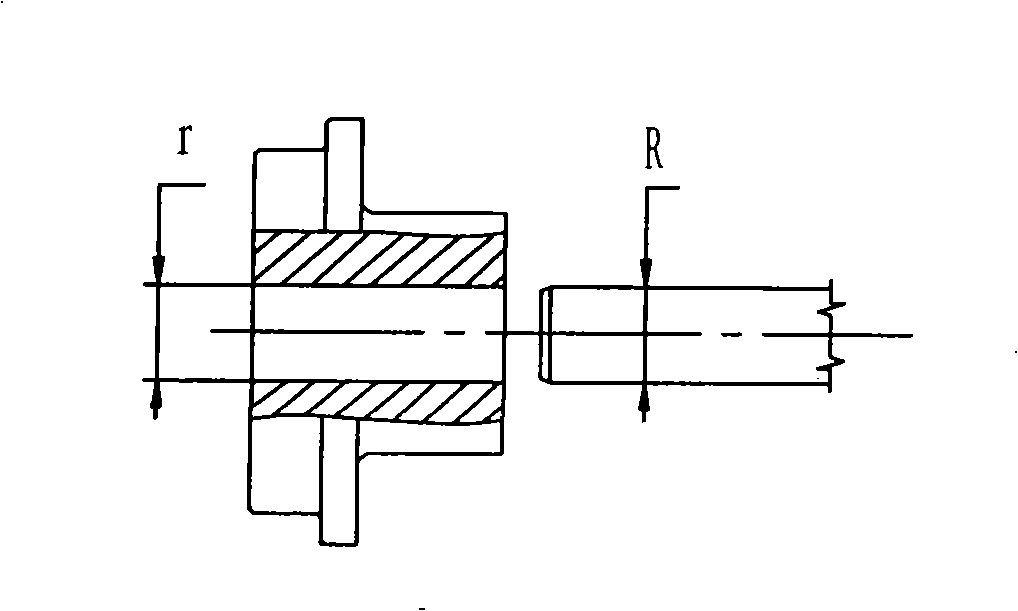

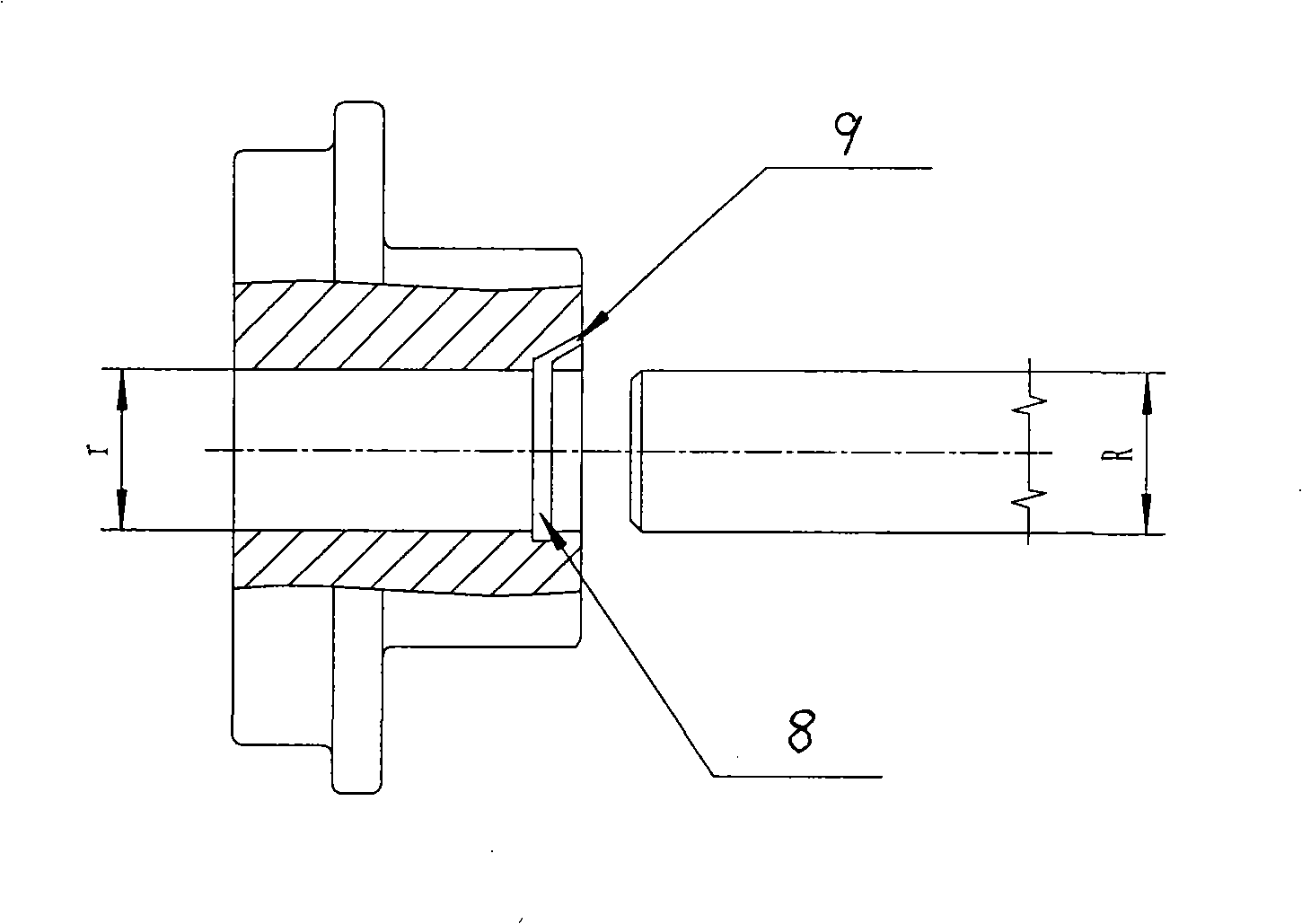

[0027] As shown in Figure 2, 8 is the oil injection groove, and 9 is the oil injection hole; firstly, an oil injection groove is opened on the edge of the wheel hub, and an oil injection hole is drilled, and ultra-high pressure hydraulic oil is injected during the press-fitting process to expand the wheel hub, and in the wheel, A layer of oil film is formed on the joint surface of the shaft, and the rear wheel is pressed into the shaft without wear. After unloading, the hub is restored to achieve no wear and tear. The same is true when the wheel is withdrawn.

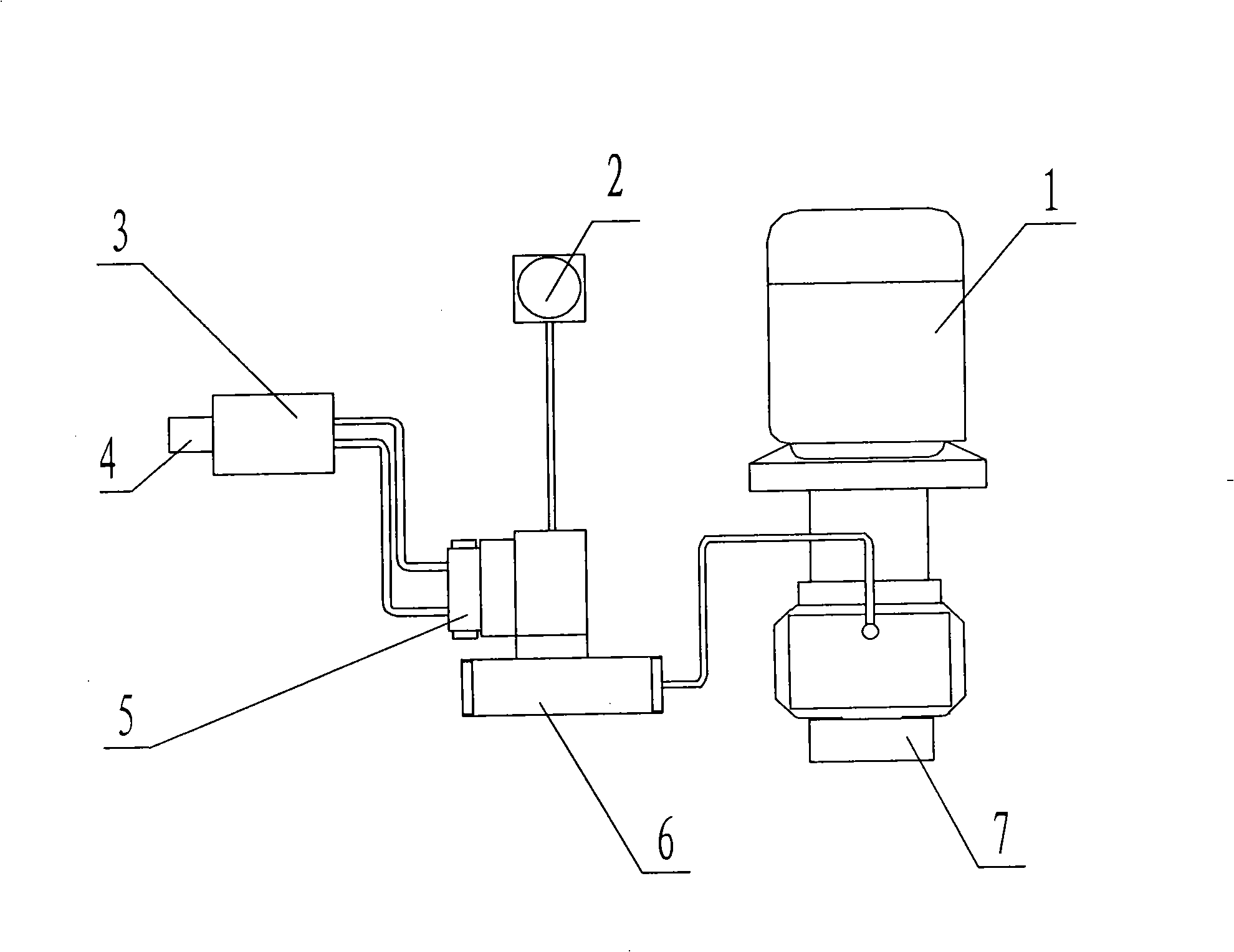

[0028] The working principle is shown in Figure 3:

[0029] 1 is a motor, 2 is an oil return filter, 3 is a supercharger, 4 is an oil outlet, 5 is an electromagnetic reversing valve, 6 is an electromagnetic overflow valve, and 7 is a gear pump.

[0030] The motor drives the gear pump to rotate to generate pressure oil. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com