Plasma display device and method of driving PDP

A plasma and display device technology, applied in the field of plasma display devices, can solve problems such as image display quality deterioration, PDP misdischarge, etc., and achieve the effects of improving brightness and image display quality, reducing power consumption, and preventing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings showing exemplary embodiments of the present invention.

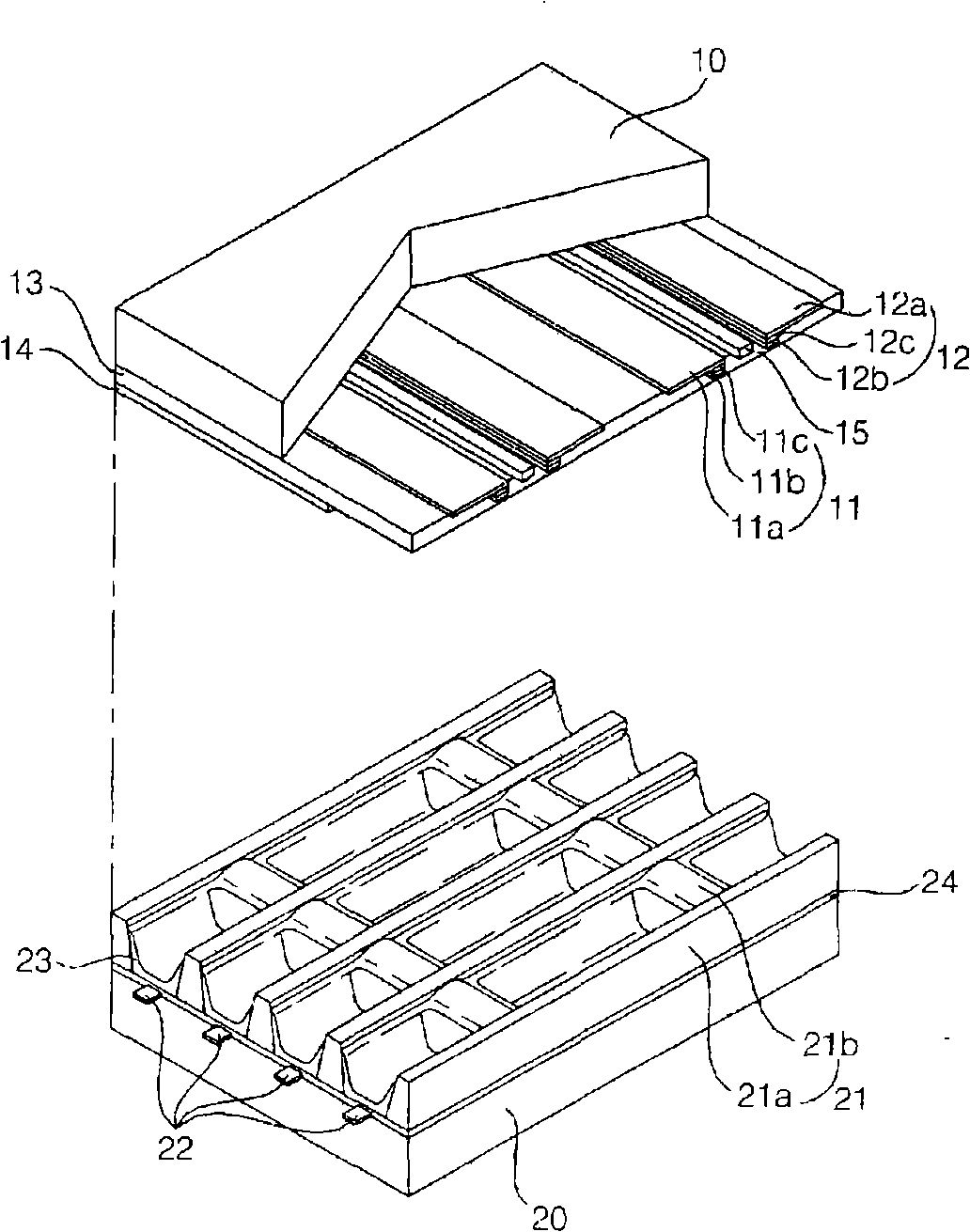

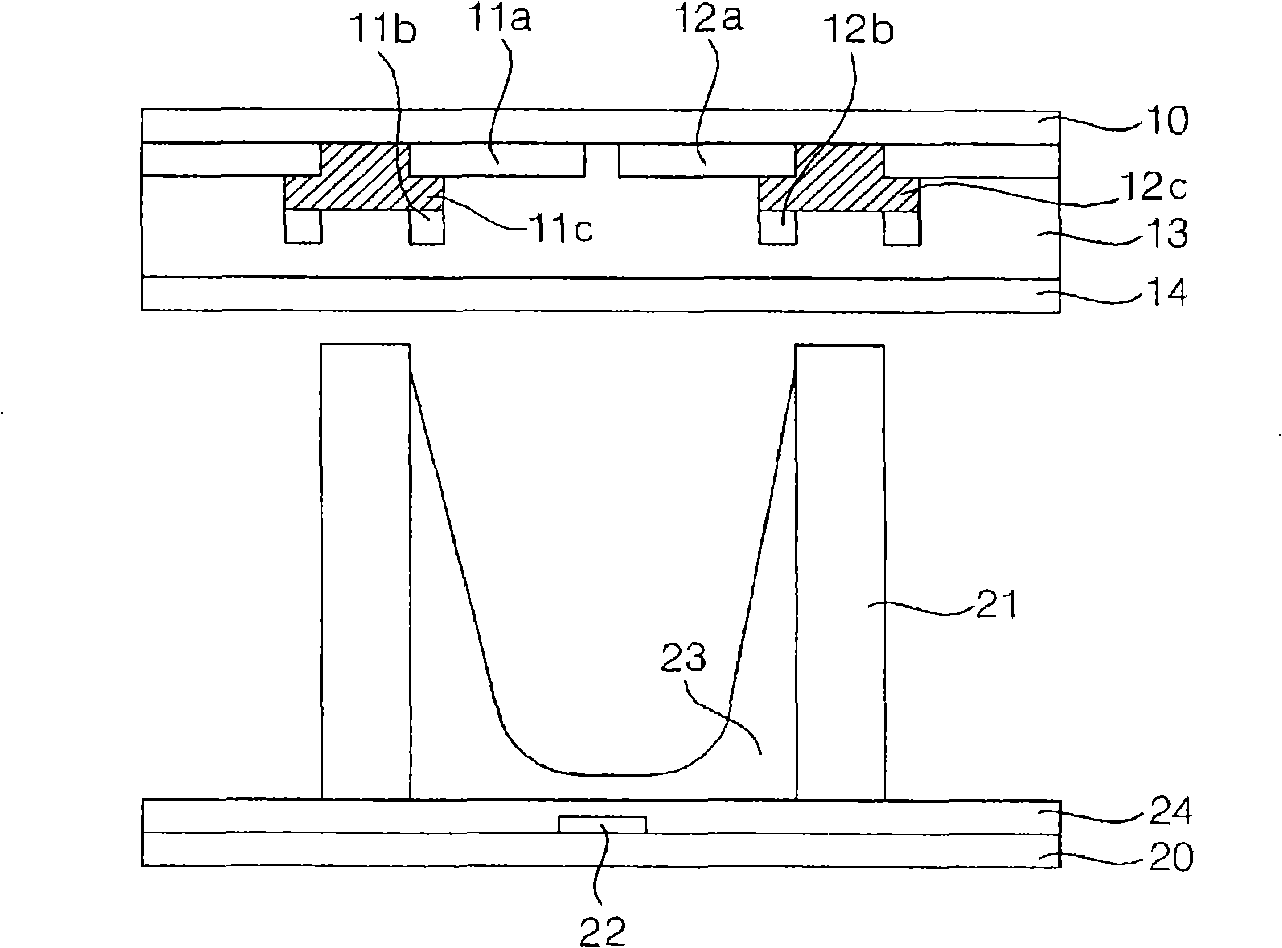

[0020] figure 1 It is a perspective view of a plasma display panel (PDP). refer to figure 1 , the PDP includes sustain electrode pairs formed on an upper substrate 10 and address electrodes 22 formed on a lower substrate 20 . The sustain electrode pair includes scan electrodes 11 and sustain electrodes 12 .

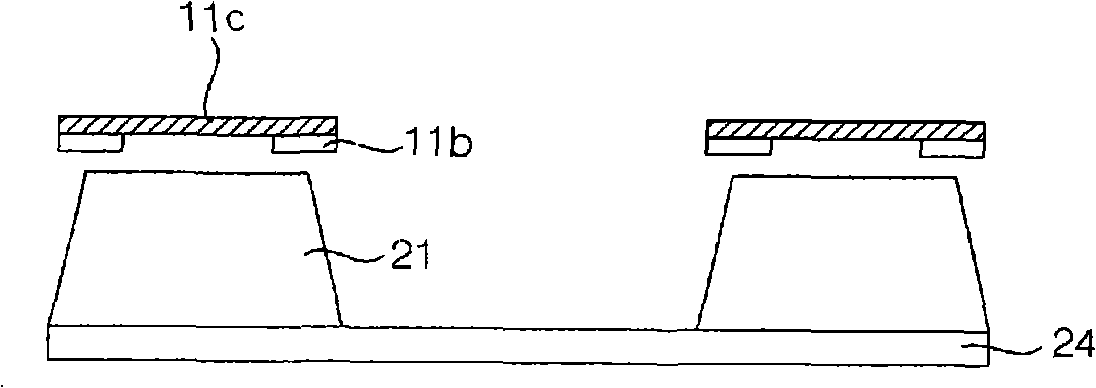

[0021] The scan electrode 11 may include a transparent electrode 11a and a bus electrode 11b, and the sustain electrode 12 may include a transparent electrode 12a and a bus electrode 12b. The transparent electrodes 11a and 12a may be formed using indium tin oxide (ITO). The bus electrodes 11b and 12b may be formed of a metal such as silver (Ag) or chromium (Cr), a chromium / copper / chromium (Cr / Cu / Cr) stack, or a chromium / aluminum / chromium (Cr / Al / Cr) stack. . The bus electrodes 11b and 12b are dispo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com