Touch control type display panel, colorful color filter and its production method

A color filter and color filter technology, which is applied in optics, optical components, nonlinear optics, etc., can solve the problems of easily limited electrode configuration and quantity, complicated process, and complex process, so as to improve the sensing resolution , Simplified process steps, good touch resolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

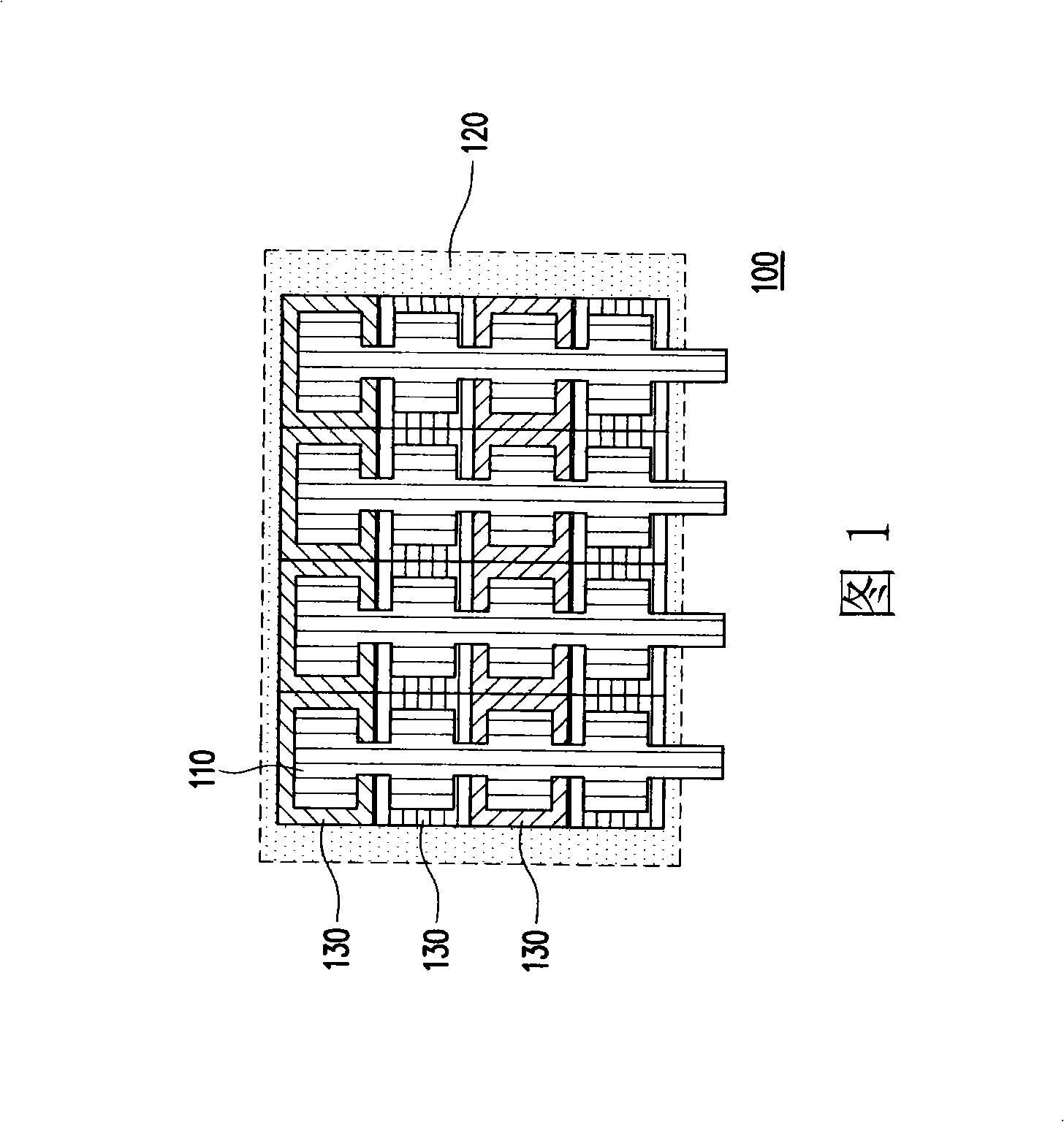

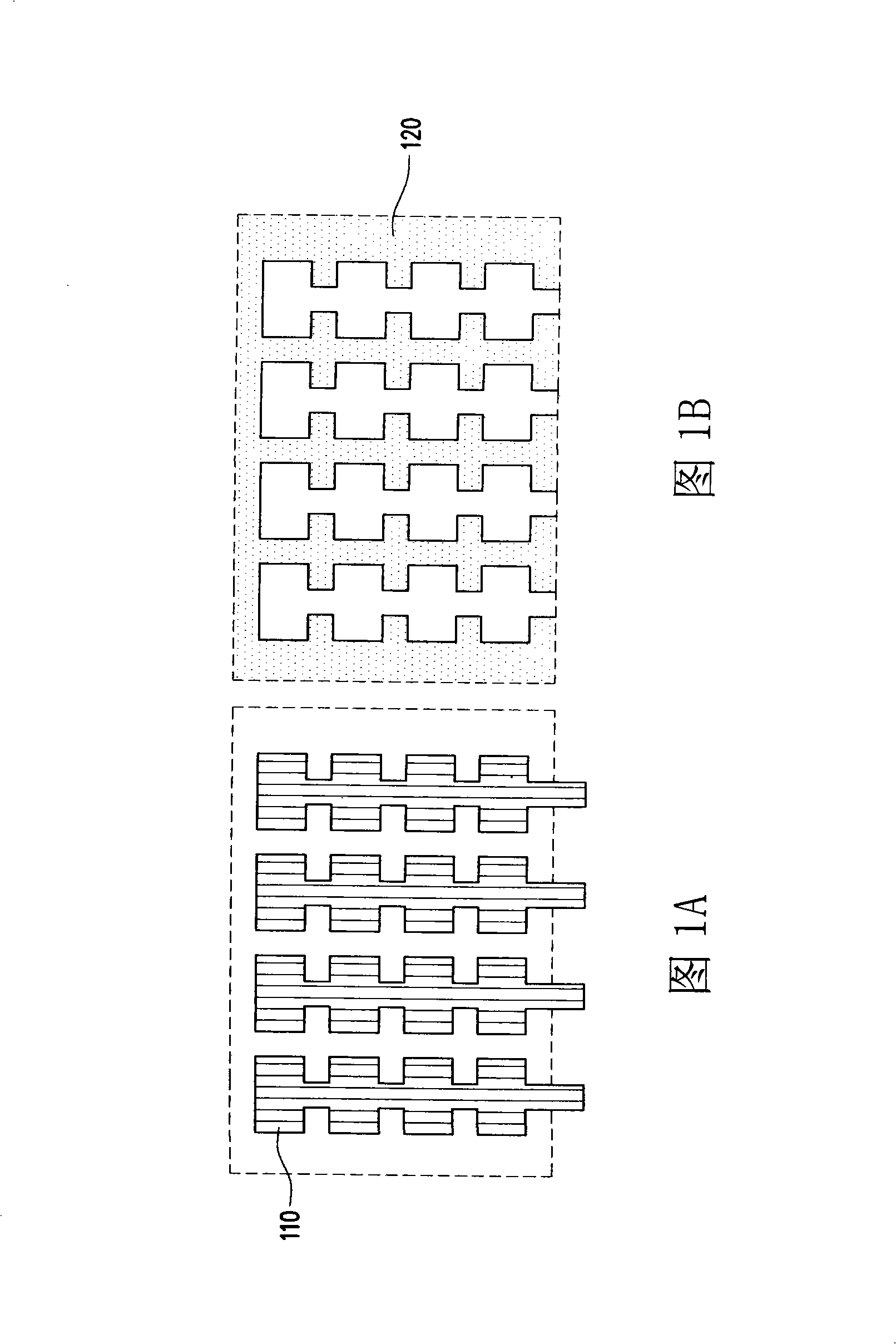

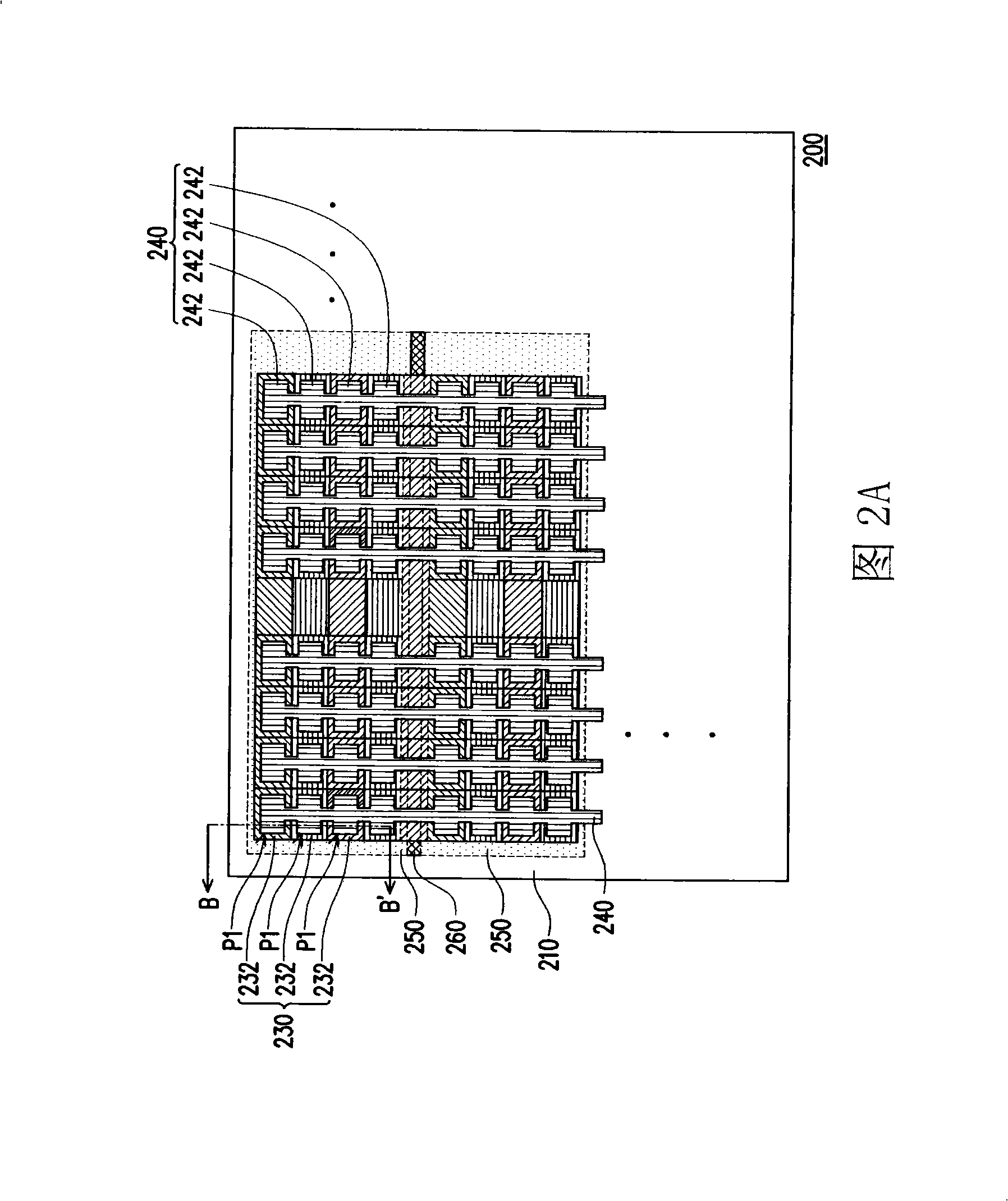

[0074] 2A is a schematic top view of the touch-sensitive color filter according to the first embodiment of the present invention, and FIG. 2B is a schematic cross-sectional view of the touch-sensitive color filter drawn along the line BB' in FIG. 2A . For clarity, FIG. 2A mainly shows the structure of the sensing electrodes, while omitting other upper layers such as the third dielectric layer and the shared electrode layer. However, FIG. 2B depicts the connection relationship between the substrate and each film layer in detail.

[0075] The touch-sensitive color filter 200 of this embodiment includes a substrate 210, a black matrix 220, a color filter layer 230, and a second electrode layer 240, wherein the connection relationship of each component of the touch-sensitive color filter 200 is shown in FIG. 2A and Figure 2B depicts.

[0076] The connection relationship among the components of the touch-sensitive color filter 200 will be described in detail below.

[0077] In th...

no. 2 example

[0097] 3A is a schematic top view of a touch-sensitive color filter according to a second embodiment of the present invention, and FIG. 3B is a schematic cross-sectional view of the touch-sensitive color filter drawn along line CC' in FIG. 3A . For clarity, FIG. 3A mainly shows the structure of the sensing electrodes, while omitting other layers such as the first dielectric layer, the third dielectric layer, and the shared electrode layer. FIG. 3B depicts the connection relationship between the substrate and each film layer in detail.

[0098] Please refer to FIG. 2A , 2B, 3A and FIG. 3B at the same time. The structure of the touch-sensitive color filter 300 is similar to that of the touch-sensitive color filter 200 , and the similarities will not be repeated here. The only difference between the two is that the touch-sensitive color filter 300 further includes a first dielectric layer 310, wherein the first dielectric layer 310 covers the color filter layer 230 and the black ...

no. 3 example

[0103] FIG. 4A is a schematic top view of a touch-sensitive color filter according to a third embodiment of the present invention, and FIG. 4B is a schematic cross-sectional view of the touch-sensitive color filter drawn along line DD' in FIG. 4A . For clarity, FIG. 4A mainly shows the structure of the sensing electrodes, while omitting other layers such as the second dielectric layer, the third dielectric layer, and the shared electrode layer. FIG. 4B depicts the connection relationship between the substrate and each film layer in detail.

[0104] Please refer to FIG. 4A and FIG. 4B at the same time. The touch-sensitive color filter 400 of this embodiment is formed by adjusting the film layer order of the touch-sensitive color filter 200 . Therefore, the same components are marked with the same symbols. In addition, the touch-sensitive color filter 400 further includes a second dielectric layer 410 . The second dielectric layer 410 is disposed between the black matrix 220 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com