Sensor for measuring gas water content

A sensor and water content technology, which is applied in the field of sensors and sensors for measuring the water content of gas, can solve the problems of long measurement time and inconvenient use, and achieve the effects of stable measurement data, easy disassembly and replacement, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

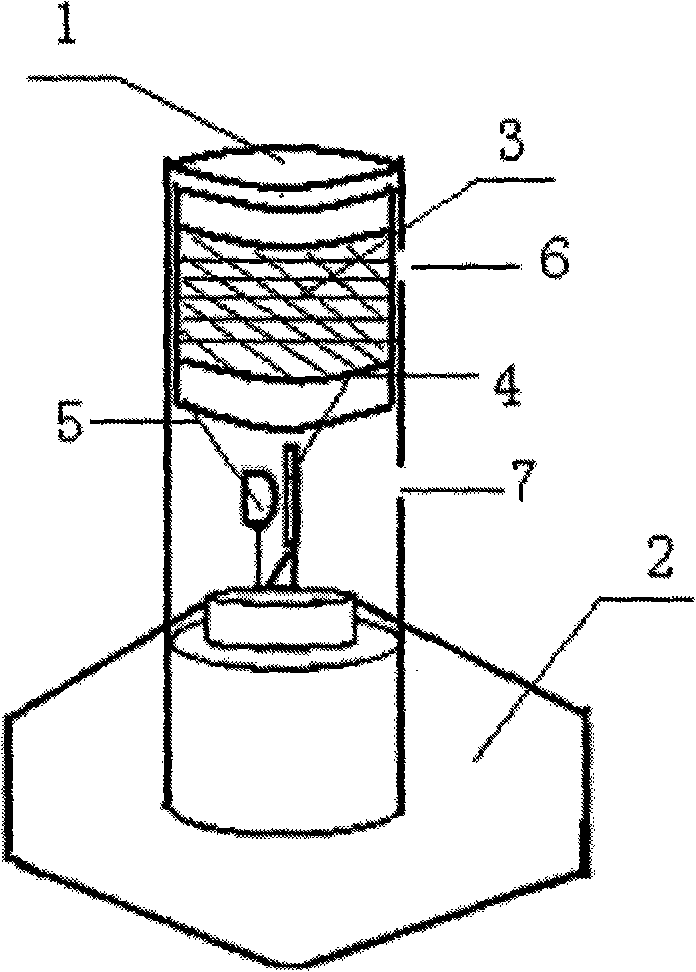

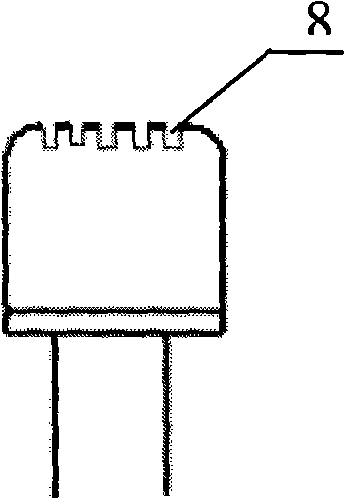

[0019] Such as figure 1 , 2 As shown, the sensor for measuring the water content of gas provided in this embodiment includes an air chamber 1, a base 2, a filter screen 3, a crystal oscillator 4, and a three-stage amplifier tube 5; the air chamber 1 is a cylinder with an inner hollow, The air chamber 1 is movably connected to the base 2 (the movably connected can be screwed, clamped, or screwed), the base 2 is provided with a crystal oscillator 4, a three-stage amplifier tube 5, and the crystal oscillator 4 and the three-stage amplifier tube 5 connection, the air chamber 1 is provided with an air inlet 6 and an air outlet 7, and the air chamber 1 is provided with a filter 3, the filter 3 is a cylinder, and the filter 3 is fully in contact with the air chamber 1; the crystal oscillator 4 A layer of hydrophilic film is attached to the inner wall, and several holes 8 are opened on the top of the crystal oscillator 4 .

[0020] Open the top of the crystal oscillator 4, and attac...

Embodiment 2

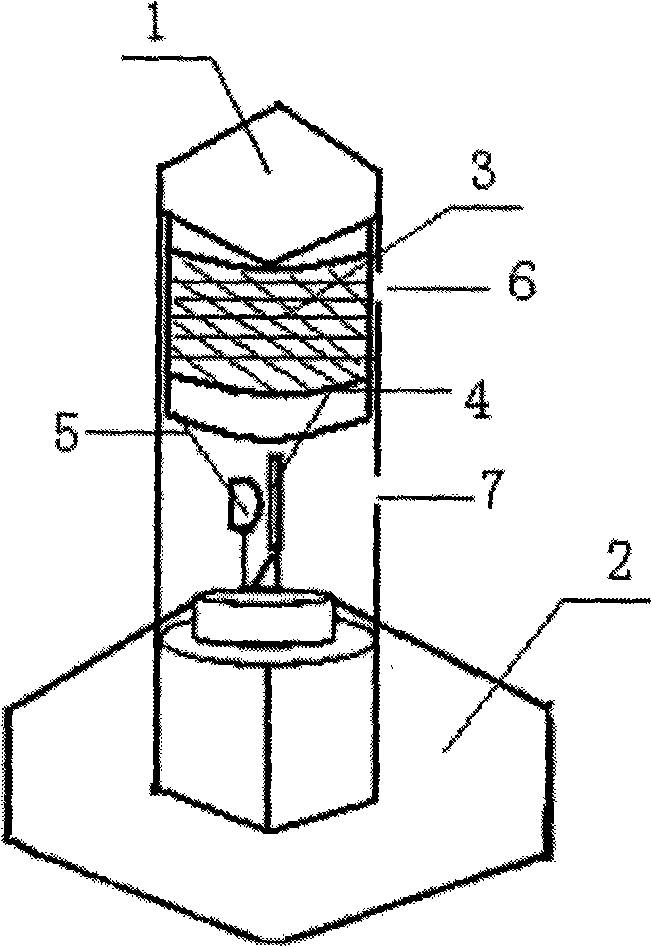

[0022] Such as figure 2 , 3 , 4, and 5, the sensor for measuring the water content of gas provided in this embodiment includes an air chamber 1, a base 2, a filter screen 3, a crystal oscillator 4, and a three-stage amplifier tube 5; the air chamber 1 is a hexagonal prism , the inner space is hollow, and its cut surface is a regular hexagon with an inscribed circle. The air chamber 1 is movably connected to the base 2 (the movably connected can be screwed, clamped, or connected with screws), and the base 2 is provided with Crystal oscillator 4, three-stage amplifying tube 5, crystal oscillator 4 is connected with three-stage amplifying tube 5, the air chamber 1 is provided with an air inlet 6 and an air outlet 7, and a filter screen 3 is provided in the air chamber 1, and the filter screen 3 is a cylinder body, the filter screen 3 is fully in contact with the air chamber 1; a layer of hydrophilic film is attached to the inner wall of the crystal oscillator 4, and several hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com