Preparation method of high-impact liquid crystal polymer composite material

A technology of liquid crystal polymers and composite materials, which is applied in the field of preparation of high-impact liquid crystal polymer composite materials, can solve problems such as not being able to meet application requirements, meet the requirements of mass production and manufacturing, have a simple overall process, and have good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

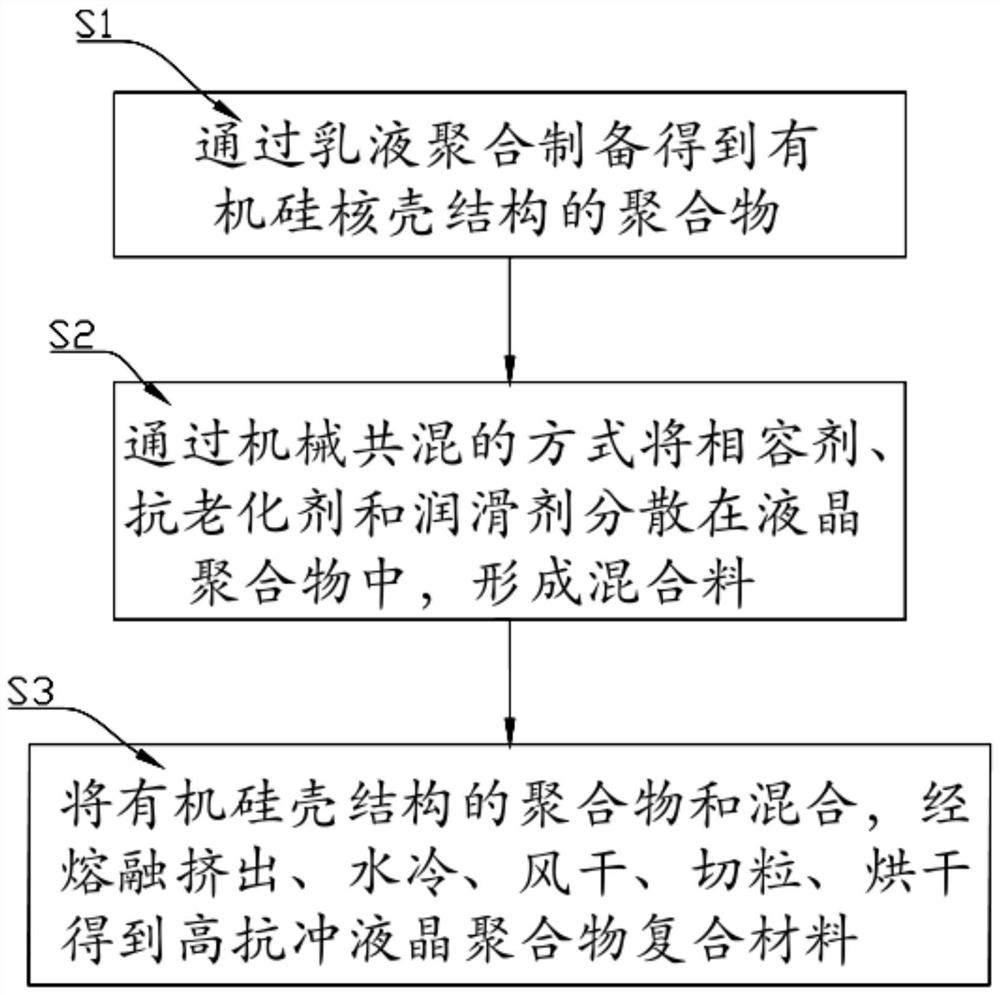

[0026] The preparation method of the high-impact liquid crystal polymer composite material provided by the invention comprises the following steps:

[0027] S1: A polymer with a silicone core-shell structure prepared by emulsion polymerization;

[0028] S2: Disperse the compatibilizer, anti-aging agent and lubricant in the liquid crystal polymer by mechanical blending to form a mixture;

[0029] S3: Melt extrusion, water-cooling, air-drying, pelletizing and drying of the polymer and the mixture with the silicone shell structure to obtain a high-impact liquid crystal polymer composite material.

[0030] Further, the steps for preparing a polymer with a silicone shell structure in S1 are as follows: add 100-150 g of distilled water, 0.1-0.3 g of sodium lauryl sulfate and 0.2-0.5 g of an emulsifier into the reaction vessel, stir and heat up to 70 -90°C, add 20-30g distilled water, 0.05-0.1g sodium lauryl sulfate, 0.05-0.1g emulsifier, 10g octamethylcyclotetrasiloxane and 1-2h si...

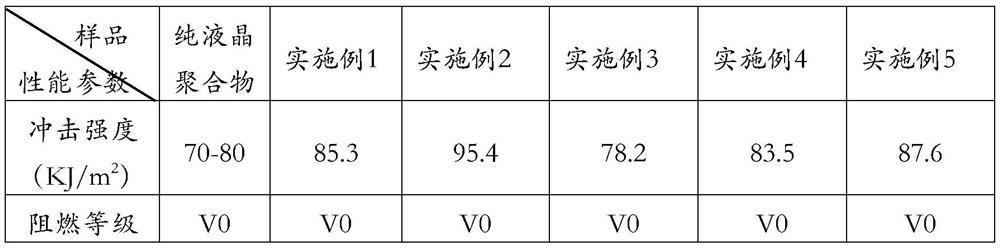

Embodiment 1

[0042] S1: Add 120g of distilled water, 0.15g of sodium lauryl sulfate, and 0.3g of emulsifier OP-10 into a 500ml four-necked flask equipped with a stirrer, a constant pressure drop funnel, a condenser and a thermometer, and keep stirring at a constant speed 200rpm, then raise the temperature of the oil bath to 80°C; then add 30g of distilled water, 0.05g of sodium lauryl sulfate and 0.1g of OP-10 into a beaker, and then add 10g of octamethylcyclotetrasilicon Oxygen and 2g of γ-methacryloxypropyl trimethoxysilane, after ultrasonic dispersion and mixing, slowly drop into the four-necked flask, react for 6h and cool to room temperature; then use 3% NaOH aqueous solution Adjust the pH value of the mixed solution in the four-neck flask to 10, then raise the temperature to 80°C, add 0.06g of ammonium persulfate, and then add 5g of acrylonitrile and 15g of styrene dropwise from the constant pressure dropping funnel. The mixed solution formed, the dropping speed is 5-8s / drop, continu...

Embodiment 2

[0046] S1: Add 120g of distilled water, 0.2g of sodium lauryl sulfate, and 0.5g of emulsifier OP-10 into a 500ml four-necked flask equipped with a stirrer, a constant pressure drop funnel, a condenser and a thermometer, and keep stirring at a constant speed 200rpm, then raise the temperature of the oil bath to 80°C; add 20g of distilled water, 0.06g of sodium lauryl sulfate and 0.1g of OP-10 into a beaker, and then add 10g of octamethylcyclotetrasilicon Oxygen and 2g of γ-methacryloxypropyltrimethoxysilane were ultrasonically dispersed and mixed uniformly, and then slowly added dropwise into a four-necked flask, reacted for 6 hours and then cooled to room temperature; then 3% NaOH aqueous solution Adjust the pH value of the mixed solution in the four-neck flask to 10, then raise the temperature to 80°C, add 0.08g of ammonium persulfate, and then add 6g of acrylonitrile and 17g of styrene dropwise from the constant pressure dropping funnel. The mixed solution formed, the droppi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com