Sinusoidal angled rotary cutting tool

A tool and cutting edge technology, applied in the field of low-resonance end mills, can solve the problem of weakening shear force in local areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

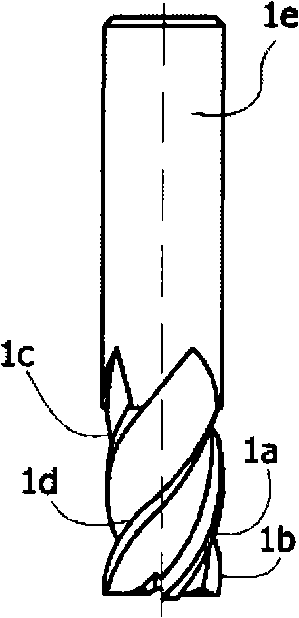

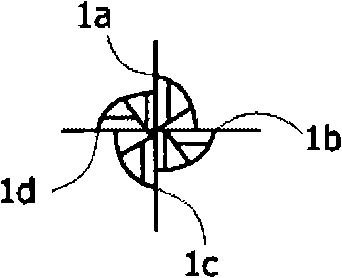

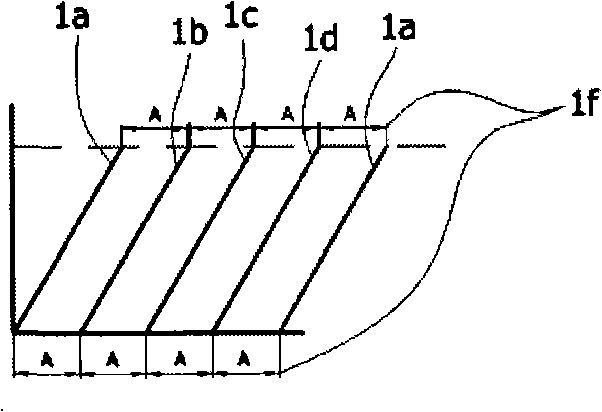

[0052] Figure 5A to Figure 5C An end mill having four cutting edges according to a first embodiment of the present disclosure is shown. The end mill has sinusoidal cutting edges equally spaced around the circumference of the cutting surface.

[0053] The end mill comprises a cylindrical tool body 100 having a longitudinal central axis 101 . The end mill in this preferred embodiment can be used, for example, in the precision machining industry. The end mill includes a single fluted cutting end 102 oppositely formed on a cylindrical body and a shank end 5e having a shank extending along a longitudinal central axis. Those of ordinary skill in the art will appreciate that while a flat nose end mill (i.e., an end mill with a flat end cutting surface) is shown, any other end is possible, such as a spherical end, ball nose, Countersunk end (chamfer end) and so on. The disclosed end mills are also not limited to cutting a single type of material. This preferred embodiment can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com