Triple-cured material for dlp-type 3D printing and its preparation method and application

A 3D printing and triple curing technology, applied in the field of 3D printing materials, can solve problems such as high equipment requirements and costs, hidden safety hazards, and reduced laser power, and achieve good complementarity and synergy, reduced preparation costs, and excellent physical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

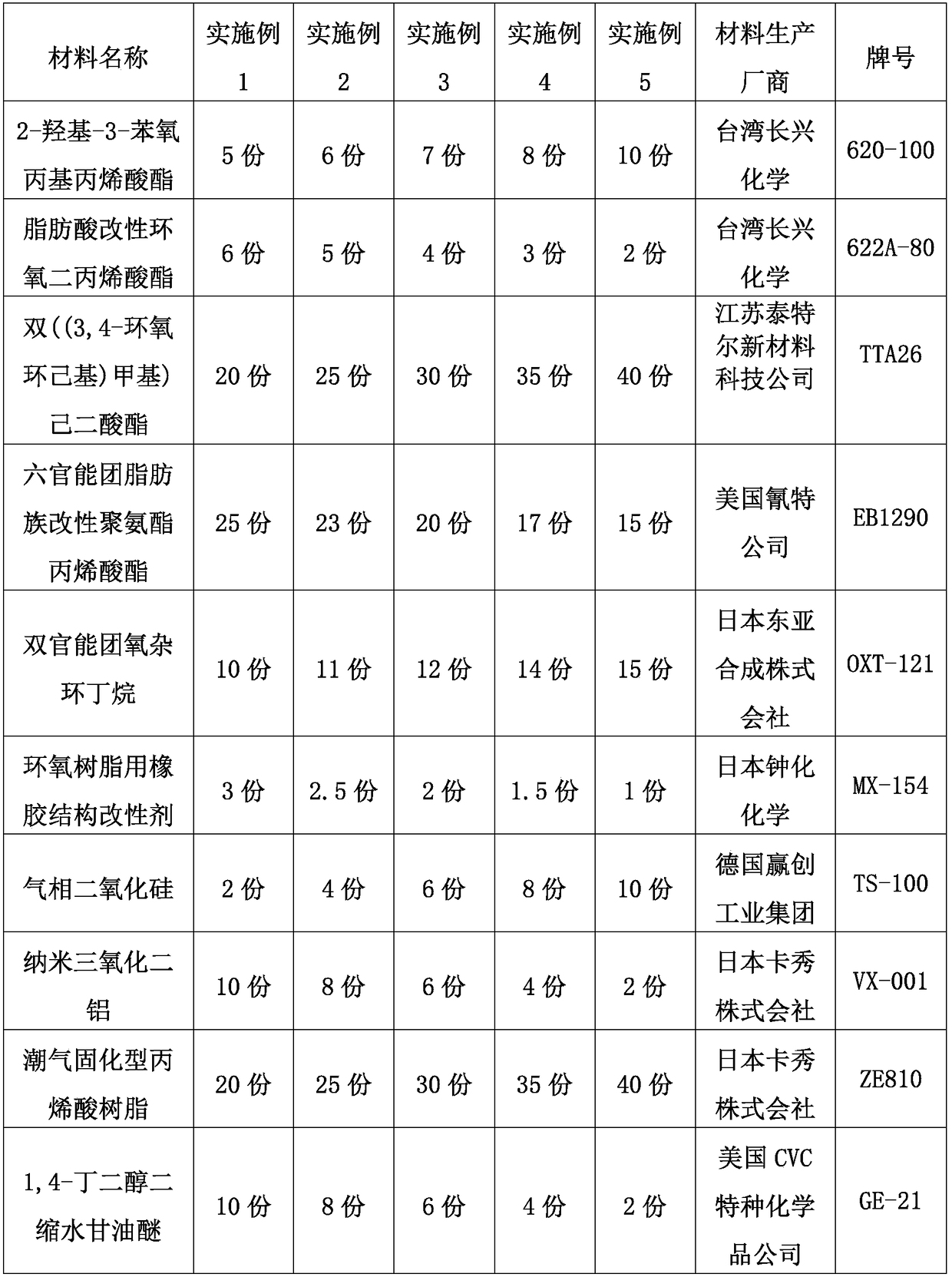

Embodiment 1

[0026] (1) 5 parts of 2-hydroxy-3-phenoxypropyl acrylate, 6 parts of fatty acid modified epoxy diacrylate and 20 parts of bis((3,4-epoxycyclohexyl)methyl) adipic acid The ester is put into the reaction tank and mixed, and stirred at a speed of 600 rpm for 30 minutes to obtain a premix; in this step, the operating temperature is controlled at 5-55°C.

[0027] (2) Add 25 parts of six-functional aliphatic modified urethane acrylate and 10 parts of bifunctional oxetane to the premix, add 3 parts of rubber structure modifier for epoxy resin after mixing, and use 650 Stir at a speed of rev / min for 15 minutes; from the addition of the hexafunctional aliphatic modified urethane acrylate to the end of the packaging, the stirring tank needs to be covered and protected with compressed air that sufficiently removes water vapor to minimize the contact time between the paint and water vapor ;Confirm the viscosity of the mixture after stirring, adjust the temperature of the mixture to 25°C, ...

Embodiment 2

[0031] Same as Example 1 operation steps, step (1) stirring speed 550 rpm, stirring time 35 minutes, control operating temperature 5~55 ℃; step (2) stirring speed 700 rpm, stirring time 10 minutes, controlling operating temperature 5-55°C; step (3) stirring speed 800 rpm, stirring time 10 minutes, control operating temperature 5-55°C; step (4) filter through 80-mesh steel wire filter.

Embodiment 3

[0033] Same as Example 1 operation steps, step (1) stirring speed 650 rpm, stirring time 25 minutes, control operating temperature 5~55 ℃; step (2) stirring speed 650 rpm, stirring time 12 minutes, controlling operating temperature 5-55°C; step (3) stirring speed 1000 rpm, stirring time 12 minutes, control operating temperature 5-55°C; step (4) filter through 80-mesh steel wire filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com