Microstructure optical fiber sensing probe

A technology of microstructure optical fiber and sensing probe, which is applied in the field of sensing probe, can solve the problems of unfavorable probe miniaturization, long length of optical fiber probe, etc., and achieve the effect of increasing effective contact area, not easy to break, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

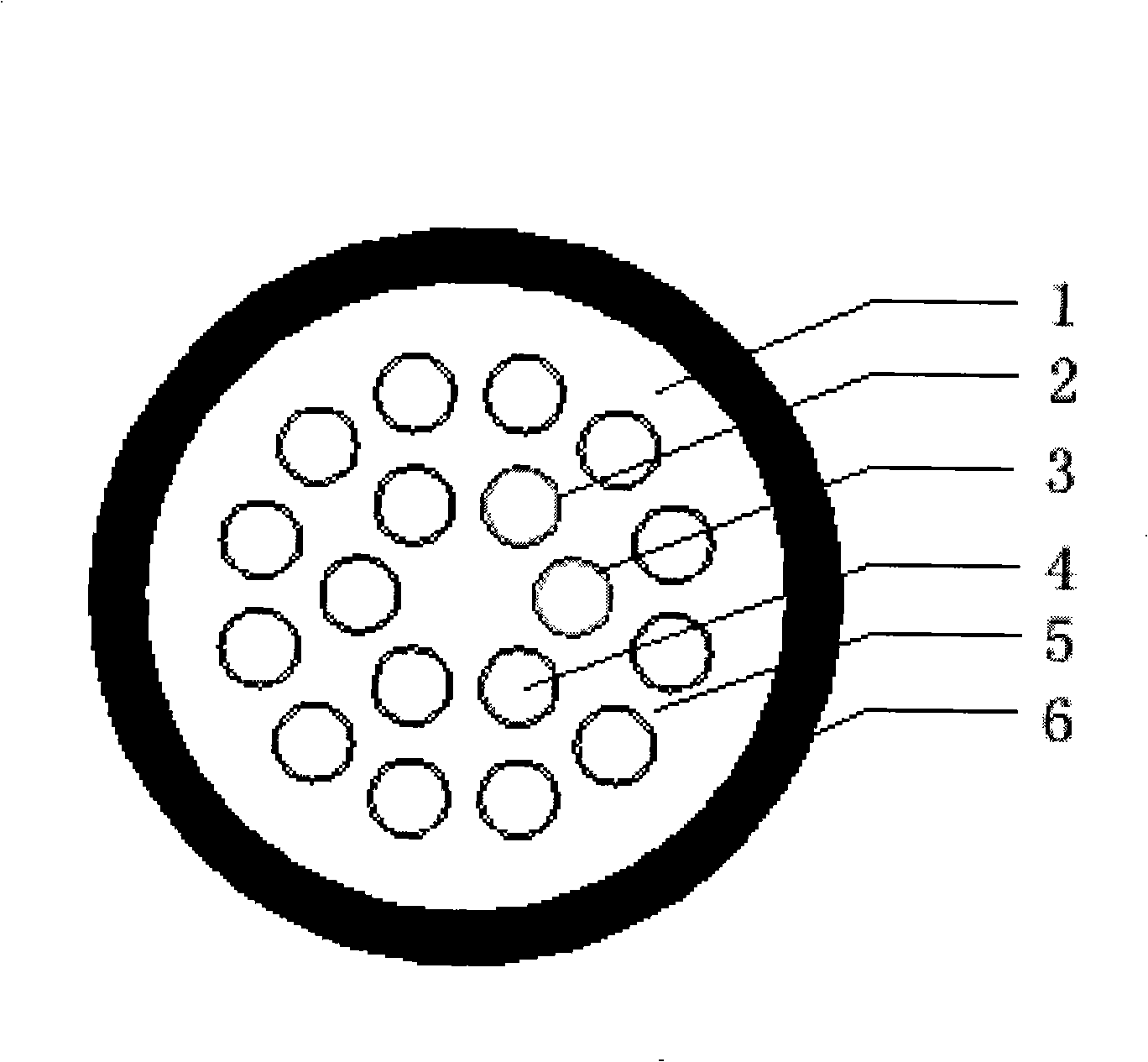

[0016] see figure 1 , the present invention comprises an optical fiber matrix 1, an inner cladding 5 and an outer cladding 6, the optical fiber matrix 1 is arranged in the outer cladding 6, the inner cladding 5 is arranged in the optical fiber matrix 1, the inner cladding 5 is composed of a tunnel 2, and the inner surface of the tunnel 2 is arranged There is a sensing layer 3 . There are one or more tunnels 2, and when there are multiple tunnels 2, the inner cladding 5 is composed of periodically distributed tunnels 2 with characteristics of microstructured optical fibers. The material of the optical fiber matrix 1 is polymethyl methacrylate, polystyrene or polycarbonate. The sensing layers 3 on the inner surfaces of different pores 2 can be modified with the same specific molecules or antibodies, or can be modified with different specific molecules or antibodies. The sensing layer 3 on the inner surface of different channels 2 is modified with the same specific molecule or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com