Magnetic sensor and production method thereof

A magnetic sensor and sensor technology, applied in the field of magnetic sensors, can solve the problems of low accuracy and tilted position accuracy, and achieve the effects of increasing productivity, reducing the number and improving the production yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

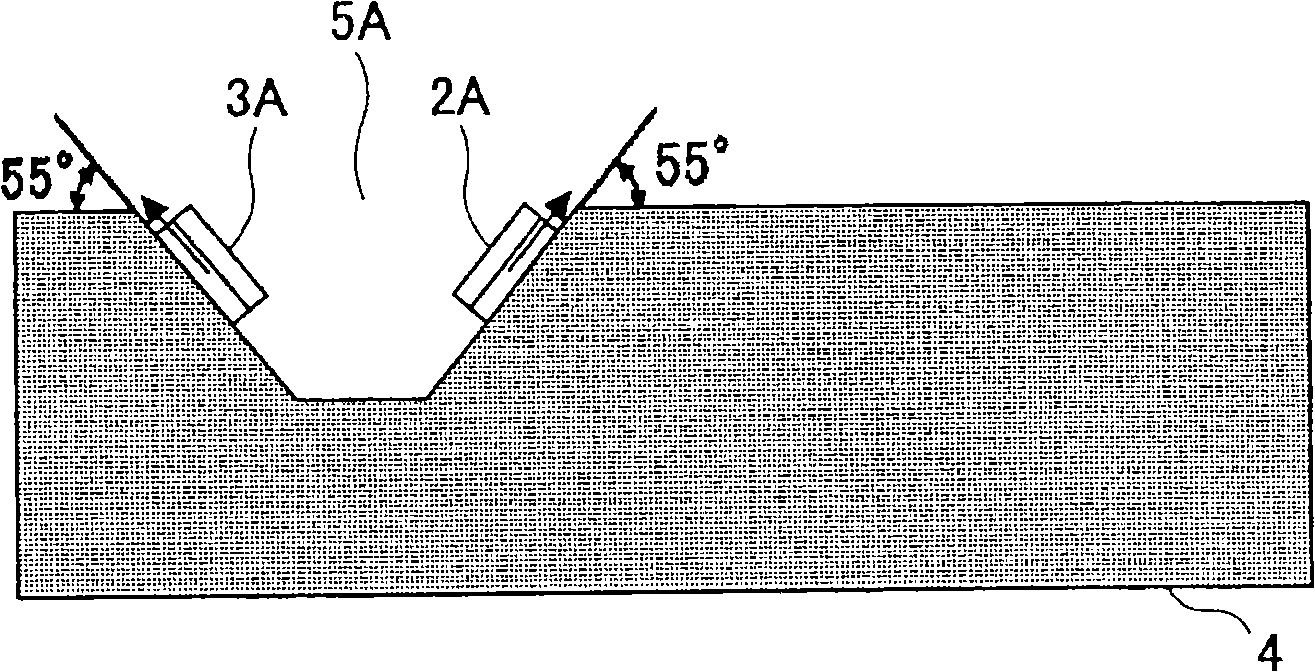

[0102] In this embodiment, the magnetic field detectors are arranged in the same inclined surface with a certain angle.

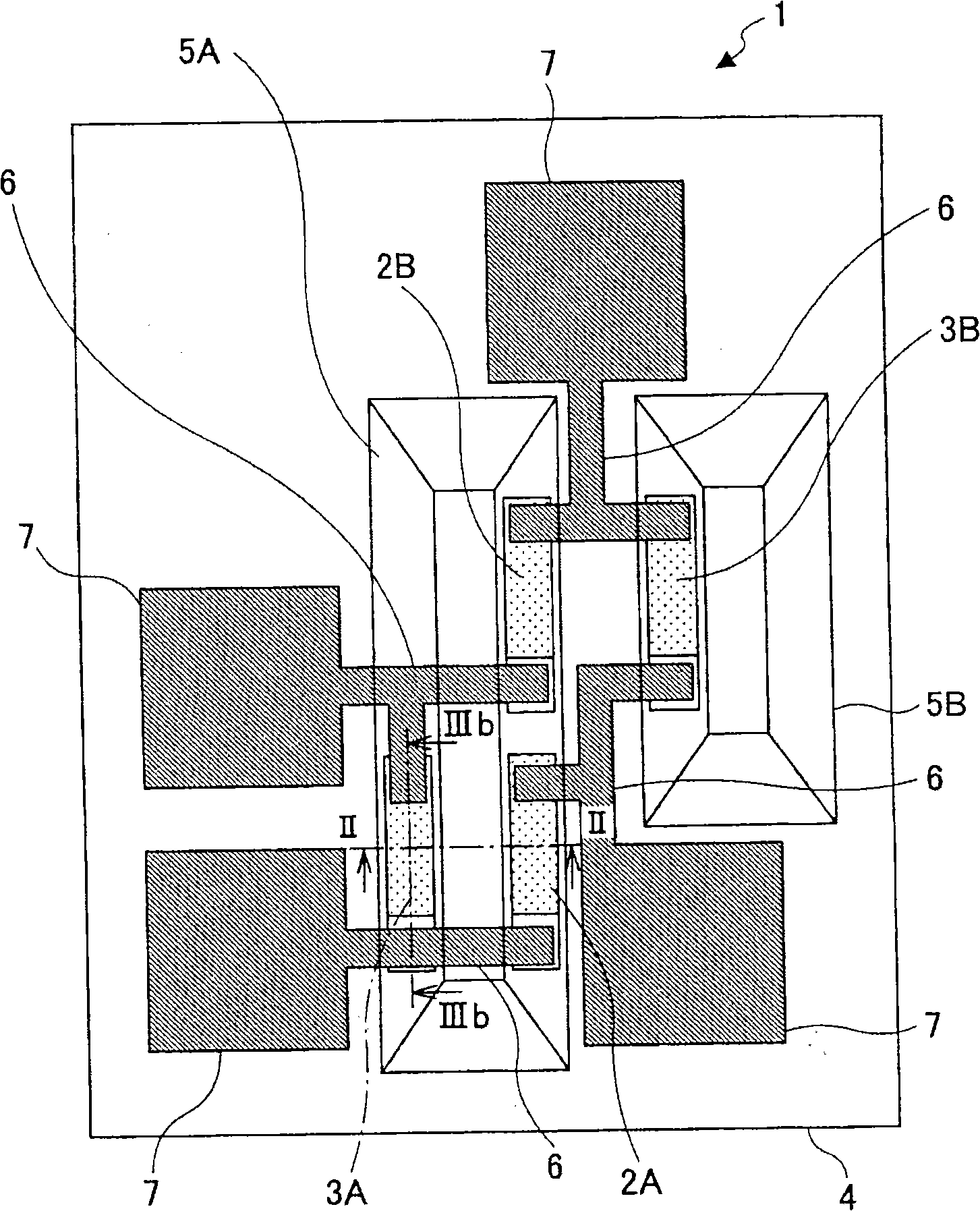

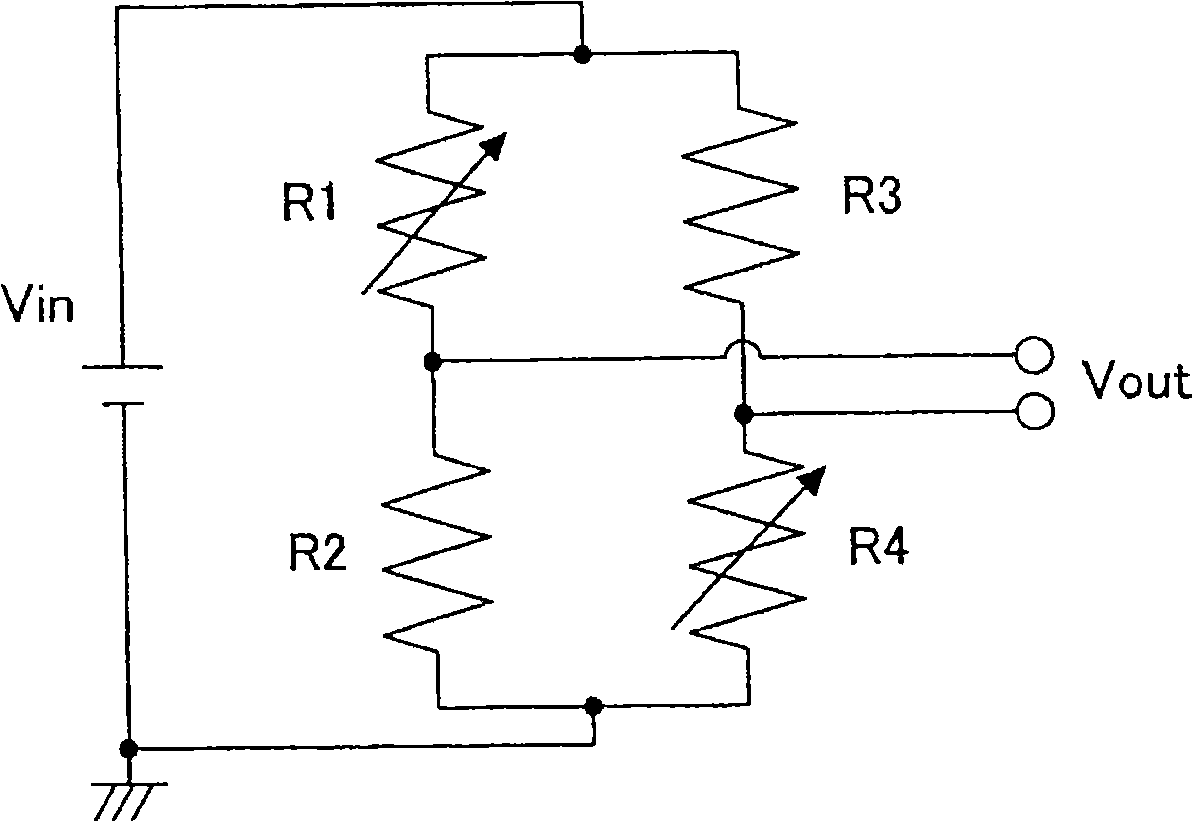

[0103] figure 1 It is a plan view schematically showing the configuration of the magnetic sensor according to the first embodiment in which magnetoresistance effect elements are connected to form a bridge circuit.

[0104] Such as figure 1 As shown, the magnetic sensor 1 of the present embodiment includes a substrate 4; a magnetic field detector 2A, a magnetic field detector 2B, a fixed resistor 3A, and a fixed resistor 3B arranged on the substrate 4; slots 5A and 5B (collectively referred to as “groove 5 ”); connection wiring 6 ; and bonding pad 7 .

[0105] For example, the magnetic field detectors 2A and 2B and the fixed resistors 3A and 3B are tunneling magnetoresistive (TMR) elements. Furthermore, the magnetic field detectors 2A and 2B and the fixed resistors 3A and 3B have the same layer configuration. In each of the fixed resistors 3A and 3B, a m...

no. 2 example

[0144] Similar to the first embodiment, in this embodiment, the magnetic field detectors are arranged in the same inclined surface with a certain angle.

[0145] Figure 6 A plan view schematically showing the configuration of a magnetic sensor according to a second embodiment in which magnetoresistance effect elements are connected to form a bridge circuit.

[0146] Such as Figure 6 As shown, the magnetic sensor 301 of this embodiment includes a substrate 304; a magnetic field detector 302A, a magnetic field detector 302B, a fixed resistor 303A, and a fixed resistor 303B arranged on the substrate 304; a groove 305; a connection wiring 306; and a bonding pad 307.

[0147] In the magnetic sensor 301, the fixed resistor 303A and the fixed resistor 303B are arranged on the same surface on which the bonding pad 307 is formed.

[0148] Here, for example, the magnetic field detectors 302A and 302B and the fixed resistors 303A and 303B are tunneling magnetoresistive (TMR) element...

no. 3 example

[0164] In this embodiment, the magnetic field detector and the fixed resistor are arranged in the inclined surface of the same slot.

[0165] Figure 8 A plan view schematically showing the configuration of a magnetic sensor according to a third embodiment in which magnetoresistance effect elements are connected to form a bridge circuit.

[0166] Figure 9 along Figure 8 Sectional view of line XVII-XVII.

[0167] Such as Figure 8 As shown, the magnetic sensor 401 of this embodiment includes a substrate 404; a magnetic field detector 402A, a magnetic field detector 402B, a fixed resistor 403A, and a fixed resistor 403B arranged on the substrate 404; a groove 405; a connecting wiring 406; and a bonding pad 407.

[0168] In the magnetic sensor 401 , a magnetic field detector 402A, a magnetic field detector 402B, a fixed resistor 403A, and a fixed resistor 403B are arranged within the inclined surface of the same groove 405 .

[0169] Here, for example, the magnetic field ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com