Power supply system for minisize composite regenerative fuel battery

A fuel cell and power system technology, which is applied in the direction of regenerative fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of microporous membrane flooding, increased gas transmission resistance, etc., and achieve stable output power and cycle operation performance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Prepare materials and components

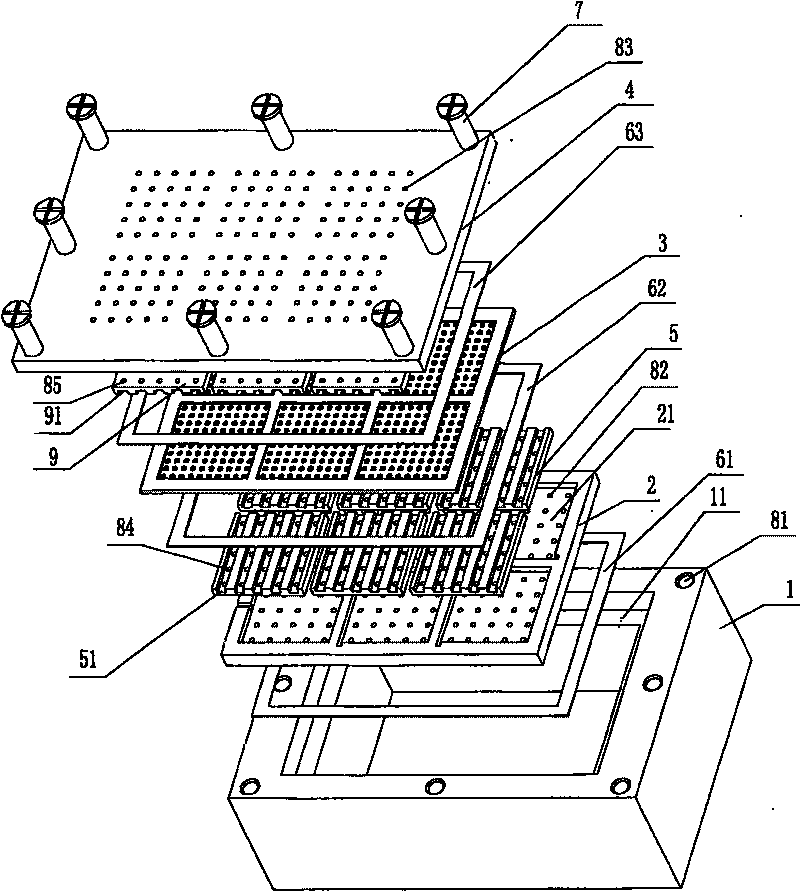

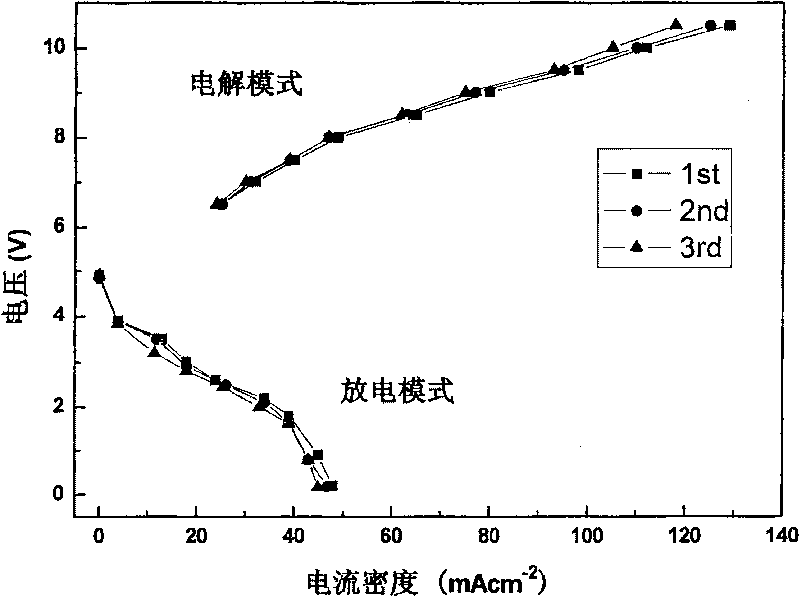

[0047] In the membrane electrode assembly shown, Nafion112 membrane is used as the proton exchange membrane, and the area of a single electrode is 1cm×1cm, and the distance between them is 1mm; Johnson Matthey 40% Pt / C catalyst is used for both cathode and anode, and the anode Pt loading is 0.6mg / cm 2 , the cathode Pt loading is 0.8mg / cm 2 ; Hydrogen storage material with 10 grams of LaNi 5 Alloy powder, use degreasing sponge as water-retaining material, add about 10ml of water; hydrophilic carbon paper without polytetrafluoroethylene (PTFE) treatment and hydrophobic carbon paper with PTFE content of 15% are used as the diffusion of anode and cathode respectively The positive and negative pole plates are made of graphite, with a size of 1cm×1cm; fine platinum wire is used as the plate wire; the bottom box, bottom plate, and top cover are all made of plexiglass material, and the size is comparable to that of the membrane electr...

Embodiment 2

[0051] (1) Prepare materials and components

[0052] Both cathode and anode catalysts use TANAKA 50% Pt / C catalyst, and other materials and components are the same as in Example 1.

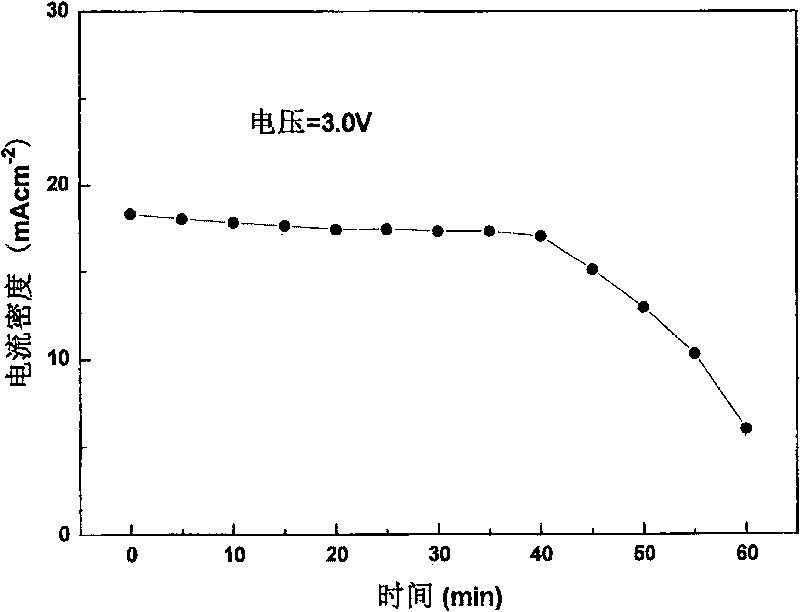

[0053] (2) Assembly test

[0054] Assembled with embodiment 1. First operate in electrolysis mode with a voltage of 9.3V for 2 hours, then switch to fuel cell mode to test its constant voltage discharge performance at 3.0V, the performance curve is as follows image 3 shown. It can be seen from the figure that at a constant voltage of 3.0V, the current density can be maintained at about 18mA cm -2 Continue to discharge for about 40 minutes.

Embodiment 3

[0056] (1) Prepare materials and components

[0057] Both cathode and anode catalysts use 20% Pt / CNT catalysts, and other materials and parts are the same as in Example 1.

[0058] (2) Assembly test

[0059] Assembled with embodiment 1. Firstly operate in electrolysis mode with a voltage of 8.6V for 2 hours, and then switch to fuel cell mode to test its temperature at 10mA cm -2 Constant current discharge performance under current density; recirculate once, test it at 20mA·cm -2 The constant current discharge performance under the current density, the performance curve is as follows Figure 4 shown. It can be seen from the figure that at 10mA·cm -2 Under the current density, it can maintain the voltage of 3.6V for about 50 minutes; at 20mA·cm -2 Under the current density, the voltage of 2.9V can be maintained for about 25 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com