Composite refrigeration method and device for high-power electric semiconductor device

A technology for power semiconductors and cooling devices, which is applied in the fields of semiconductor devices, semiconductor/solid-state device components, and electric solid-state devices, etc. The problem of large temperature difference of the radiator can save one-time investment, improve work efficiency and heat dissipation effect, and improve cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

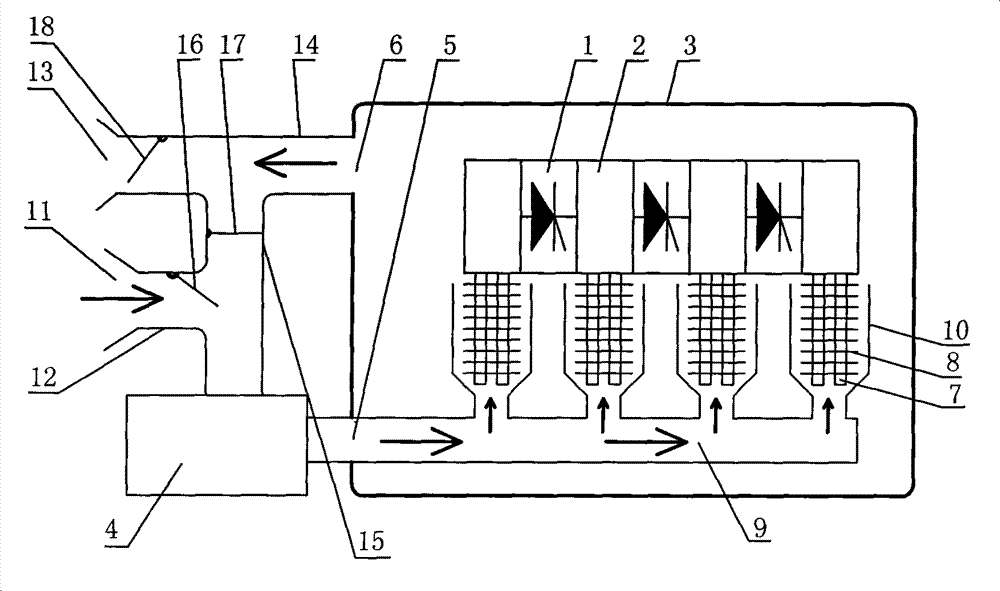

[0102] The system flow chart shown in Figure 5 is used. Since it is an engineering drawing, the marks, codes and meanings used in the drawing are marked according to the requirements and conventions of engineering drawings and national standards.

[0103] In the figure, the cold air (marked as fresh air) enters through the cold air pipe and the first electric control valve FM14, passes through the filter GLQ, the surface cooler BLQ, the water baffle DSB and the frequency conversion fan FJ in turn, and passes through the air supply temperature collector. The air supply main pipe of W1 and the air flow meter V and each air supply sub-channel equipped with the air supply sub-regulating valve FMn (n=1~11) are forced / directly transported to each cooling rib / fin group CU n(n =1~11).

[0104] In order to obtain a better operation / cooling effect, surface temperature collectors Wn (n=2-11) are arranged on each power semiconductor device.

[0105] After the heat absorption, the hot air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com