Four-way valve bypass defrosting device

A four-way valve and one-way valve technology, used in damage protection, refrigeration components, refrigerators, etc., can solve the problems of high cost of solenoid valves, difficult oil return to the system, affecting heating performance, etc., to ensure reliability and stability. performance, improve the overall energy efficiency ratio, and increase the effect of heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

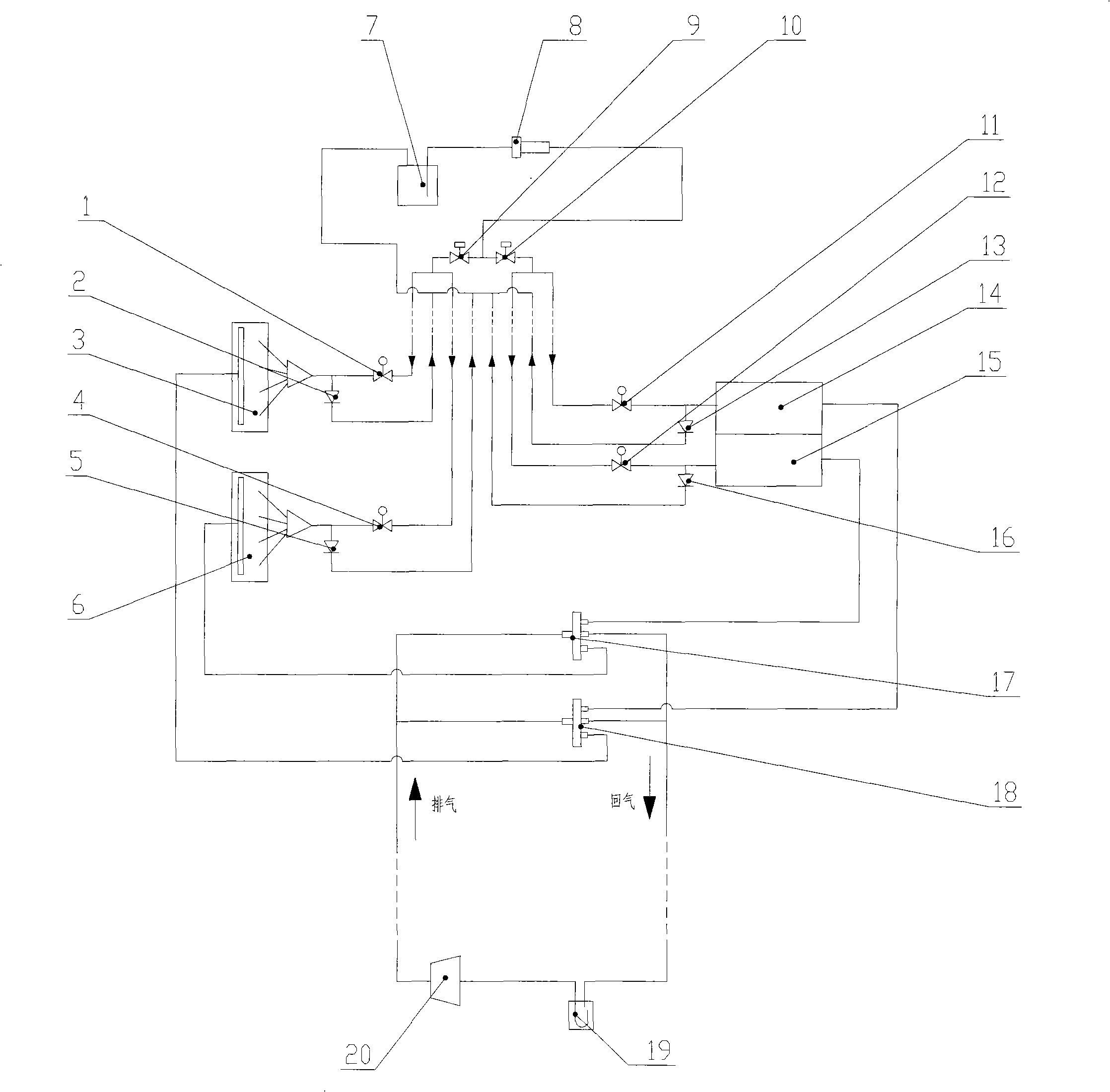

[0016] figure 1 It is a structural schematic diagram of a four-way valve bypass defrosting device of the present invention. In this embodiment, the principles of the present invention are specifically described by taking the four-way valve, the heat exchange assembly on the condensation side, and the heat exchange assembly on the air side as two groups as an example.

[0017] The four-way valve bypass defrosting device includes a compressor 20, a gas-liquid separator 19, a high-pressure liquid reservoir 7, a first four-way valve 17, a second four-way valve 18, a filter 8, and an air side solenoid valve 9 , a solenoid valve 10 on the condensation side, two sets of heat exchange components on the condensation side and two sets of heat exchange components on the air side. The exhaust port of the compressor 20 is connected with the first ports of the first four-way valve 17 and the second four-way valve 18, and the second ports of the first four-way valve 17 and the second four-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com