Dual rotors translation type rotary compressing device

A rotary compression and translational technology, applied in rotary piston pumps, rotary piston machines, components of pumping devices for elastic fluids, etc. Large volume, poor heat dissipation performance and other problems, to achieve the effect of improving heat dissipation effect, improving cooling system and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

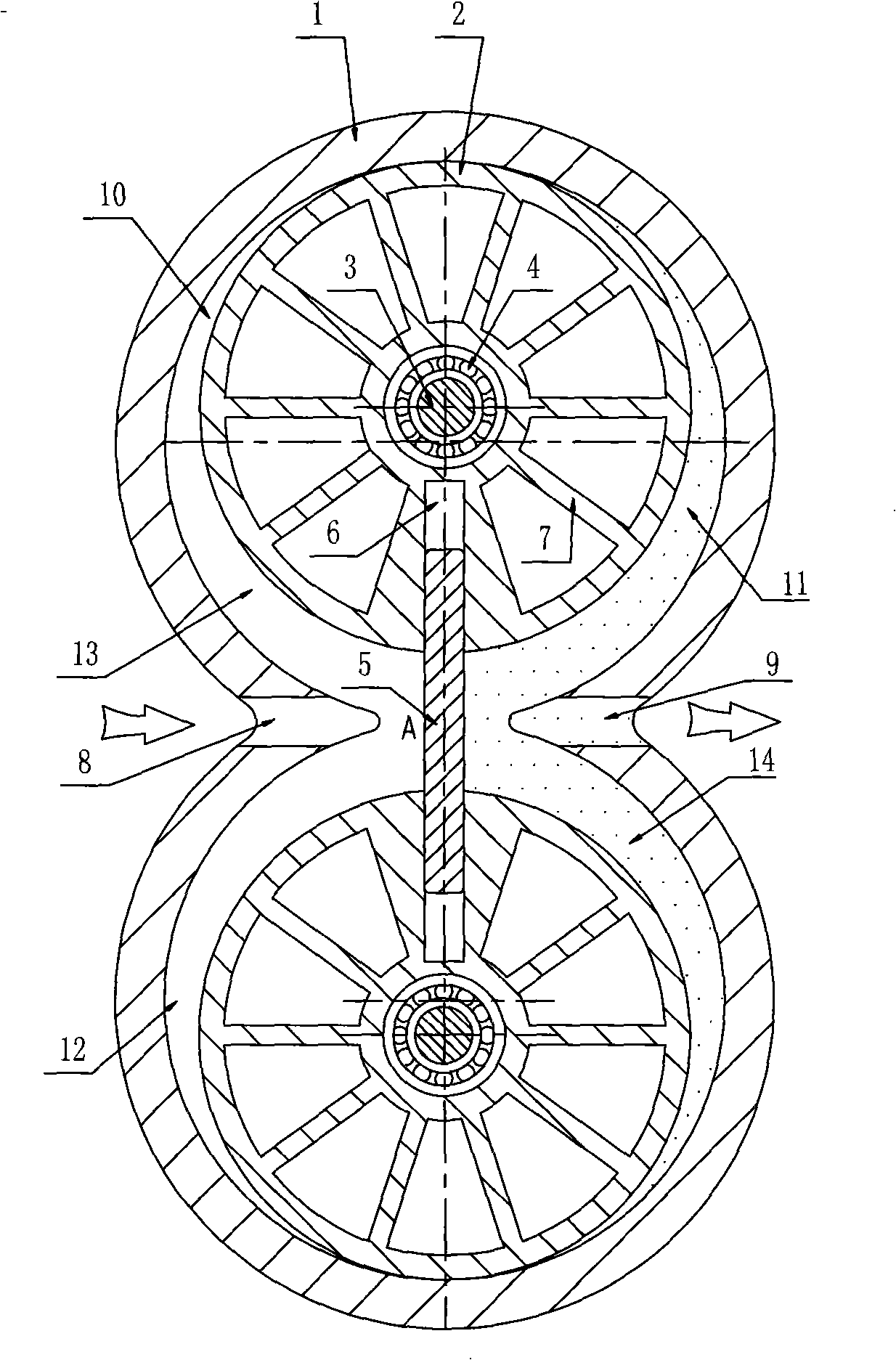

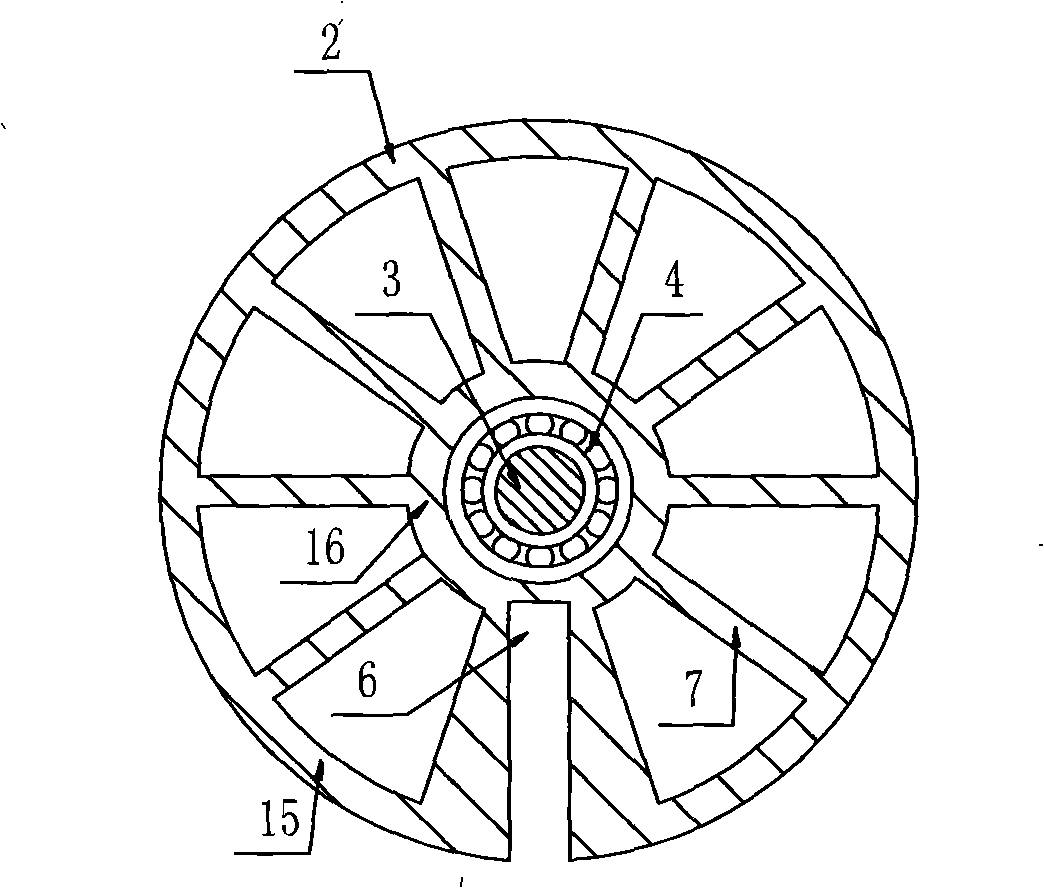

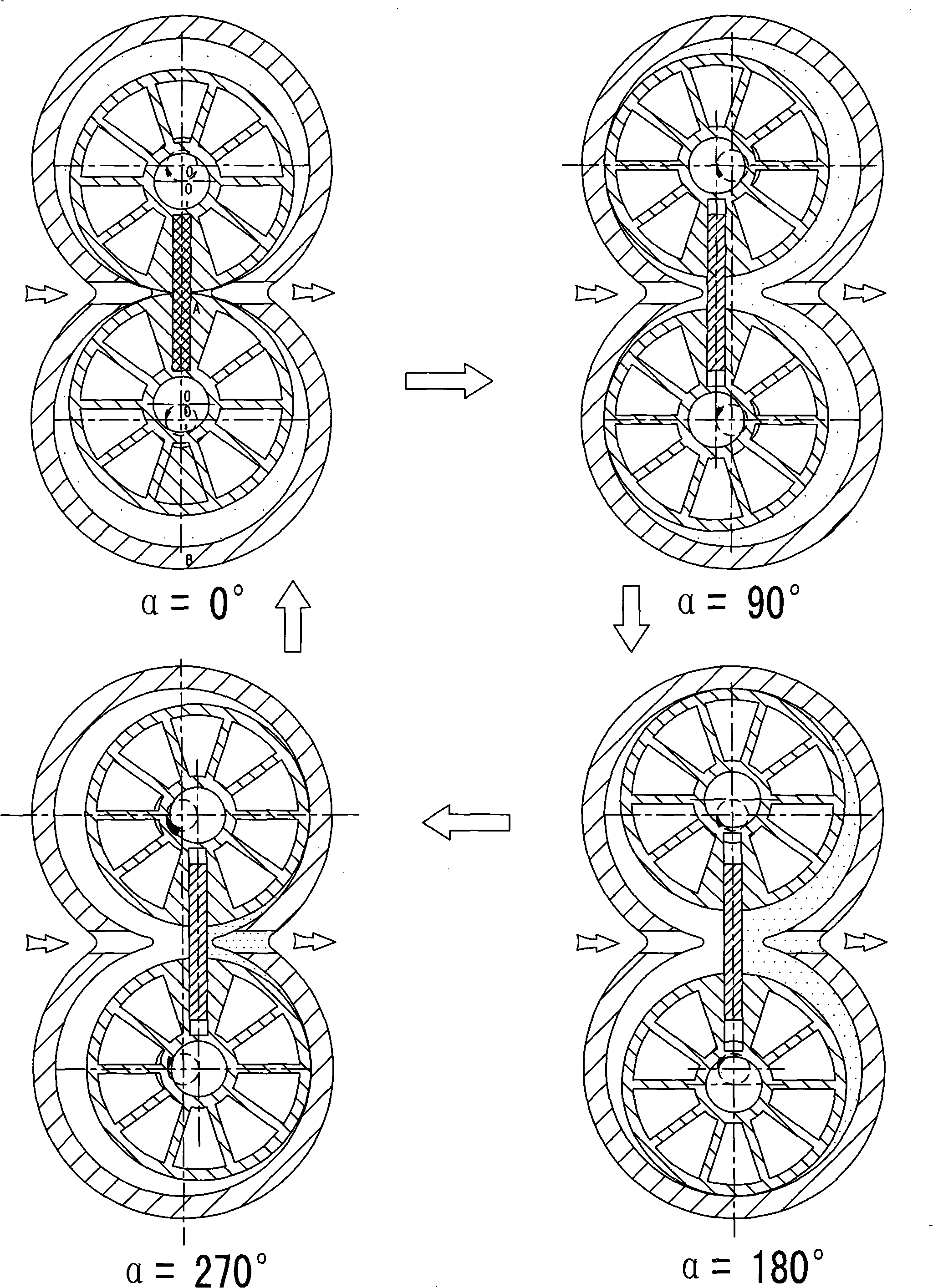

[0023] Such as figure 1 The shown double-rotor translational rotary compression device includes a cylinder 1 and two translational pistons 2. The interior of the cylinder 1 includes two circular through holes 10, and the joints of the two through holes 10 are connected to each other. Tong, forming an "8"-shaped studio, the outer ring of the cylinder body 1 is provided with a number of cooling fins. Synchronously rotating eccentric rotors 3 are respectively arranged in the two through holes 10. The rotation center of the eccentric rotor 3 is concentric with the through holes 10. Two translation pistons 2 are respectively arranged on the eccentric rotor 3. The translation piston 2 and the eccentric rotor 3 are connected by rolling bearing 4. The outer surface of the translational piston 2 is kept tangent to the inner surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com