Imitated titanium processing process for magnesium alloy

A treatment process, magnesium alloy technology, applied in metal material coating process, pretreatment surface, superimposed layer plating, etc., can solve the problems of coating wear, loss of magnesium alloy metal texture and touch, etc., to achieve anti-corrosion problems, improved resistance to abrasion and scratches, metallic texture and tactile retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

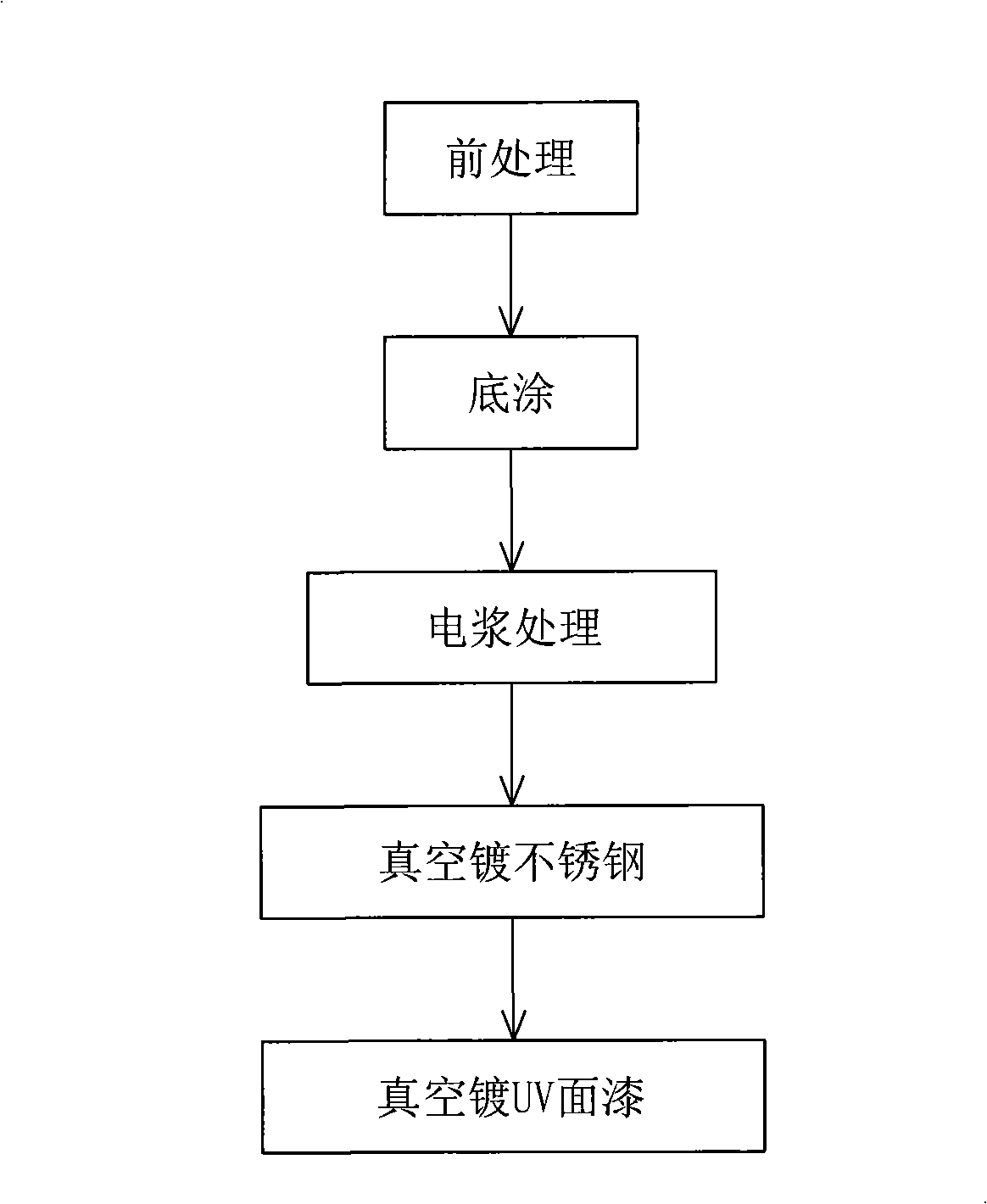

[0013] Take a sample magnesium alloy part, and the steps of its imitation titanium treatment are as follows:

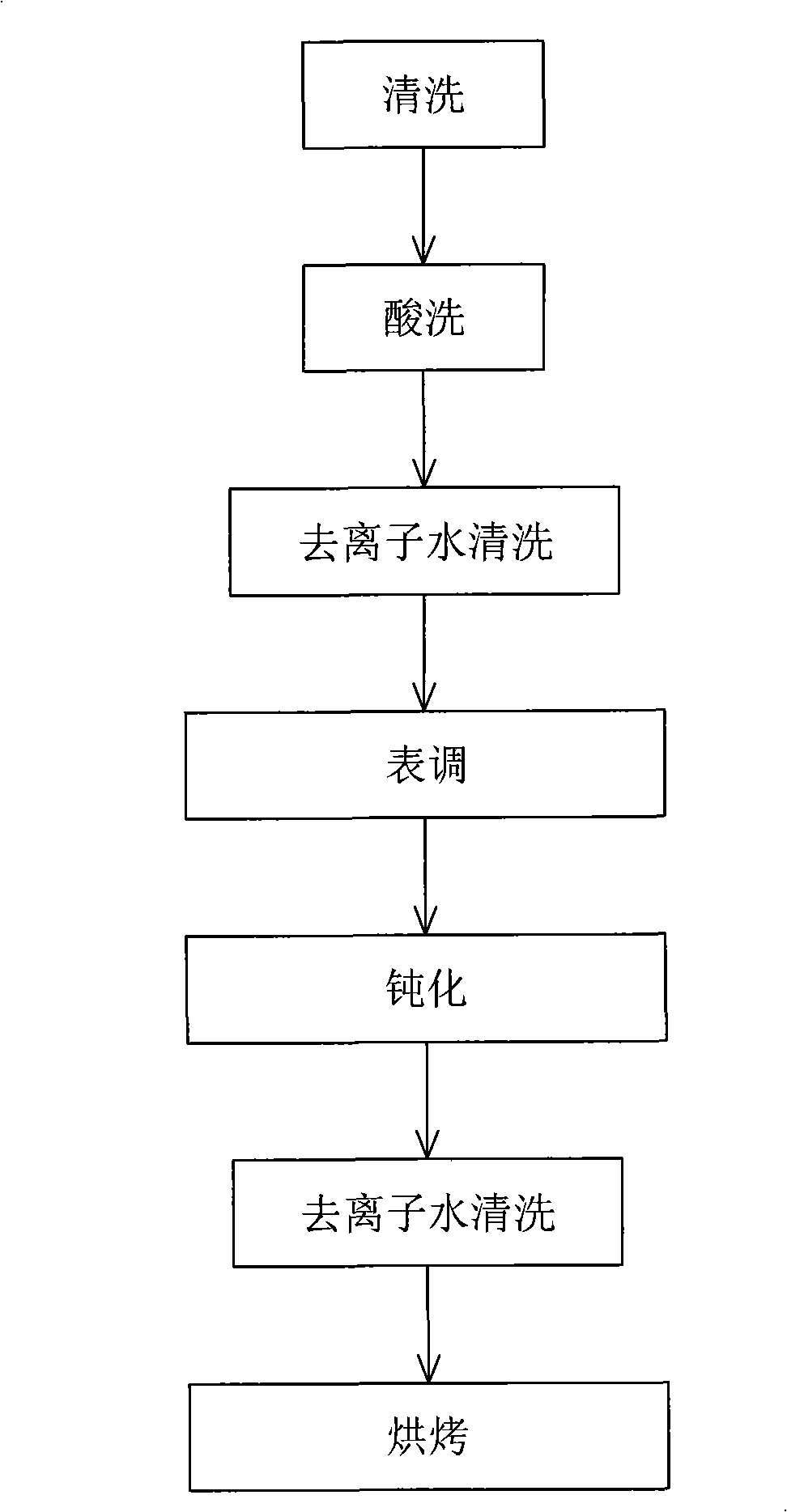

[0014] As shown in Figure 2, first the magnesium alloy surface is pretreated to clean the magnesium alloy surface, the previous treatment steps:

[0015] The first step is cleaning; pickling is used for decontamination, which is treated with a mixed solution of nitric acid and 1g / L sulfuric acid with a mass fraction of 8%; in order to remove the residual acid solution from the previous step, the surface of the magnesium alloy is cleaned with deionized water Then use alkaline solution to adjust the surface to neutralize the acidic solution remaining on the surface of the magnesium alloy due to pickling; use a chromium-free passivator to passivate the magnesium alloy after surface adjustment, and form a chemical film to prevent surface oxidation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com