Gallium nitride semiconductor light emitting element

A technology of light-emitting elements and semiconductors, which is applied in the manufacture of semiconductor devices, semiconductor lasers, semiconductor/solid-state devices, etc., and can solve problems such as increased driving voltage, large electric field E, and increased piezoelectric polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

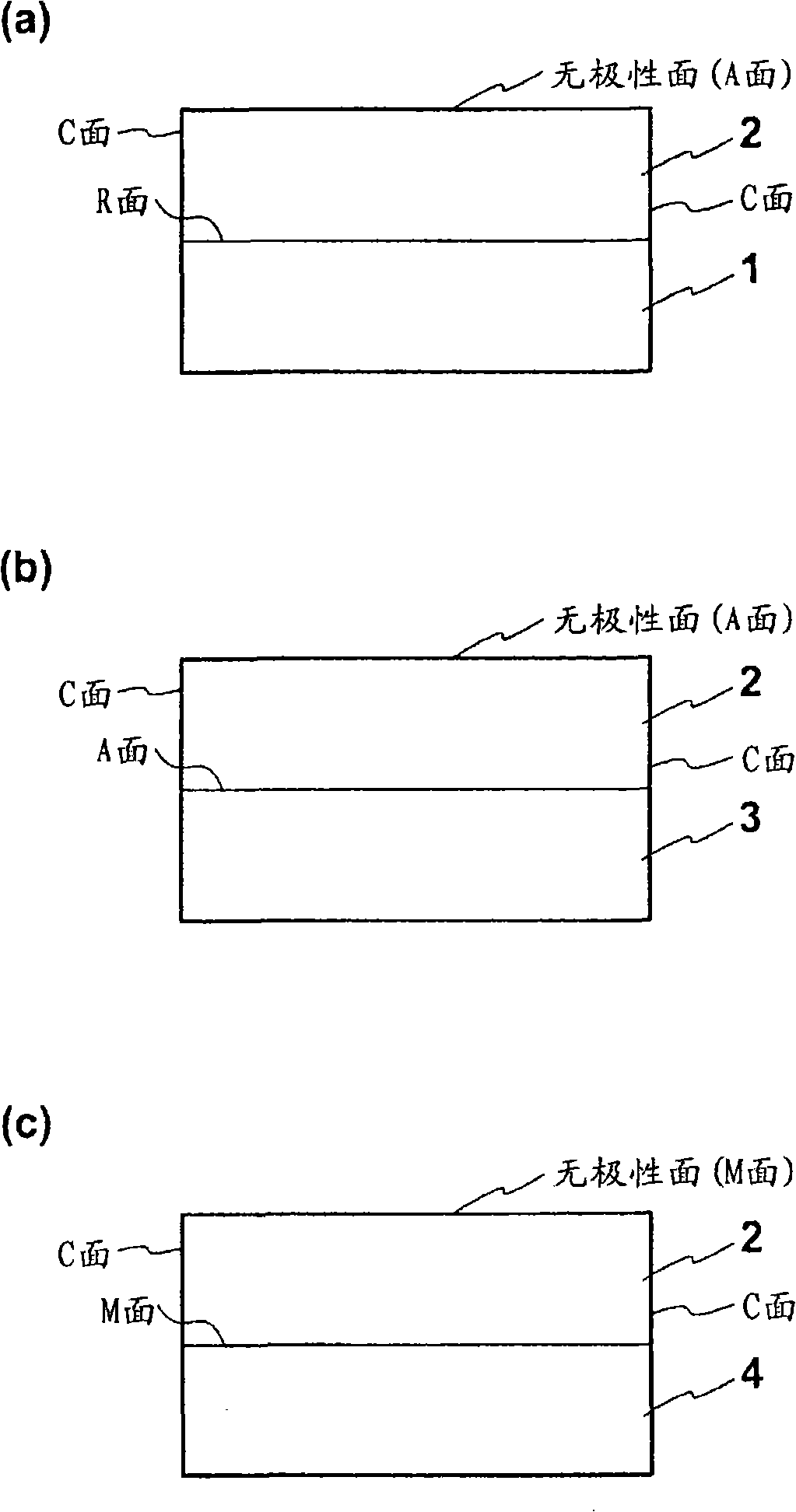

[0031] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. figure 1 A schematic configuration of the gallium nitride semiconductor light-emitting device of the present invention is shown. figure 1 In the gallium nitride semiconductor light-emitting element of (a), a gallium nitride semiconductor crystal 2 including a light-emitting region is formed on a sapphire substrate 1 . The gallium nitride semiconductor crystal 2 is formed on the R surface (1-102) of the sapphire substrate 1 by MOCVD or the like, and its growth surface is grown on the A surface. refer to Figure 8 , 9 It can be seen that the A surface is not a Ga polar surface and an N (nitrogen) polar surface, but a nonpolar surface.

[0032] In addition, Japanese Patent Application Laid-Open No. 2000-216497 shown in Patent Document 1 describes that GaN-based semiconductor layers can be stacked on the A-side and M-side of a sapphire substrate, and the growth surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com