Synthetic method of m-amino acetanilide

A technology for the synthesis of aminoacetanilide and its synthesis method, which is applied in the field of synthesis of m-aminoacetanilide, can solve the problems of long cycle, high energy consumption, and cumbersome steps, and achieve the effects of short production cycle, low energy consumption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

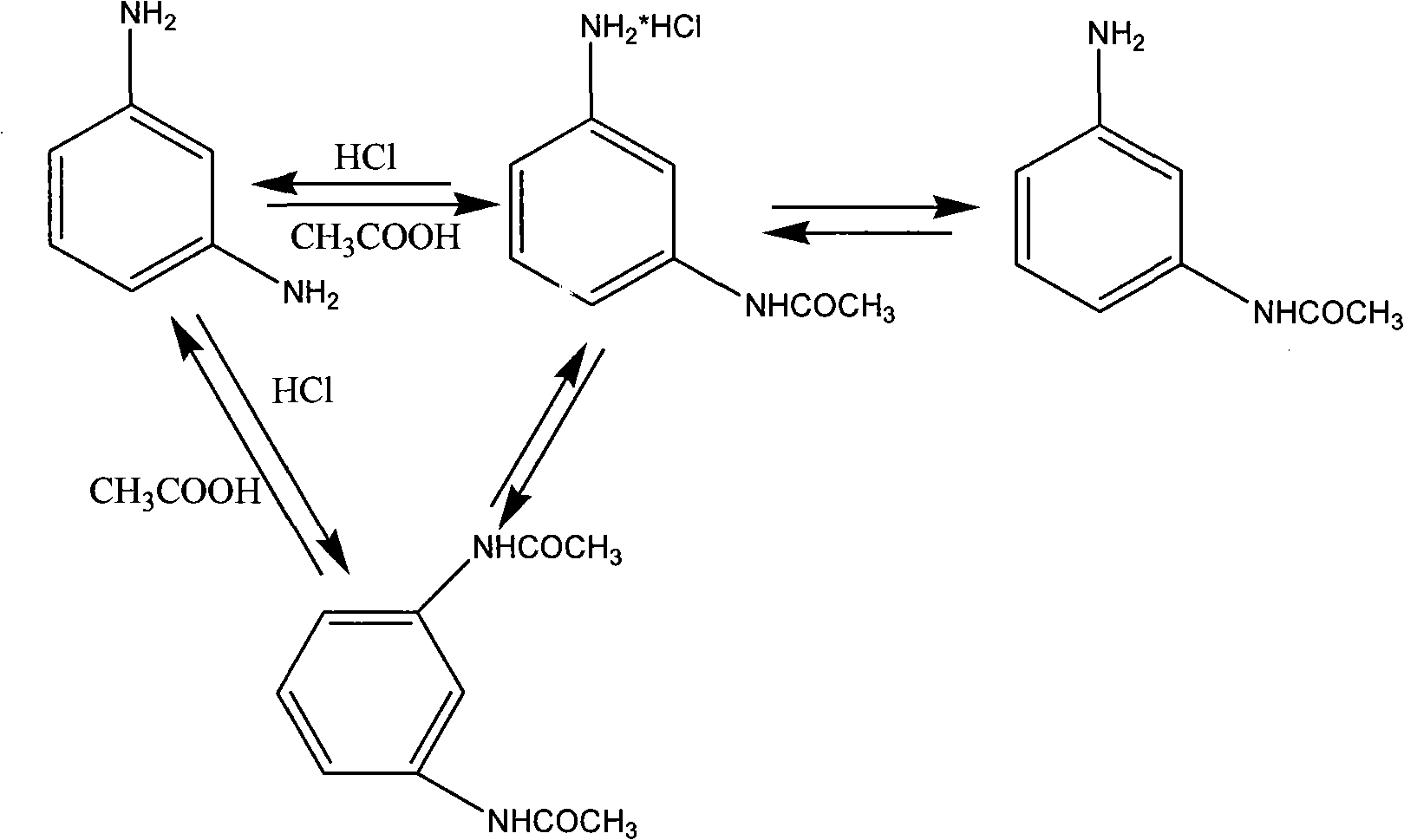

Method used

Image

Examples

Embodiment 1

[0022] Get m-acetamidoaniline mother liquor 660g, wherein contain: hydrochloric acid 33g, acetic acid 59.4g, m-acetamidoaniline 30g, m-phenylenediamine 50g, m-diacetamidoaniline 60g, pass into HCl gas 30g by differential method at normal temperature, Add 88g of m-phenylenediamine and 56g of glacial acetic acid (percentage), heat up to 96-104°C and react for 20h, cool down to below 35°C and filter, drain the obtained filter cake, add 20g of water to wash, and obtain a purity of 99 % m-acetamido aniline, washing liquid and mother liquor mix about 680g, as the mother liquor of applying mechanically next time.

Embodiment 2

[0024] Take 660g of mother liquor, which contains: 59.4g of hydrochloric acid, 105g of acetic acid, 44g of m-phenylenediamine, 80g of m-phenylenediamine, 25g of HCl gas by differential method at normal temperature, and add m-phenylenediline 88 g of amine and 56 g of glacial acetic acid (100 percent), heated up to 96-104 ° C for 20 hours, cooled to below 35 ° C and filtered, after the obtained filter cake was drained, 30 g of water was added to wash, and the purity of 99% m-acetyl Aminoaniline, lotion and mother liquor mix about 690g, as the mother liquor of applying mechanically next time.

Embodiment 3

[0026] Get the lotion that obtains of embodiment 2 and mother liquor 690g, wherein contain: hydrochloric acid 45.4g, acetic acid 75g, m-acetamidoaniline 40g, m-phenylenediamine 60g, m-diacetamidoaniline 70g, pass through differential method at normal temperature Add 28g of HCl gas, add 88g of m-phenylenediamine and 28g of acetic anhydride (100%), heat up to 110-118°C and react for 18h, cool down to below 35°C and filter, drain the obtained filter cake, add 25g of water to wash , to obtain a purity of 99% m-acetaminoaniline, washing liquid and mother liquor mixed about 690g, as the next time the mother liquor.

[0027] Analysis shows that adopting the process of the invention can not only simplify operation and save energy, but also has no slight influence on the purity of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com