Semiconductor device, leadframe and structure for mounting semiconductor device

A semiconductor and lead frame technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of no confrontation, etc., and achieve the effects of improving performance characteristics, reducing crosstalk interference, and narrowing the spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example --

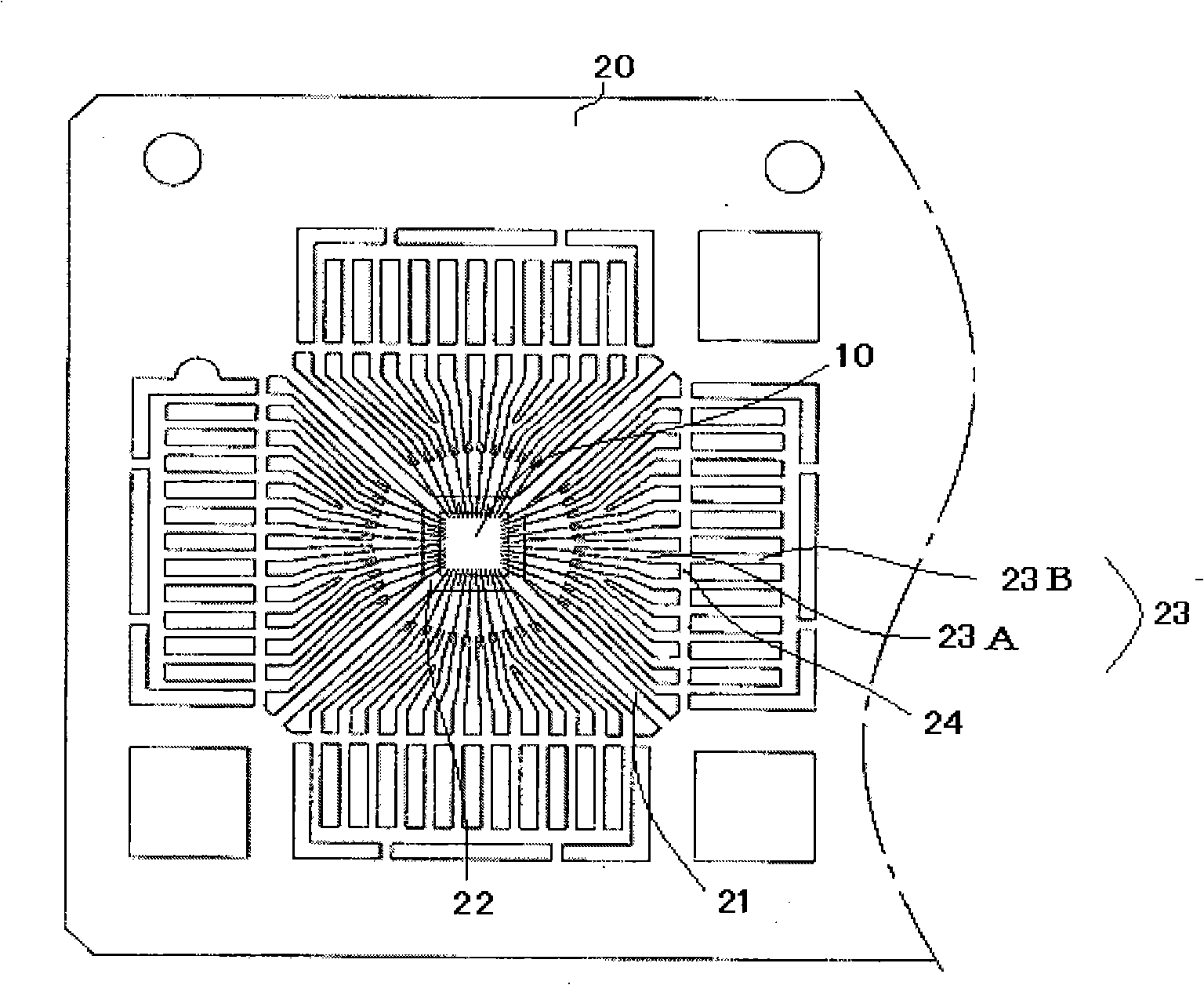

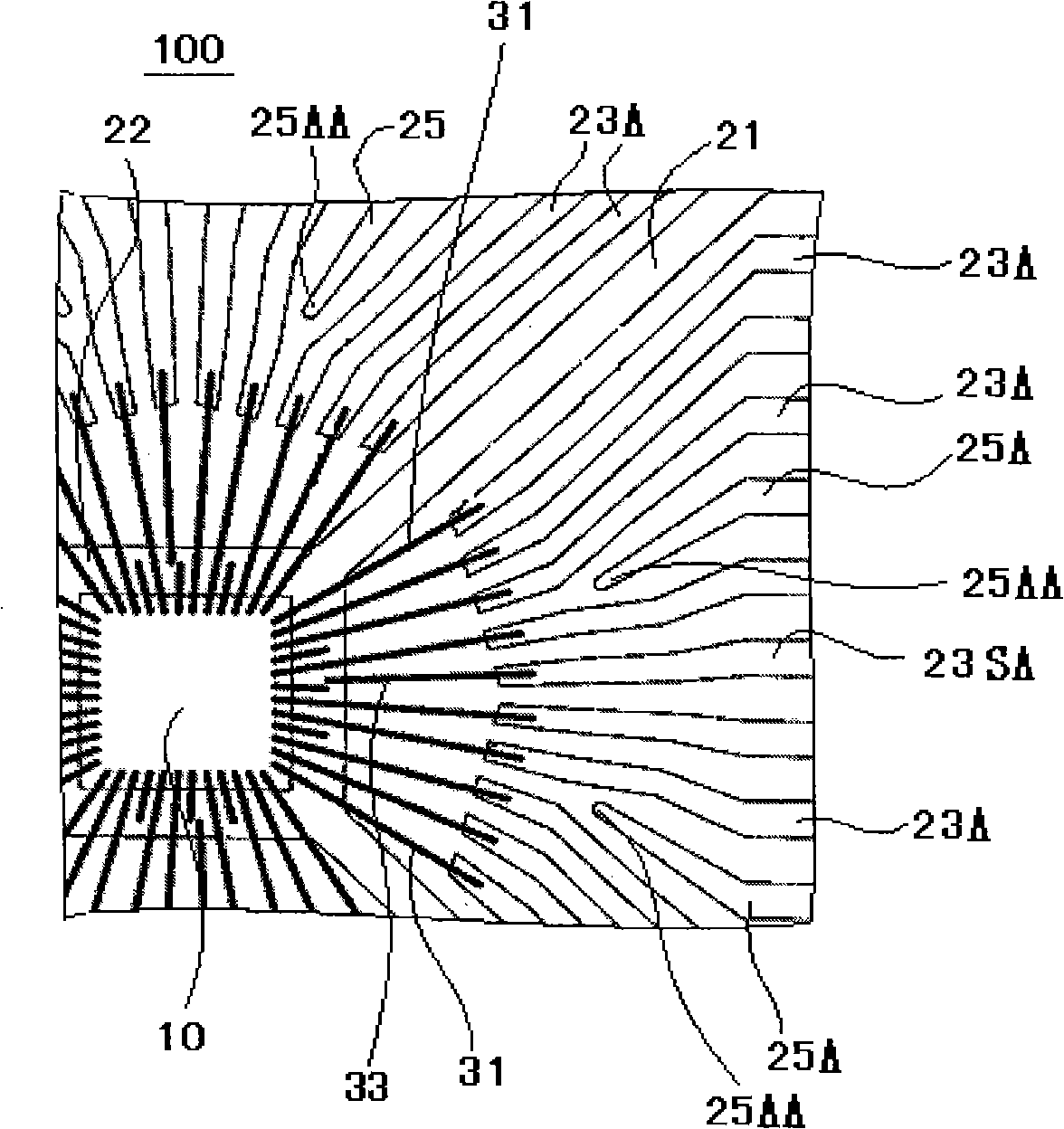

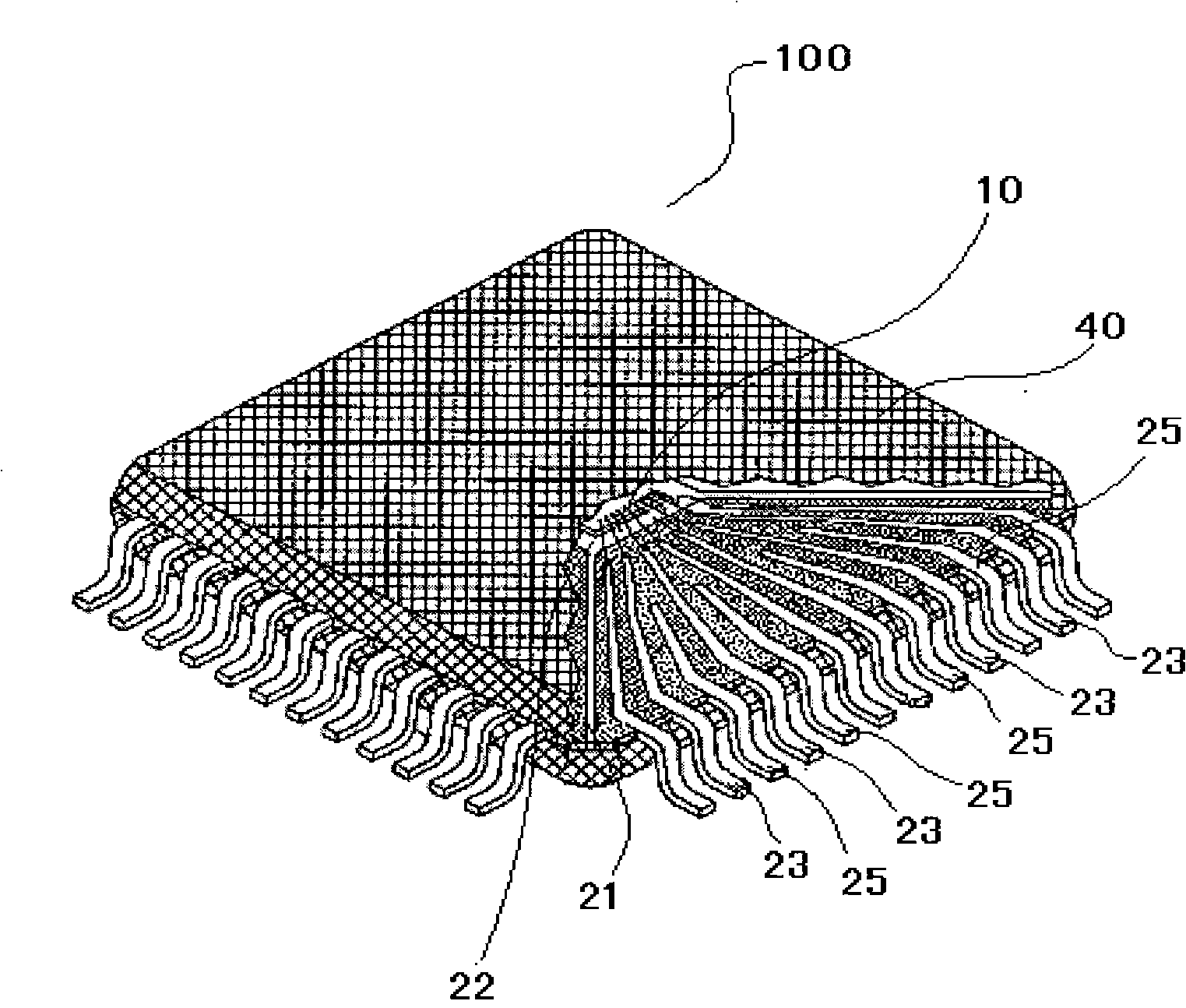

[0045] refer to Figure 1A , Figure 1B and figure 2 A first example of a semiconductor device according to the present invention, the semiconductor device 100, is described.

[0046] Figure 1A A lead frame of the semiconductor device 100 and an arrangement of semiconductor elements mounted on the lead frame are shown. Figure 1B show Figure 1A The main part of the magnification.

[0047] In this example, the semiconductor element 10 is mounted and attached to the rectangular die stage 22 of the lead frame 20 , and the four corners of the die stage 22 are supported by the die stage rods 21 . Electrode terminals of the semiconductor element 10 are connected to the leads 23 of the lead frame 20 through bonding wires 31 , and optionally connected to the die stage 22 .

[0048] A plurality of leads 23 (first leads) are arranged on substantially the same plane around the die stage 22 . Each lead 23 has a portion called an inner lead 23A and an outer lead 23B through a tie...

example 2

[0073] refer to Figure 3A and FIG. 3B depict a second example of a semiconductor device according to the present invention, a semiconductor device 200 .

[0074] Figure 3A A lead frame of the semiconductor device 200 is shown, and an arrangement of semiconductor elements mounted on the lead frame is shown. Figure 3B shows the Figure 3A The main part of the magnification.

[0075] Note that the same reference numerals are used for the Figure 1A , Figure 1B and figure 2 The components corresponding to the components of the semiconductor device 100 shown in FIG.

no. 1 example

[0076] Similar to the first example, the semiconductor element 10 is mounted and attached to the rectangular die stage 22 of the lead frame 20 , and the four corners of the die stage 22 are supported by the die stage rods 21 . Electrode terminals of the semiconductor element 10 are connected to the leads 23 of the lead frame 20 through bonding wires 31 , and optionally connected to the die stage 22 .

[0077] A plurality of leads 23 (first leads) are arranged on substantially the same plane around the die stage 22 . Each lead 23 has a portion called an inner lead 23A and an outer lead 23B through a tie bar (link) 24 . The inner lead 23A is closer to the die stage 22 (inner side) than the outer lead 23B located on the outer side.

[0078] Each inner lead 23A of the plurality of leads 23 is connected to an electrode terminal (such as a signal input / output terminal, a power supply terminal, or a ground terminal) of the semiconductor element 10 through a bonding wire 31 .

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com