Pipe fitting butt welding protecting method and apparatus

A technology of protective devices and pipe fittings, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of wasting welding protective gas, long inflation time, affecting welding efficiency, etc., and achieve the effect of improving efficiency and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

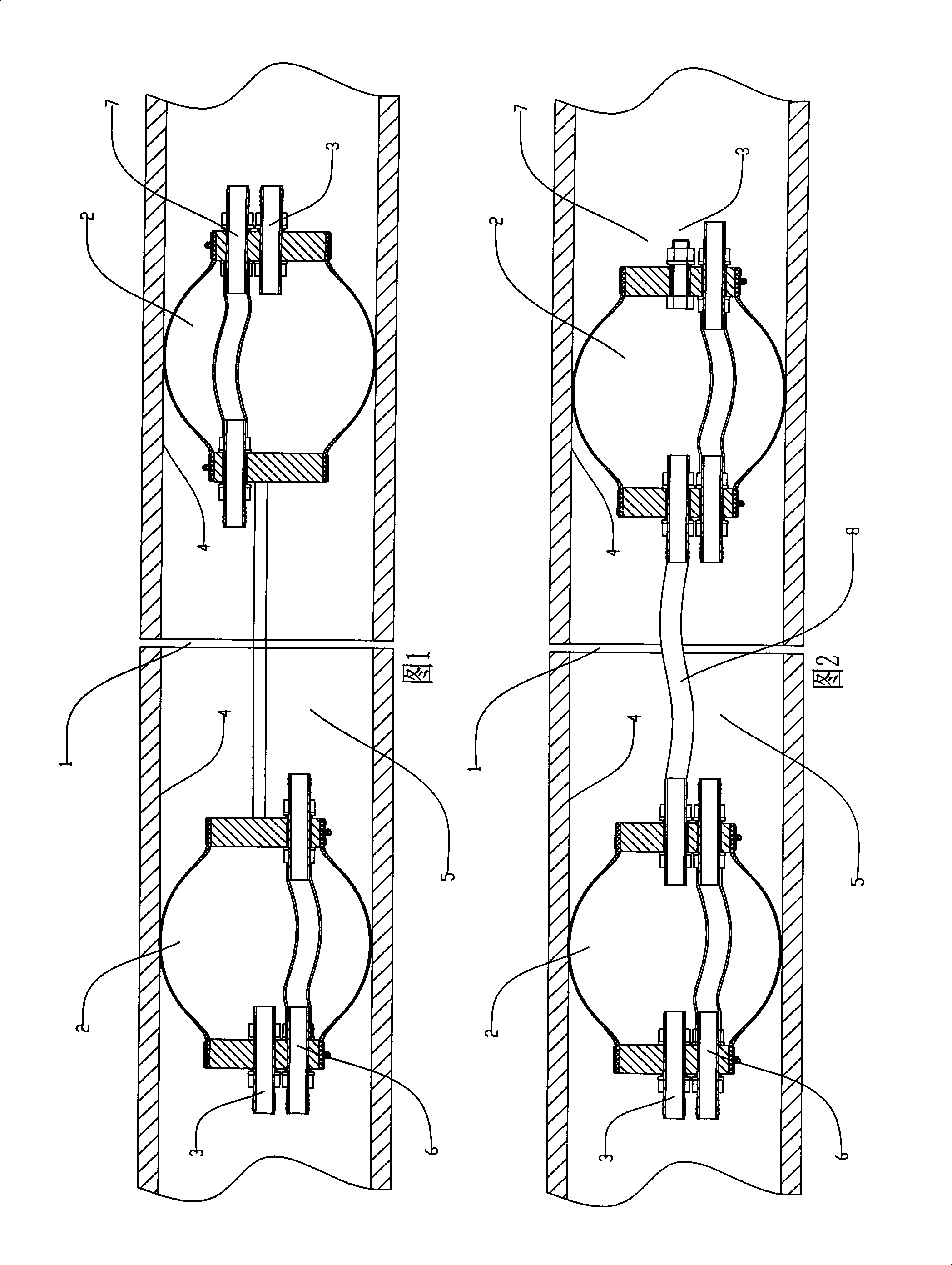

[0017] A pipe fitting butt welding protection device, as shown in Figure 1, has two inflatable airbags 2 installed on both sides of the pipe fitting butt joint 1, the two airbags are connected to each other, and each airbag is connected with its own expansion tube 3, through the expansion tube 3 Inflating the gas can make the two airbags 2 expand and cling to the pipe wall 4, thereby forming a cavity 5 separated from the outside world with the pipe wall. The airbag is also equipped with an inflation pipe 6 and an exhaust pipe 7 that run through the airbag. The welding protection Gas can be charged into the cavity 5 through the gas filling tube 6 , and the air in the cavity 5 can be discharged through the exhaust tube 7 .

[0018] When the pipe fittings are butt welded, first insert the pipe fitting butt welding protection device into one of the butt pipe fittings, and then pull the protection device to the direction of the other pipe fitting to the butt joint of the pipe fittin...

Embodiment 2

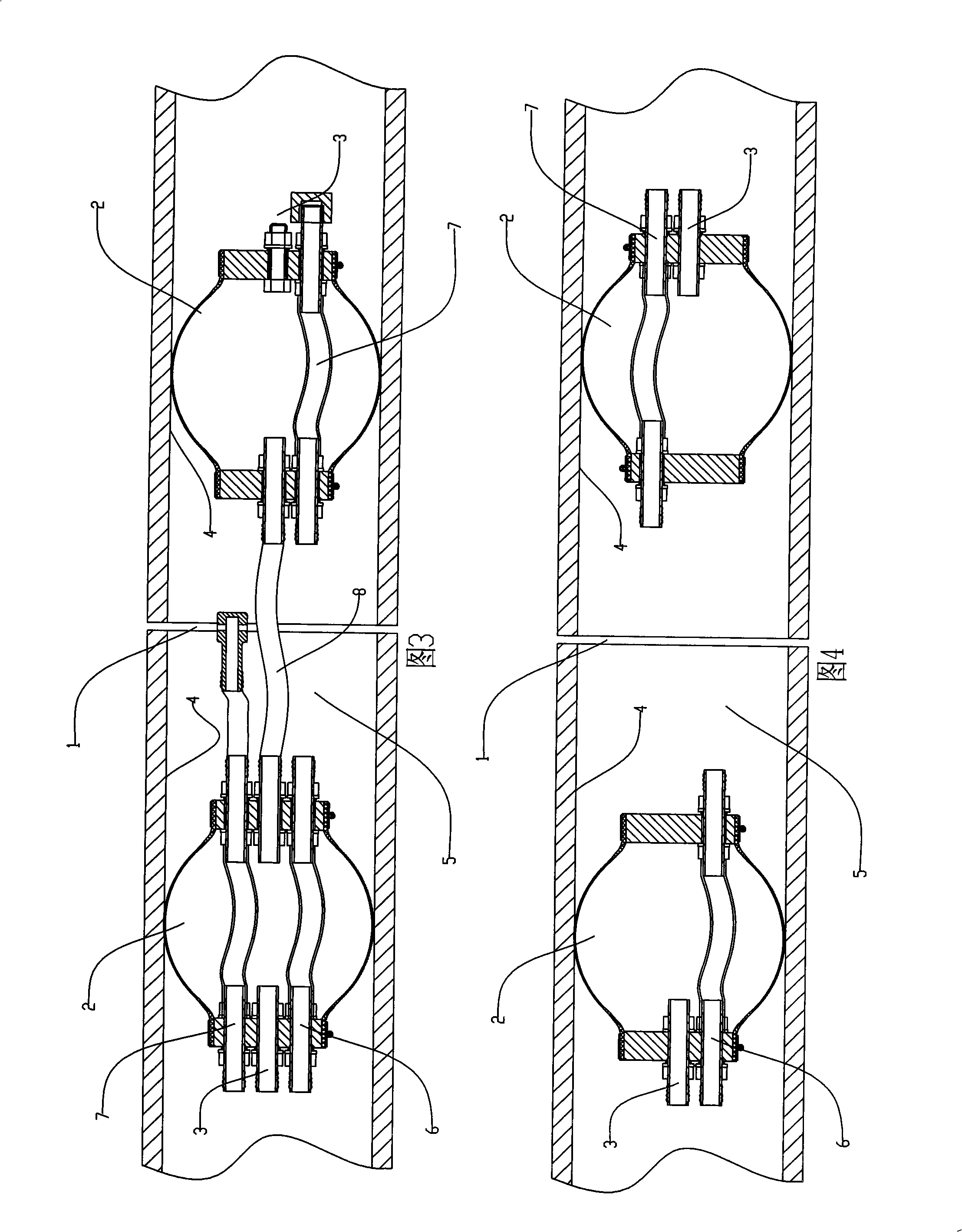

[0022] A butt welding protection device for pipe fittings, as shown in Figure 4, differs from Embodiment 1 in that the two airbags 2 are independent and not connected to each other, and are the same as Embodiment 1 in other respects.

[0023] Because the pipe fittings welded to the pipe are sometimes very long, the installation method of installing the pipe welding protection device from one end and then pulling it to the welding seam in the first embodiment is sometimes very inconvenient. Not only is it difficult to install the pulling rope that extends from the other end of the pipe, but it is also difficult to control the distance that the protective device is pulled. position on both sides of the seam. In this embodiment, the two airbags are separated independently. When the pipes are welded, the two airbags can be directly put into the two pipes respectively from the welding ends of the two pipes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com