Separator for electric double layer capacitor

A technology for electric double-layer capacitors and separators, which is applied in the direction of electrolytic capacitors, hybrid capacitor separators, capacitors, etc., can solve problems such as internal resistance, leakage capacity maintenance rate, vibration resistance, etc., and achieve high electrostatic capacity maintenance rate, The effect of reducing the unevenness of electrostatic capacity and enhancing the puncture strength

Inactive Publication Date: 2008-12-03

MITSUBISHI PAPER MILLS LTD

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this spacer has problems in internal resistance, leakage current, capacity retention rate, and vibration resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

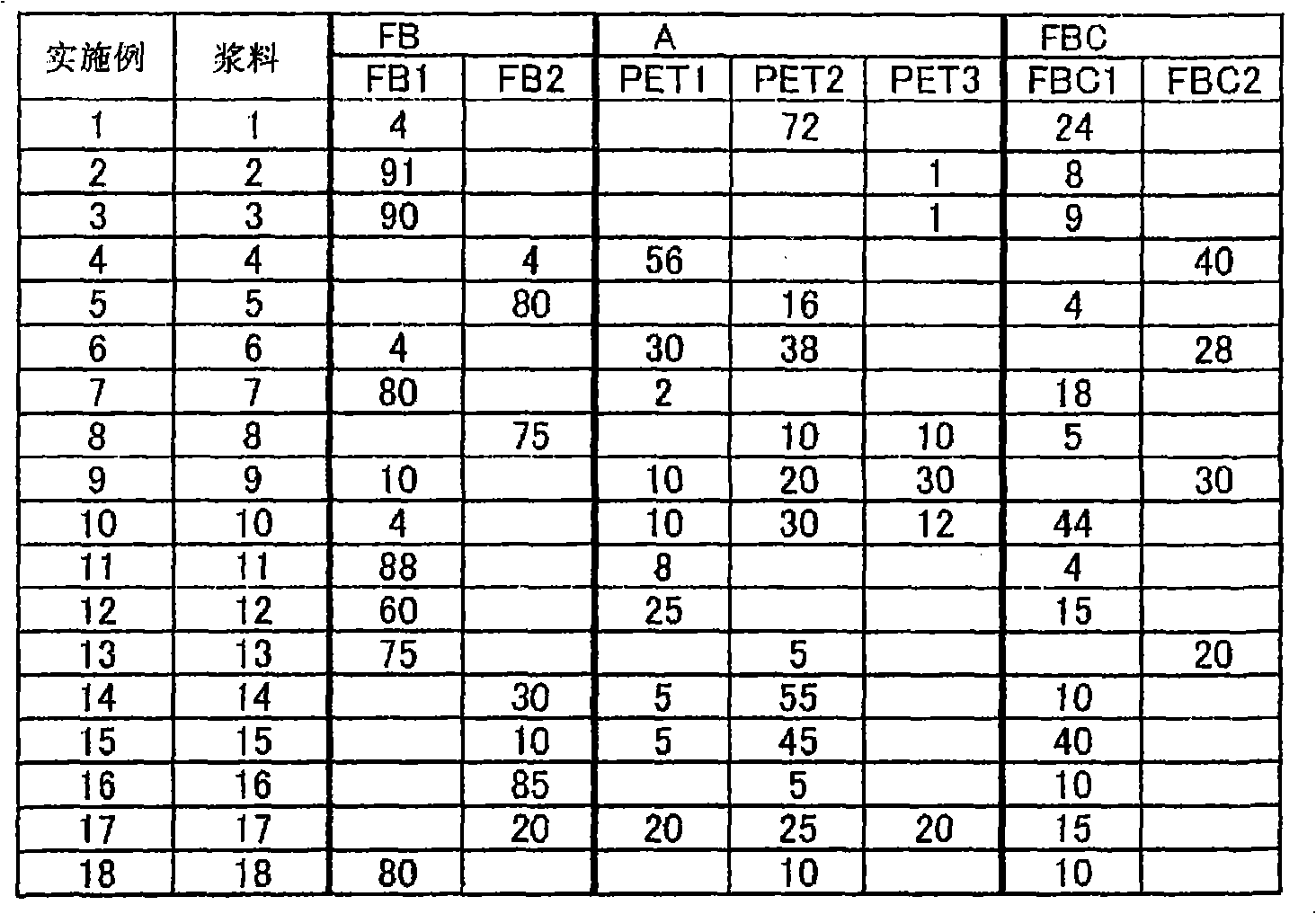

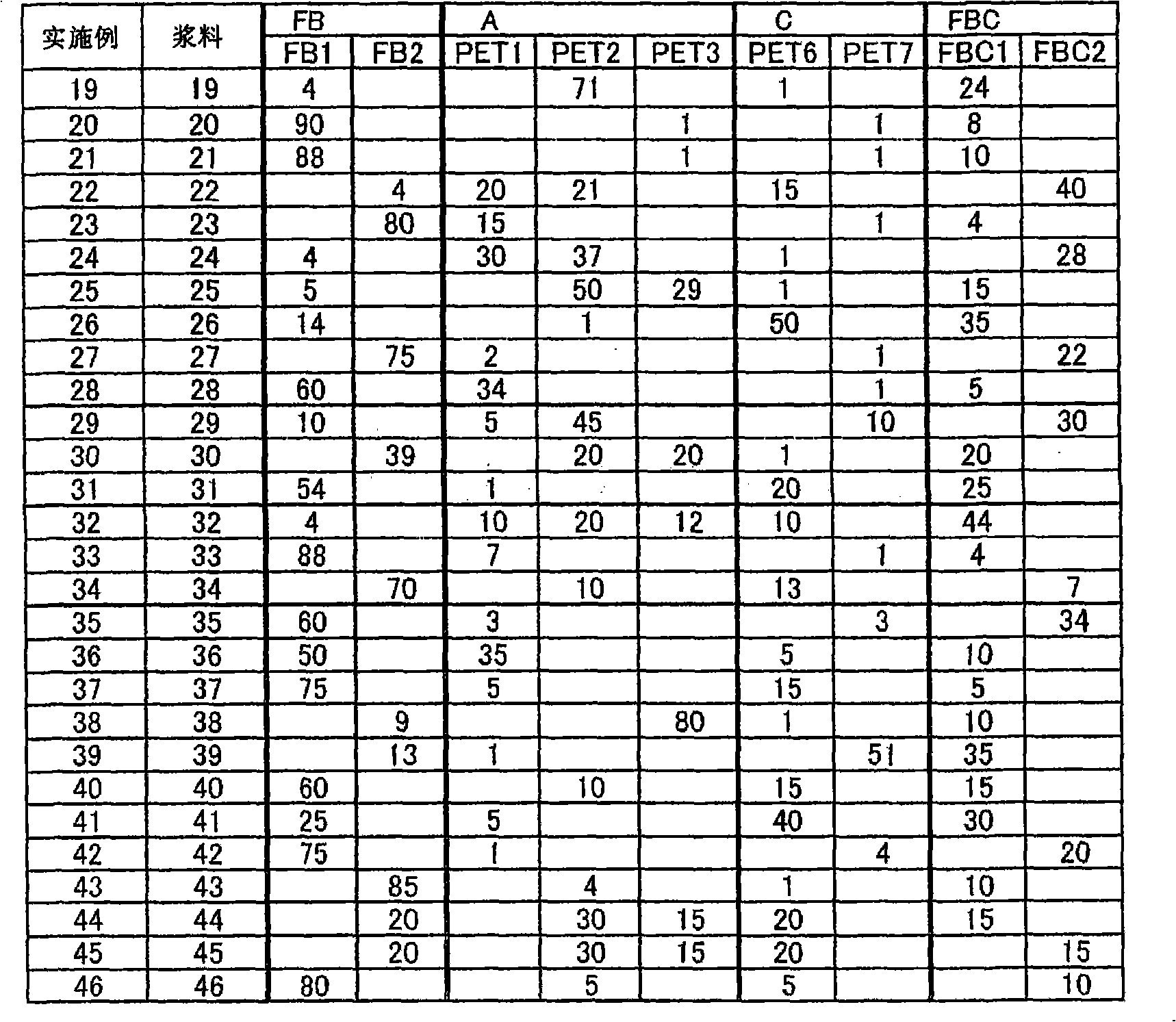

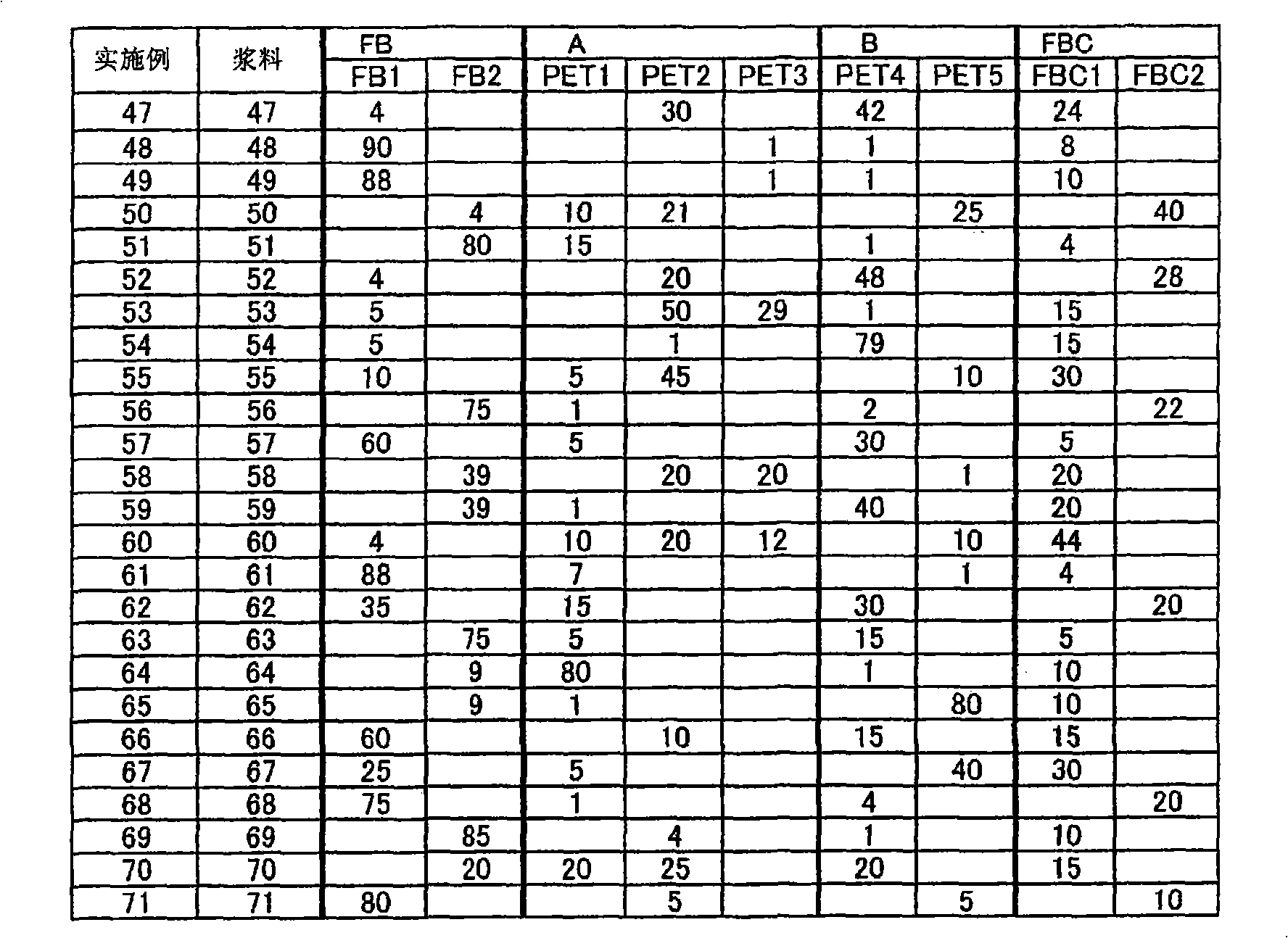

Embodiment 1~96

[0087] Slurries 1-96 were subjected to wet papermaking to produce porous sheets 1-96. Next, the porous sheets 1 to 96 were calendered under the conditions shown in Table 11 to produce separators 1 to 96 for electric double layer capacitors. As the paper machine, a combined paper machine of a cylinder paper machine and an inclined short wire paper machine was used.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Disclosed is a separator for electric double layer capacitors which is composed of a porous sheet containing a fibrillated heat-resistant fiber, a polyester fiber having a fineness of not less than 0.01 dtex and less than 0.10 dtex, and a fibrillated cellulose. The separator for electric double layer capacitors is suitable for an electric double layer capacitor which operates at a high voltage of not less than 3 V.

Description

technical field [0001] The present invention relates to a separator for electric double layer capacitors. Background technique [0002] Conventionally, paper separators mainly composed of solvent-spun cellulose fibers or regenerated cellulose fibers have been used as separators for electric double layer capacitors (for example, refer to Patent Documents 1 to 3). Conventionally, electrodes made of activated carbon have been used as electrodes for electric double layer capacitors, but the energy density and power density are insufficient for applications such as auxiliary power supplies for automobiles and trains. Since the energy density and power density increase in direct proportion to the square of the voltage, the improvement of electrode materials is active. Compared with the upper limit voltage of the previous activated carbon electrode, which is about 2.5-2.7V, the upper limit voltage of the recently developed activated carbon electrode is about 3.7-4.2V. working elec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01G9/02

CPCH01G11/52Y02E60/13H01G9/02Y10T428/268Y10T442/68Y10T442/615Y10T442/681Y10T442/626Y10T442/697Y10T442/693Y10T442/614Y10T442/698

Inventor 佃贵裕绿川正敏佐藤友洋

Owner MITSUBISHI PAPER MILLS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com