Vacuum sublimation purification method and device of organic material

A technology of organic materials and purification methods, which is applied in the field of vacuum sublimation purification and devices for organic materials, can solve the problems of poor purification methods, impractical purification of organic matter, and low sublimation point of organic matter, and achieves simple structure, easy operation, and improved The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

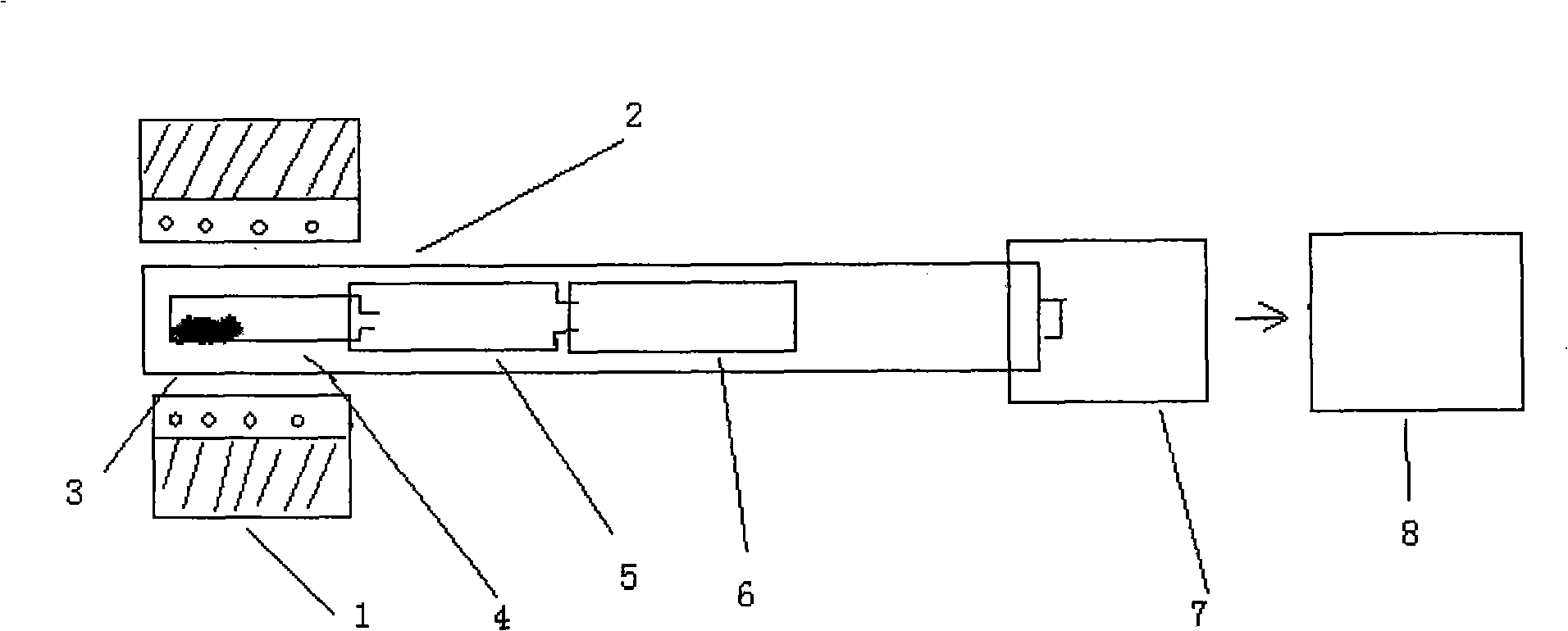

[0018] Referring to Figure 1, the vacuum sublimation purification device mainly includes a glass container with a deposition chamber, a resistance furnace, a vacuum pumping system, and a heating temperature control system.

[0019] Taking copper phthalocyanine as an example, the specific purification process is as follows:

[0020] The first sublimation: Place copper phthalocyanine, an organic material with low purity (about 93%) bought from the market, in the first section of the glass tube, move the temperature zone of the heating furnace to the area of the first section of the glass tube, and connect to the vacuum system. Vacuum down to 4×10 -3 After Pa, start heating, control the temperature at 230°C, sublimation starts, its material condenses in the second glass tube, its color is purple, and some impurities remain in the first glass tube. After about 30 minutes, the rest of the material turned dark purple, and the heating and vacuuming were stopped, and the first subl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap