Nozzle cleaning apparatus

A technology for cleaning devices and nozzles, applied in the directions of spray devices, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems that the treatment liquid cannot fully clean the nozzles, damage and other problems, and achieve the effects of long life, variable life, and prevention of scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

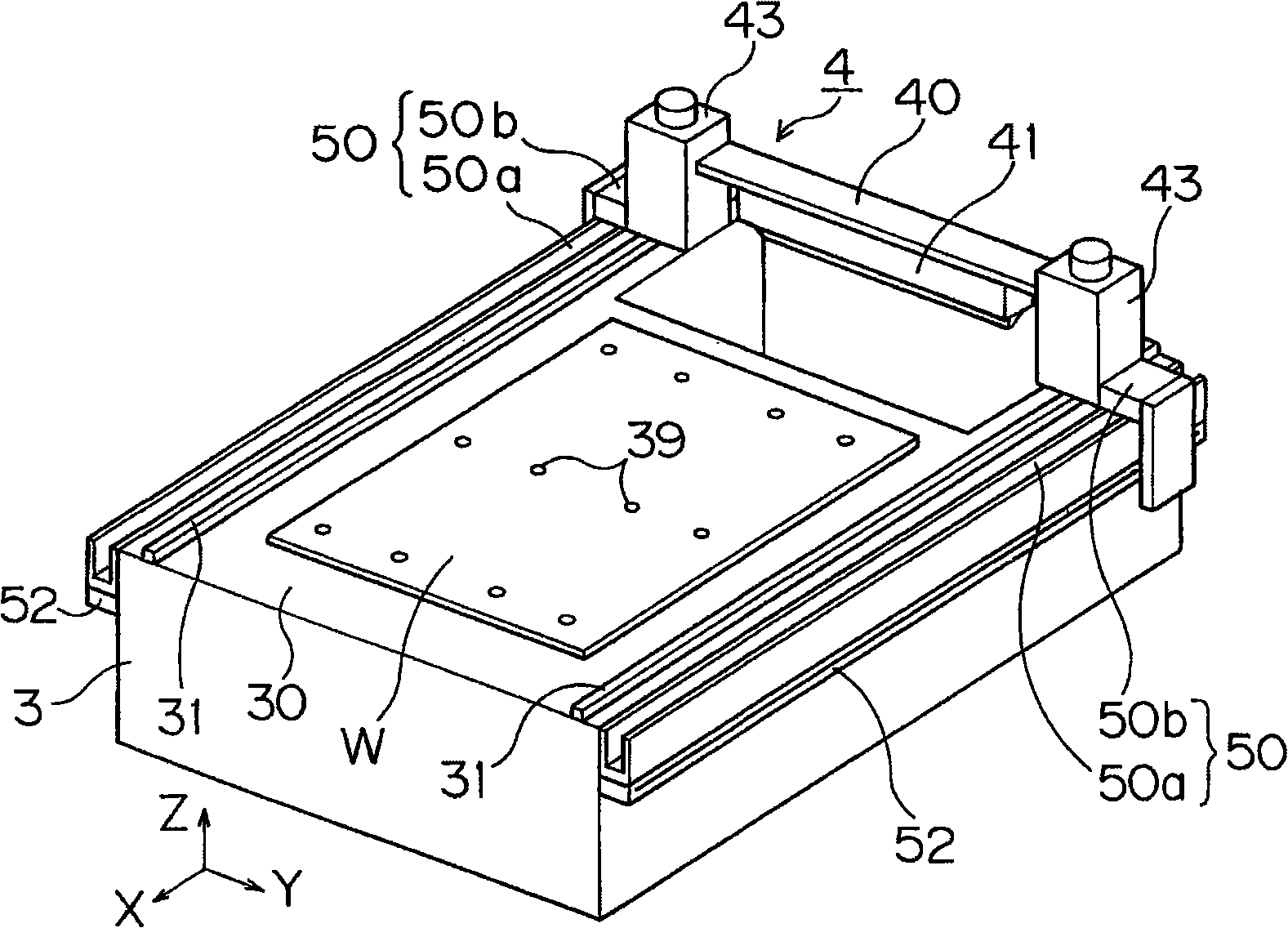

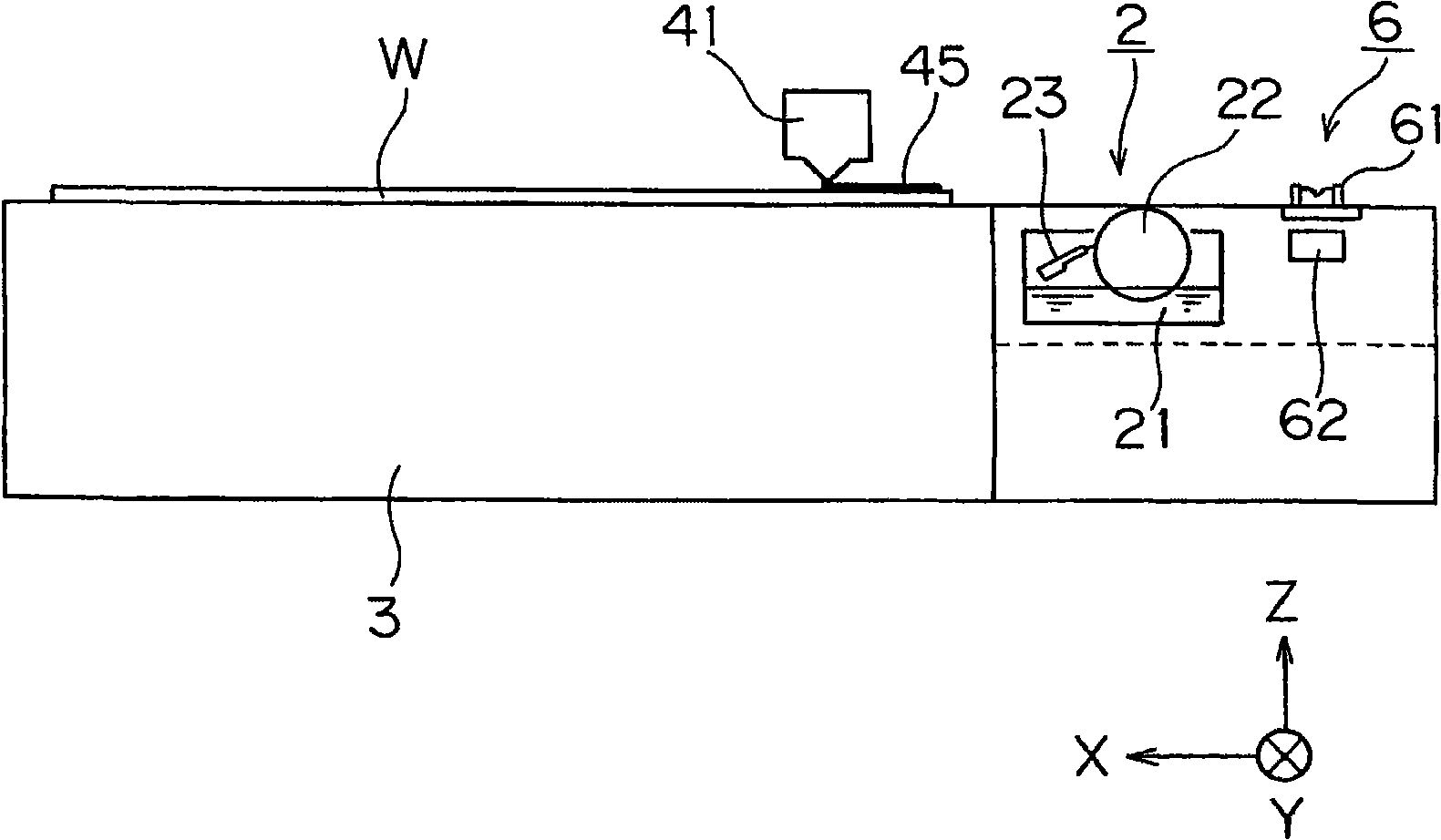

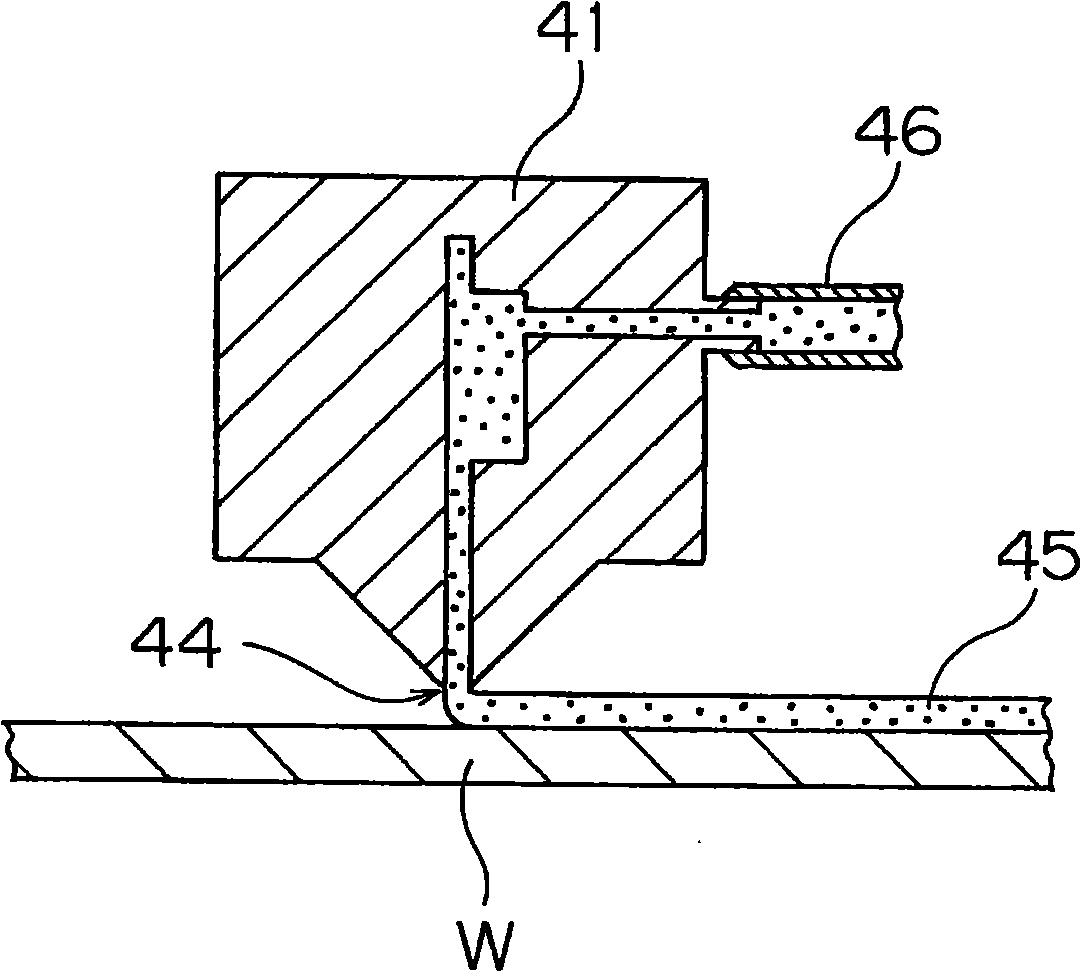

[0035] Embodiments of the present invention will be described below with reference to the drawings. figure 1 is a perspective view of a coating device to which the nozzle cleaning device of the present invention is applied, figure 2 is its side view. In addition, in figure 1 The illustration of the pre-dispense mechanism 2, the nozzle cleaning device 6, etc. is omitted in FIG. In addition, in figure 2 The illustration of the carrier 4 etc. is omitted in FIG.

[0036] This coating device is used to coat, for example, a resist including a pigment called a color resist on a glass substrate (hereinafter referred to as “substrate”) W for a rectangular liquid crystal panel.

[0037] This coating apparatus includes a stage 3 for holding a substrate W. As shown in FIG. The stage 3 is made of a cuboid-shaped stone, and its upper surface is a horizontal plane, which serves as a holding surface 30 for the substrate W. As shown in FIG. A plurality of vacuum suction ports (not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com