Combined speed reducer for stir can

A reducer and meshing technology, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of uneven mixing and difficulty in meeting the mixing requirements of high-quality mortar, and achieve improved mixing uniformity, compact structure, Avoid easy loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

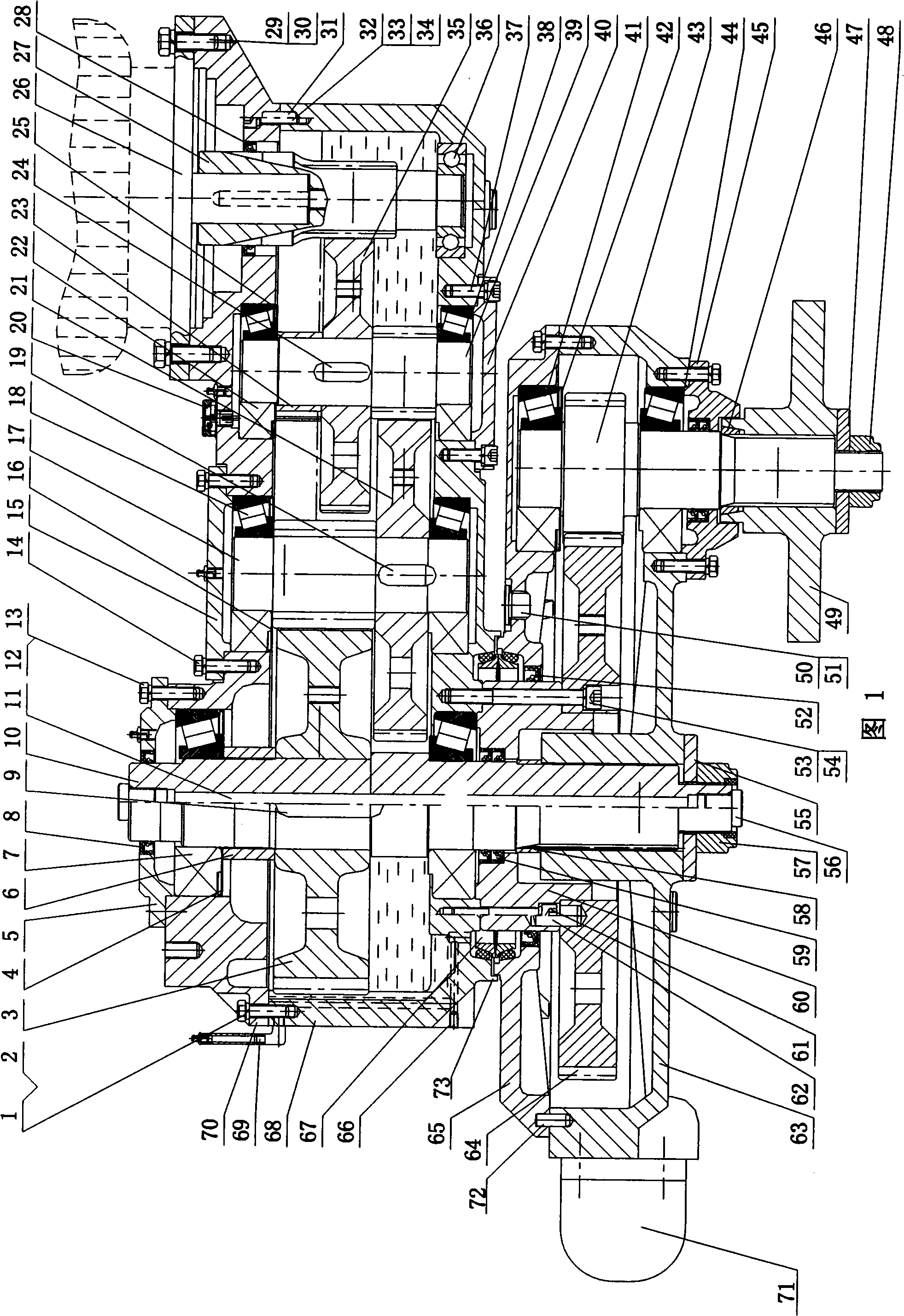

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0017] Please refer to Fig. 1, on the upper case body 68 that oiler 69 is housed, by screw 1,32,33,34 and elastic washer 2, pin 31, upper case cover 70 is installed, has on the upper case cover and shows oil vent cap 20 , The side of the lower end of the upper casing is shaped on an oil circuit process hole, and a screw plug 66 is installed on the hole port. A hollow input gear shaft 27 is installed in the upper case through a bearing 36 and a skeleton oil seal 28 . The motor 26 that drives the hollow input gear shaft is installed by screw 29 and spring washer 30 on the upper case cover. In the upper box, the input gear shaft 39 and the input gear 35 meshing with the hollow input gear shaft are installed through the bearing 38, 22, the washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com