Gan substrate, and epitaxial substrate and semiconductor light-emitting device employing the substrate

An epitaxial substrate and substrate technology, which is applied in the manufacturing of semiconductor devices, semiconductor lasers, semiconductor/solid-state devices, etc., can solve the problems of lower emission efficiency, lower device emission efficiency, etc., and achieve the effect of improving emission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

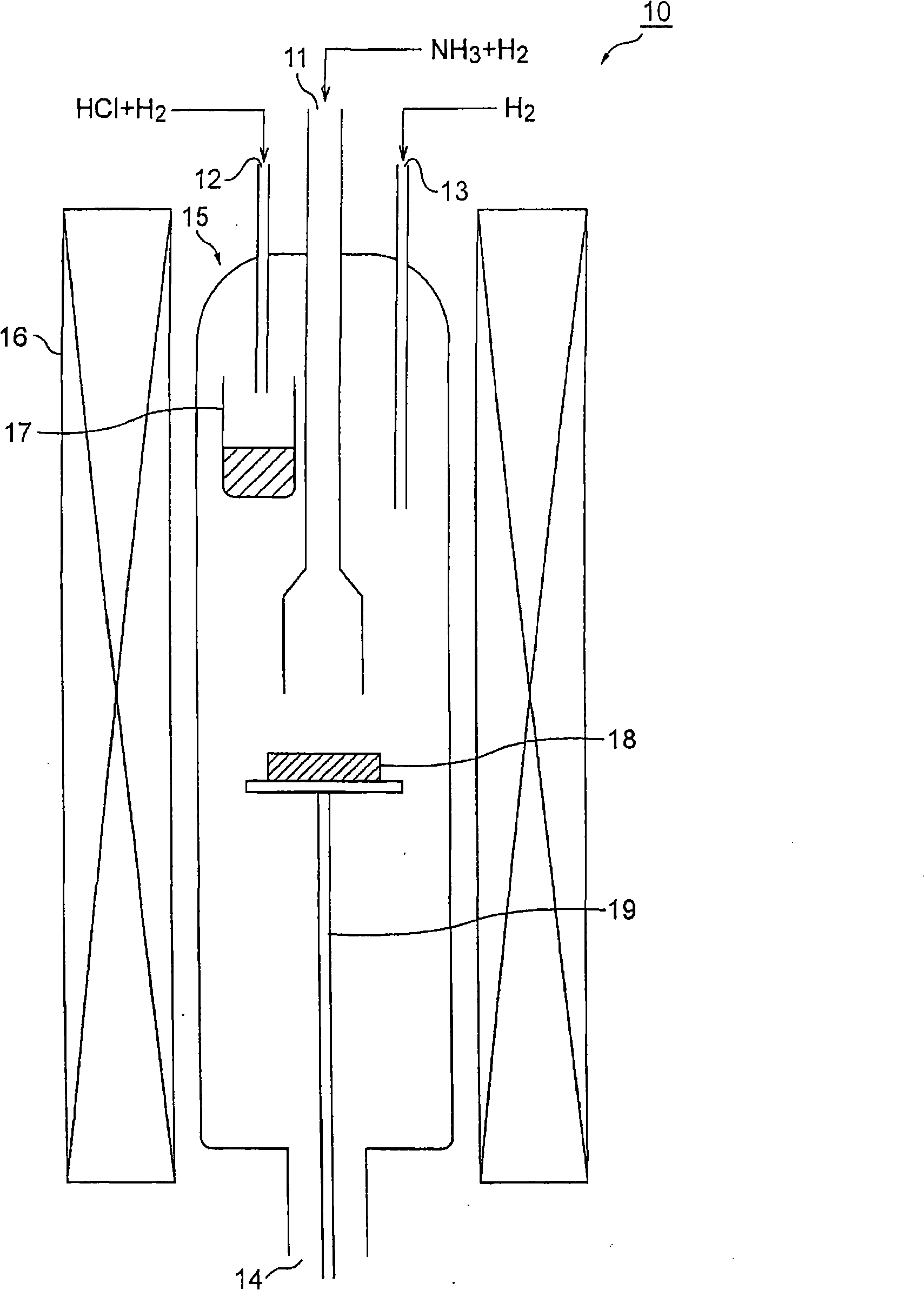

Method used

Image

Examples

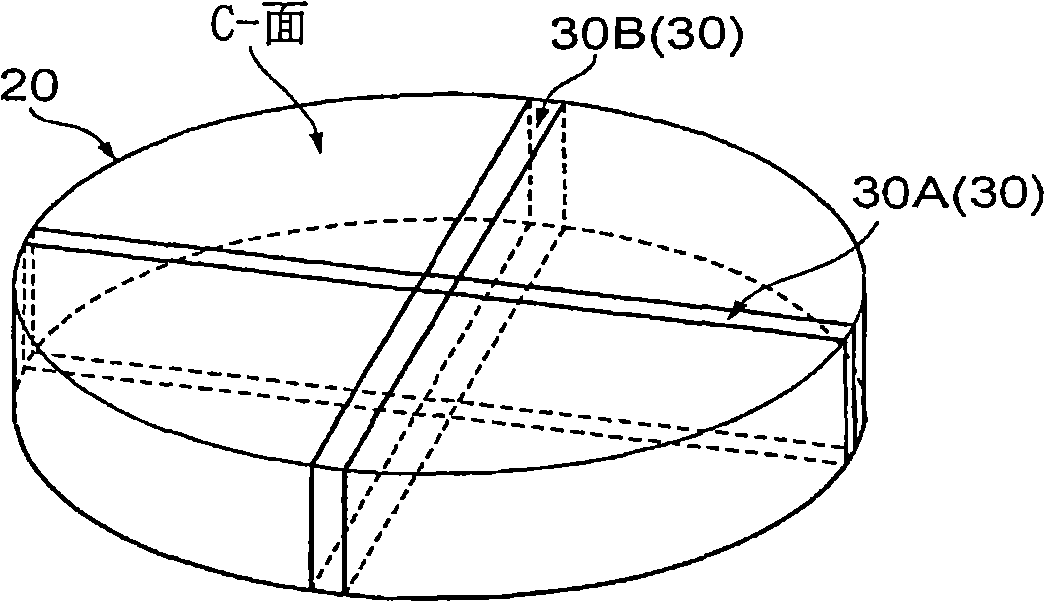

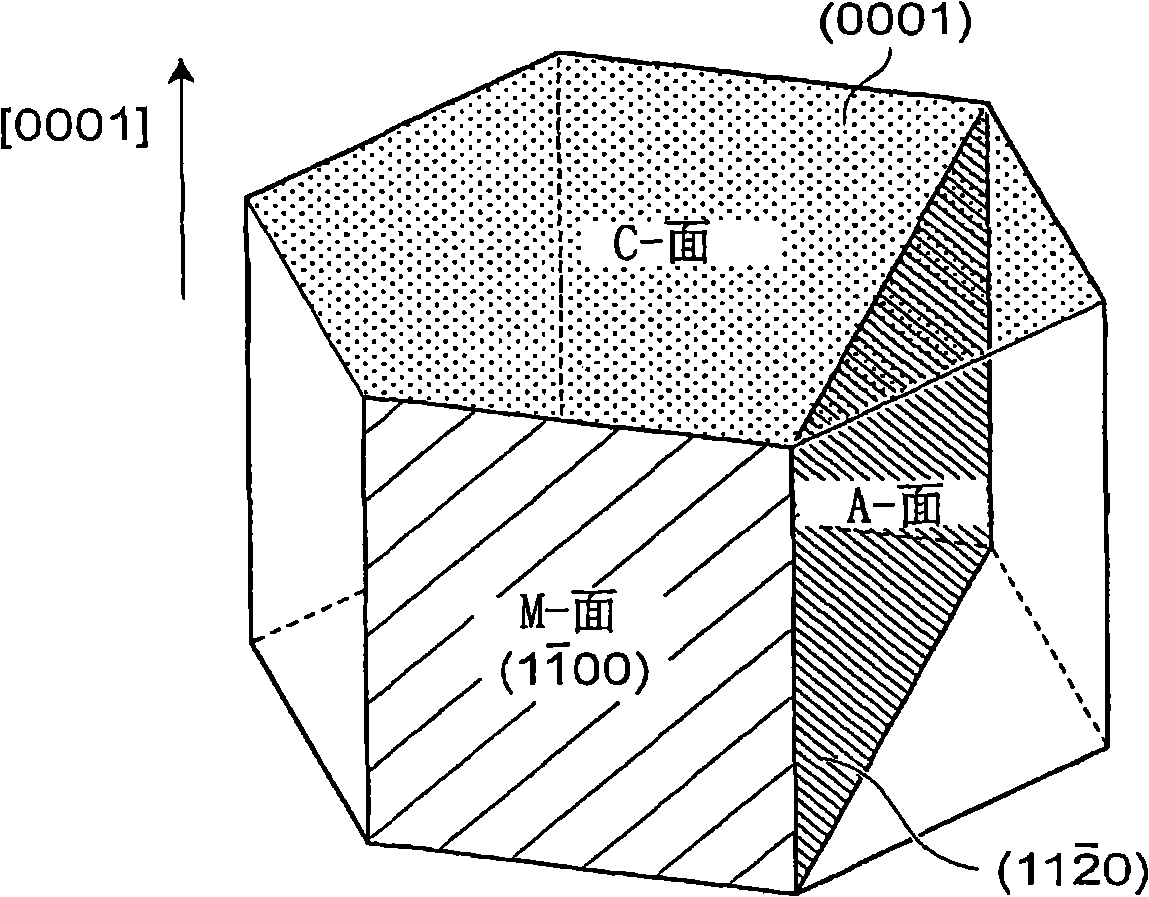

Embodiment 1

[0039] First, GaN substrate samples 1 to 14 were prepared according to the same process as the above-mentioned embodiment mode, which were the same or equivalent to the above-mentioned GaN substrate 30A-GaN substrate 5mm×20mm, the difference is that, as shown in the following Table I, Off-axis angle relative to the m-plane. In particular, among samples 1-14, the mis-orientation axis of samples 1-7 was the direction, and among samples 8-14, the mis-orientation axis was the direction. It should be noted that the crystal plane orientation (off-axis angle) of the GaN substrate is characterized by X-ray diffraction, and the measurement accuracy of the off-axis angle is ±0.01 degrees.

[0040] Table I

[0041] off-axis angle

0.00

0.03

0.1

0.3

0.5

1.0

2.0

direction

sample 1

sample 2

sample 3

Sample 4

Sample 5

Sample 6

Sample 7

direction

Sample 8

Sample 9

sample 10

Sample ...

Embodiment 2

[0056] In a manner similar to Example 1, GaN substrate samples 15 to 28 were prepared according to the same procedure as the previously explained embodiment mode, which were the same or equivalent to the above-mentioned GaN substrate 30B-GaN substrate 5mm×20mm, as follows Table IV, the difference is the off-axis angle relative to the a-plane. In particular, among samples 15-28, the mis-orientation axis of samples 15-21 was , and among samples 22-28, the mis-orientation axis was the direction. It should be noted that the crystal plane orientation (off-axis angle) of the GaN substrate is characterized by X-ray diffraction, and the off-axis angle measurement accuracy is ±0.01 degrees.

[0057] Table IV

[0058] off-axis angle

0.00

0.03

0.1

0.3

0.5

1.0

2.0

direction

Sample 15

Sample 16

Sample 17

sample 18

sample 19

Sample 20

sample 21

direction

Sample 22

Sample 23

Sample 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com