Method for preventing and treating blue mold contamination in starter propagation of sauce

A technology for Penicillium spp. and soy sauce is applied in the field of condiments to achieve the effects of preventing musty odor, improving flavor quality and food safety performance, and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

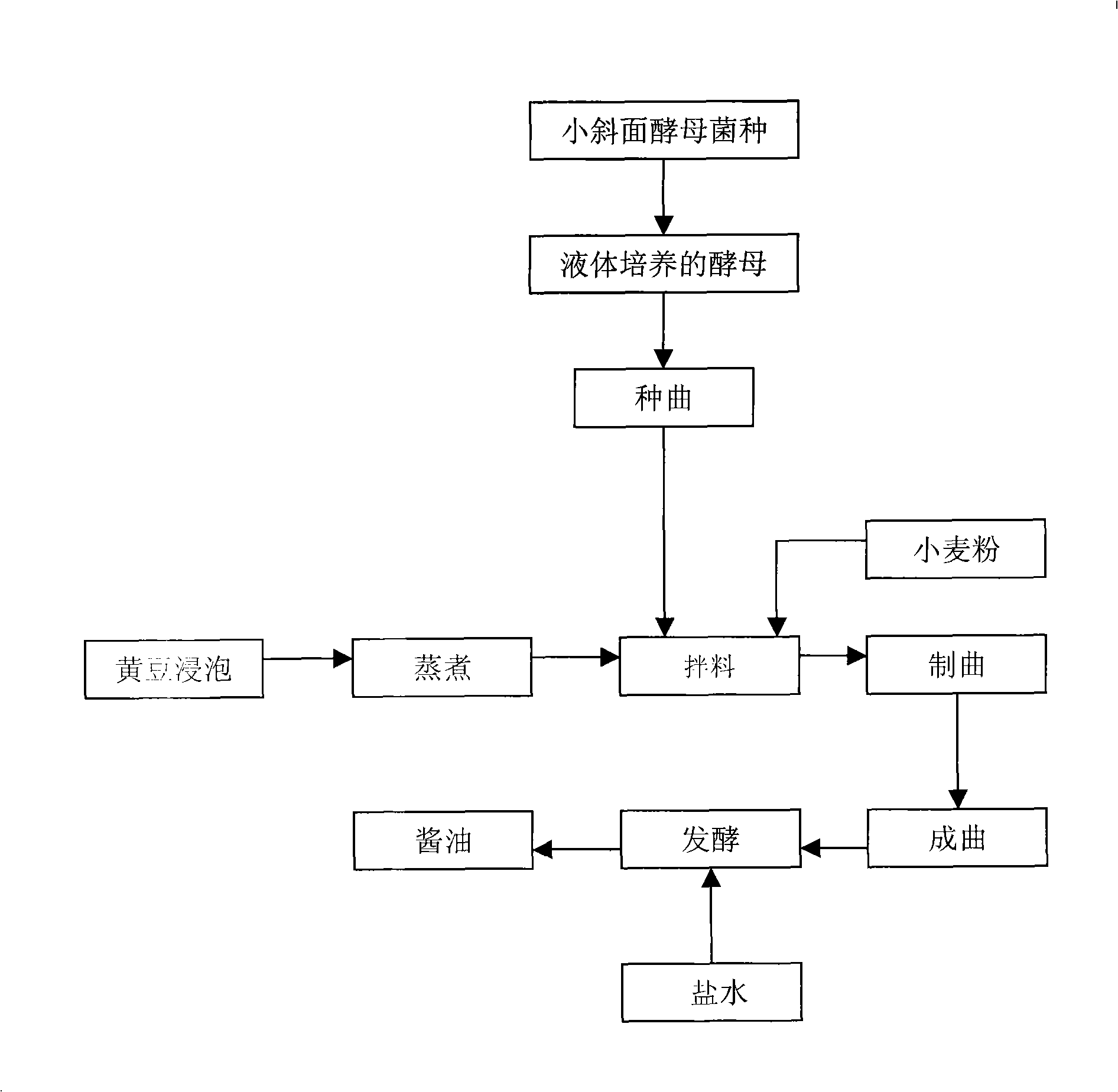

[0024] The production process of bean koji soy sauce is as follows: figure 1 As shown, the factory production and use are carried out according to the koji making process, and the operations of koji making and fermentation are all carried out according to conventional production operations. The inoculum size of antagonistic yeast was 10 3 ~10 7 Individual / g, the antagonistic yeast can produce antagonistic inhibitory effect on Penicillium in koji making while multiplying.

[0025] The antagonistic yeast strain Candida Tropicalis used is isolated from koji-making materials by conventional plate separation methods; after liquid expansion culture, it is mixed with Aspergillus koji and added to bean koji.

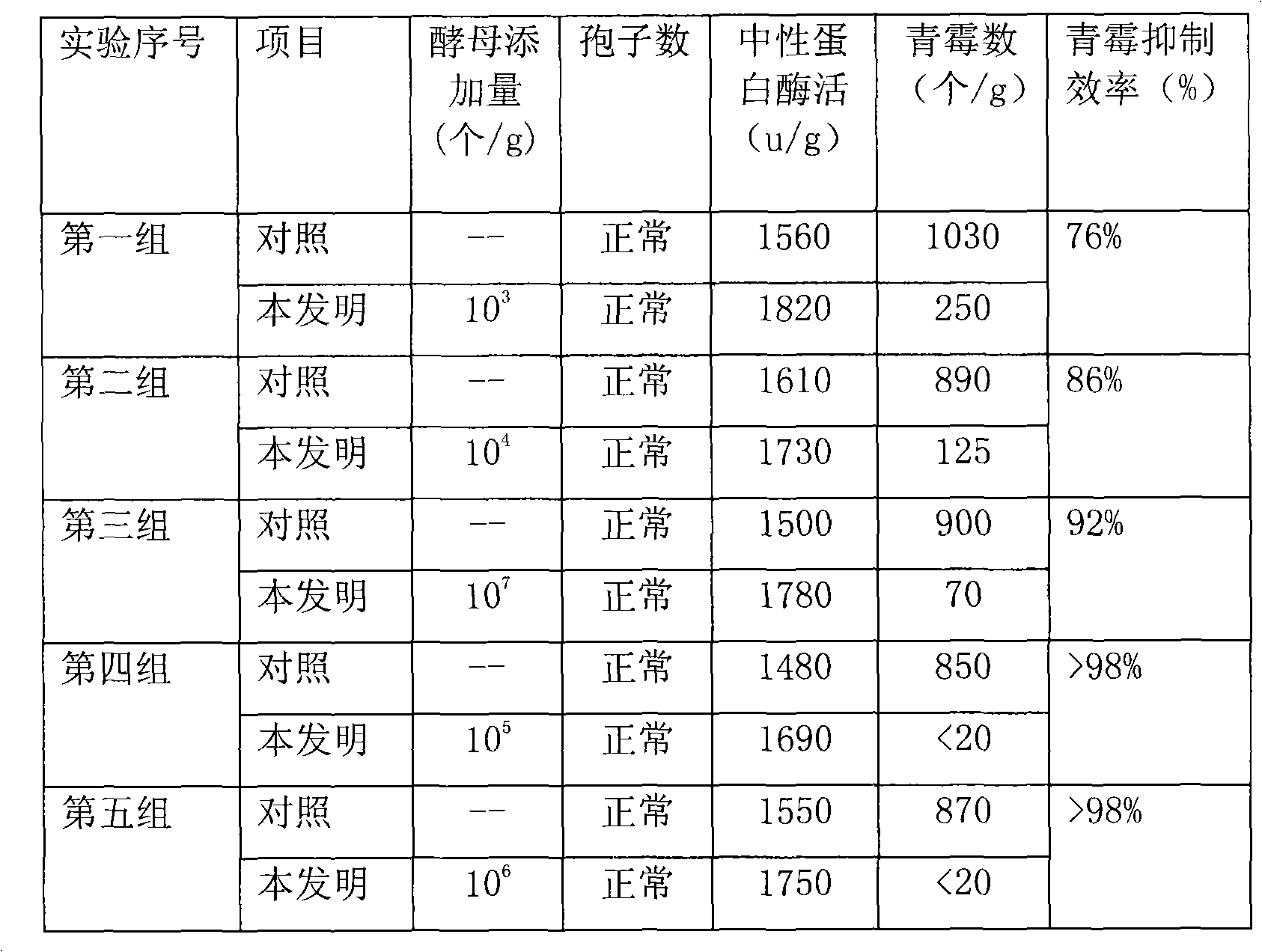

[0026] According to the bean koji production process, the koji was made 5 times in total, and the control samples with antagonistic yeast and no yeast were made at the same time each time. After the koji was formed, the koji quality and Penicillium inhibition efficiency were ...

Embodiment 2

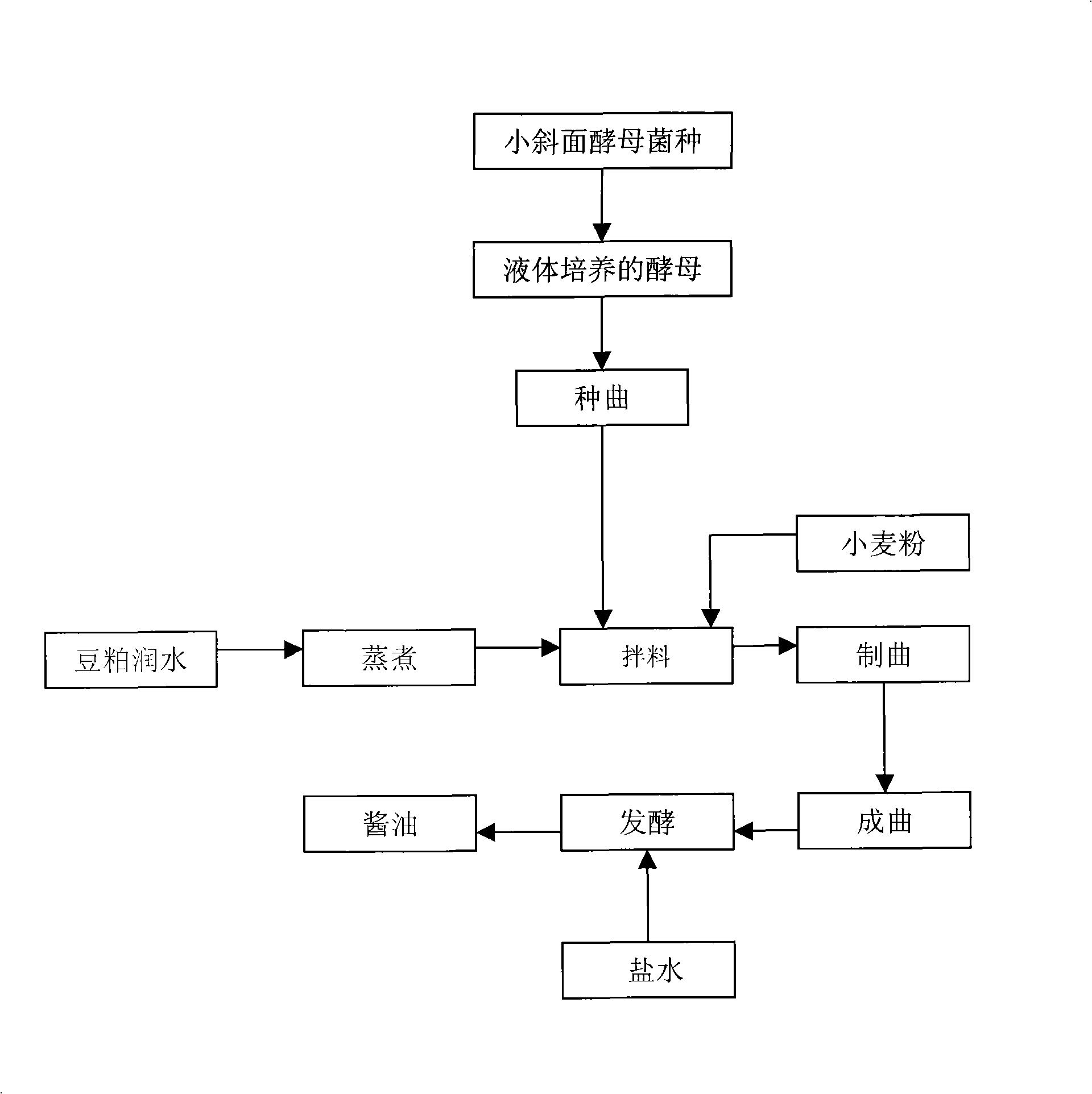

[0037] The production process of gluten soy sauce is as follows: figure 2 As shown, the factory production and use are carried out according to the koji making process, and the operations of koji making and fermentation are all carried out according to conventional production operations. The inoculation amount of antagonistic yeast is 10-10 4 Individual / g, the antagonistic yeast can produce antagonistic inhibitory effect on Penicillium in koji making while multiplying.

[0038] The antagonistic yeast strain Candida Tropicalis used is isolated from the koji-making material by a conventional plate separation method; after liquid expansion culture, it is mixed with Aspergillus koji and then added to bran koji.

[0039] According to the production process of bran koji, the koji was made 5 times in total, and the control samples with antagonistic yeast and no yeast were made at the same time each time. After the koji was formed, the koji quality and Penicillium inhibition effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com