Cutting rod, cutting bit and cutting tool

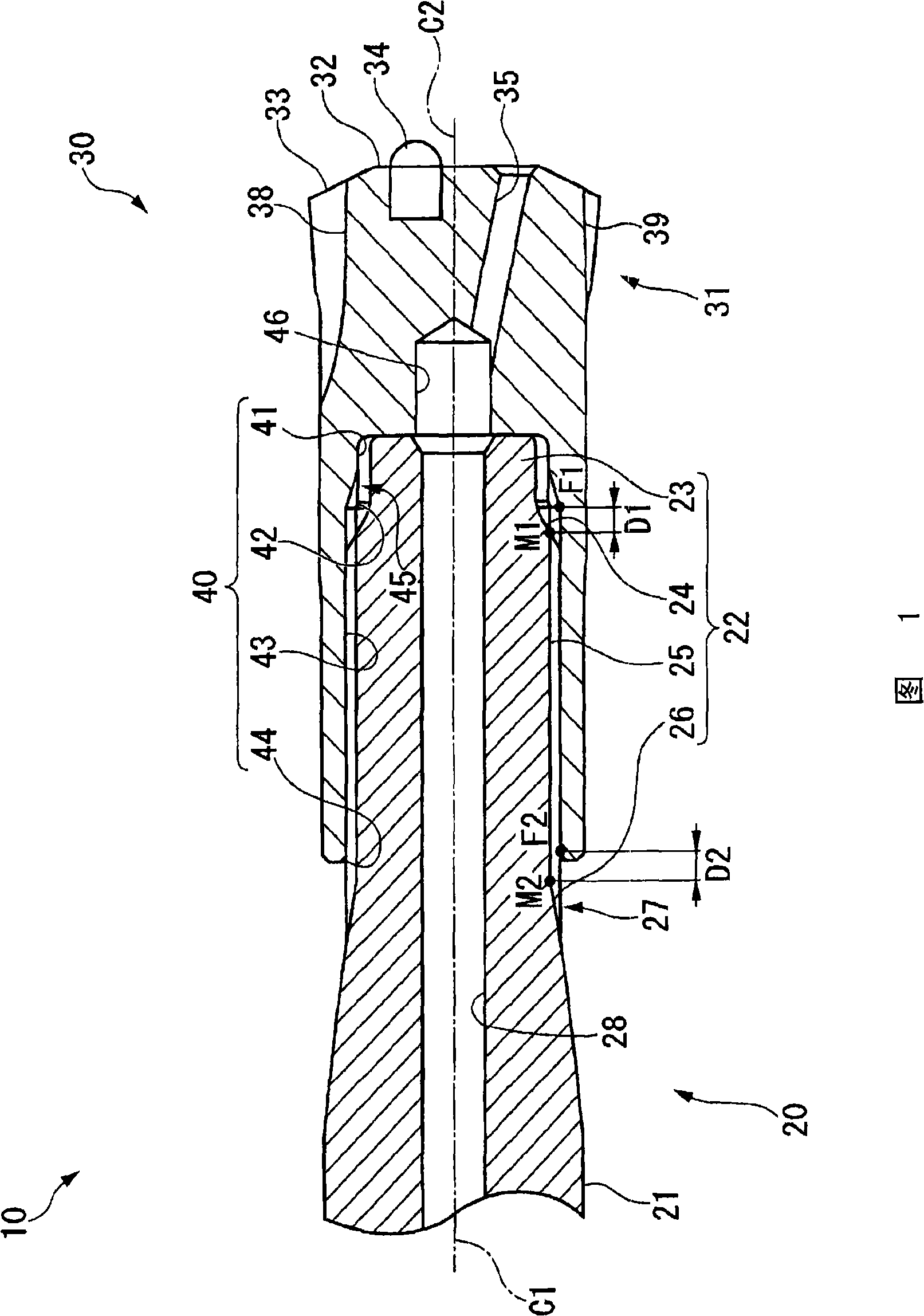

A technology of drill pipes and drill bits, which is applied in the fields of drill pipes, drill bits, and drilling tools. It can solve the problems of thinning the wall thickness of the drill bit, increasing the load of the drilling tool, and uneconomical problems, so as to achieve easy processing, suppress breakage, and ensure wall thickness. thick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

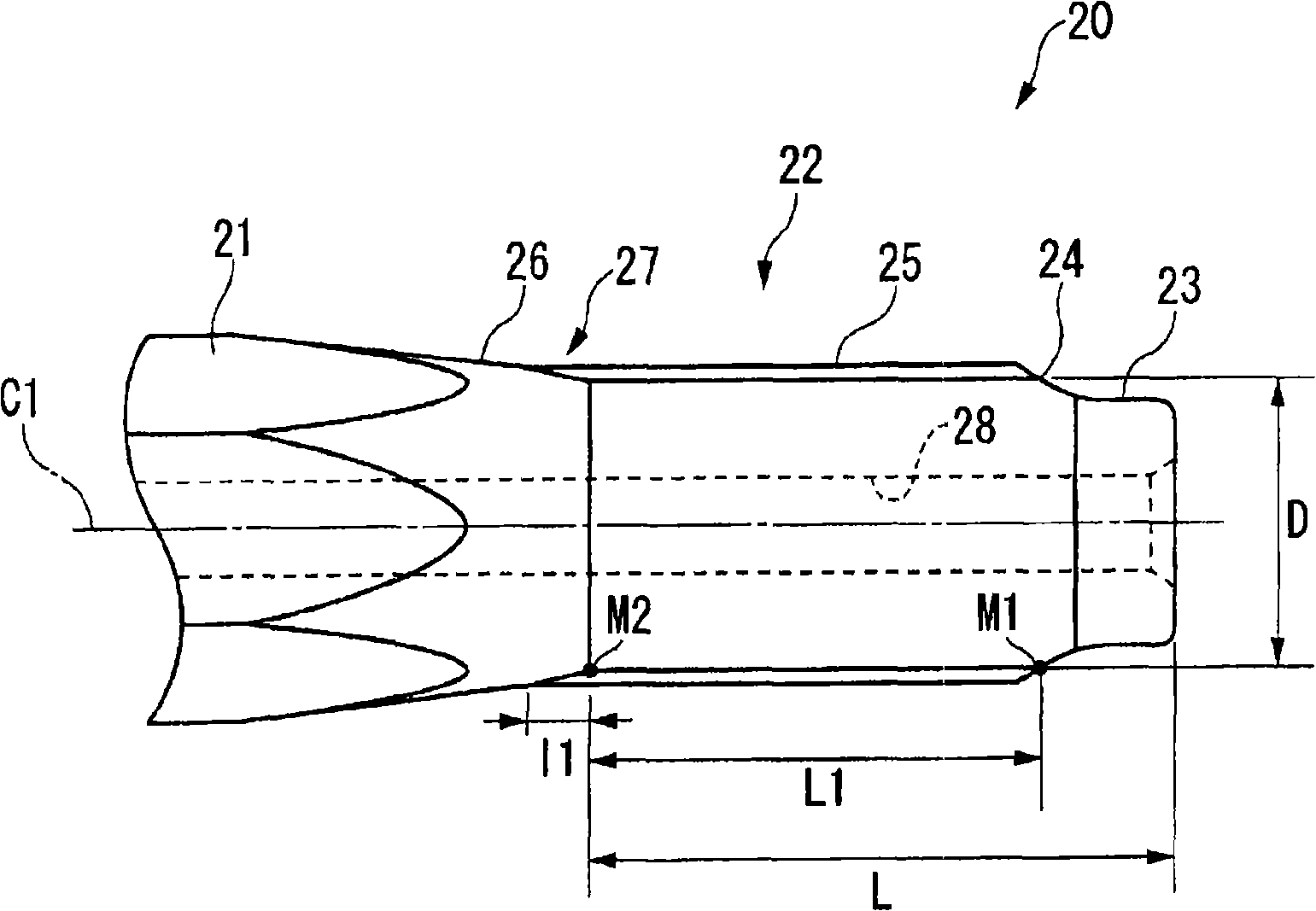

[0108] The result of studying the length l1 of the parallel male thread portion in the present invention will be described below.

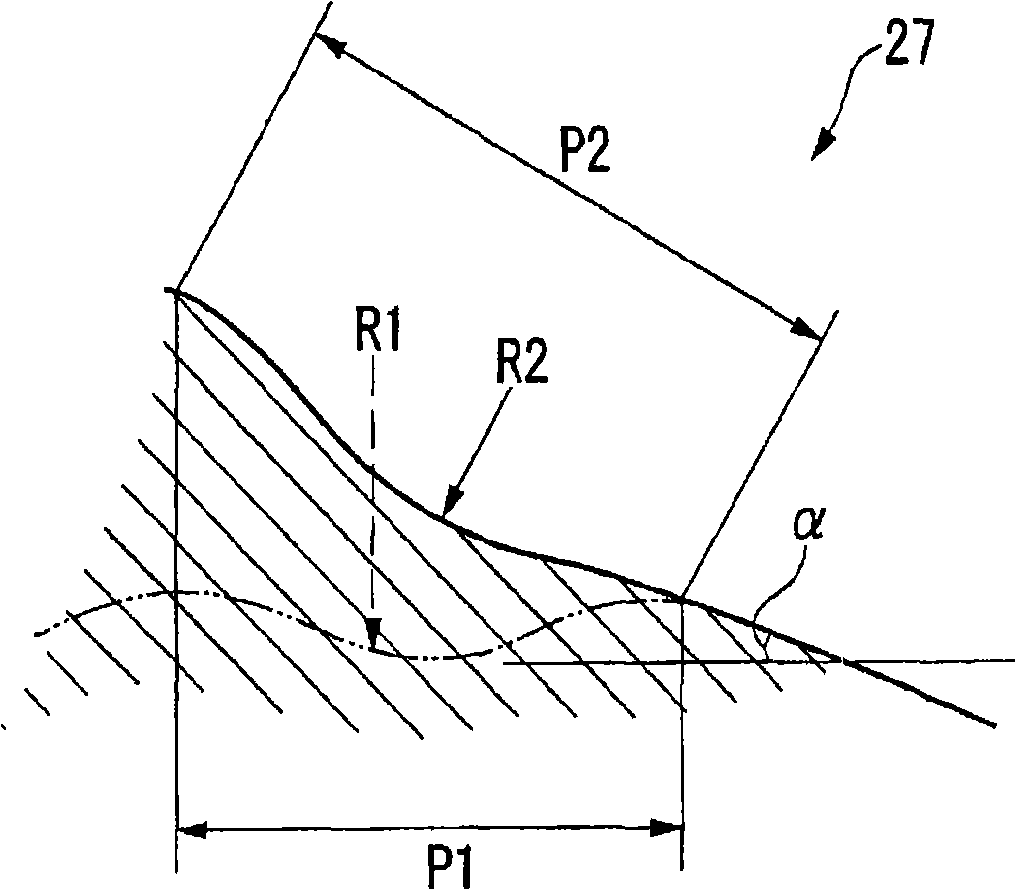

[0109] In consideration of the rigidity of the drill rod, the length L1 of the parallel male thread portion obtained by cutting off the outer peripheral surface of the drill rod is preferably short. In particular, the portion that is subjected to a bending load during drilling and is long in length from the tip and small in outer diameter has the greatest stress and is likely to cause breakage, so the length of the parallel male thread portion forming the thread groove is preferably short.

[0110] On the other hand, axial loads applied by rotational force and thrust act on the thread portion. Therefore, in consideration of the load applied to each thread, it is preferable that the number of threads is large and the length L1 of the parallel male thread portion be long.

[0111] Therefore, FEM analysis was performed on the length of the parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com