Envelope type reactor thermal-transferring method in methanol synthesizing process

A shell-and-tube reactor and methanol synthesis technology, which is applied to chemical instruments and methods, preparation of organic compounds, lighting and heating equipment, etc., can solve the problems of not being able to move out of the methanol synthesis tower in a sufficient and timely manner, so as to increase water volume and meet Effect of high load requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

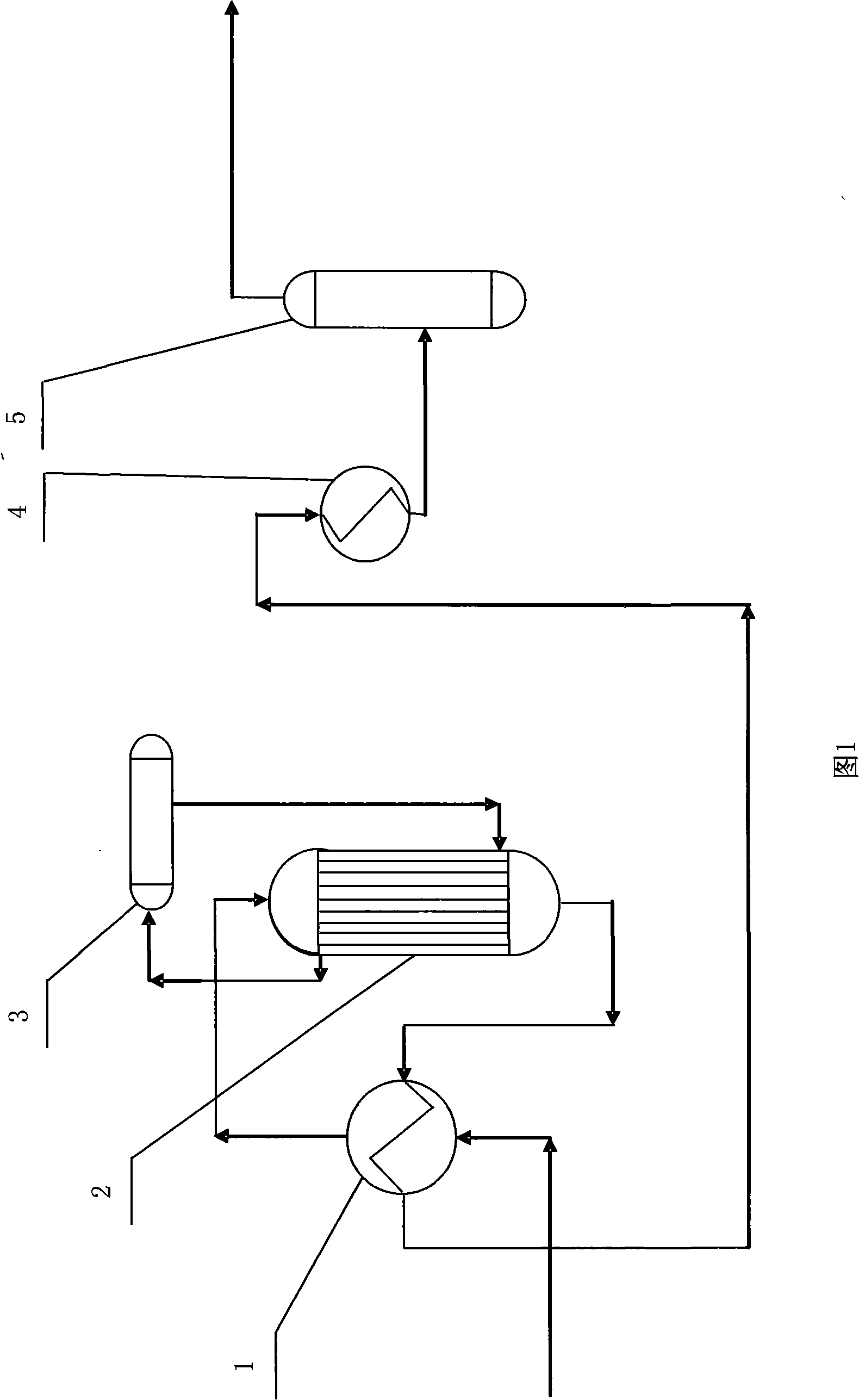

Embodiment approach 1

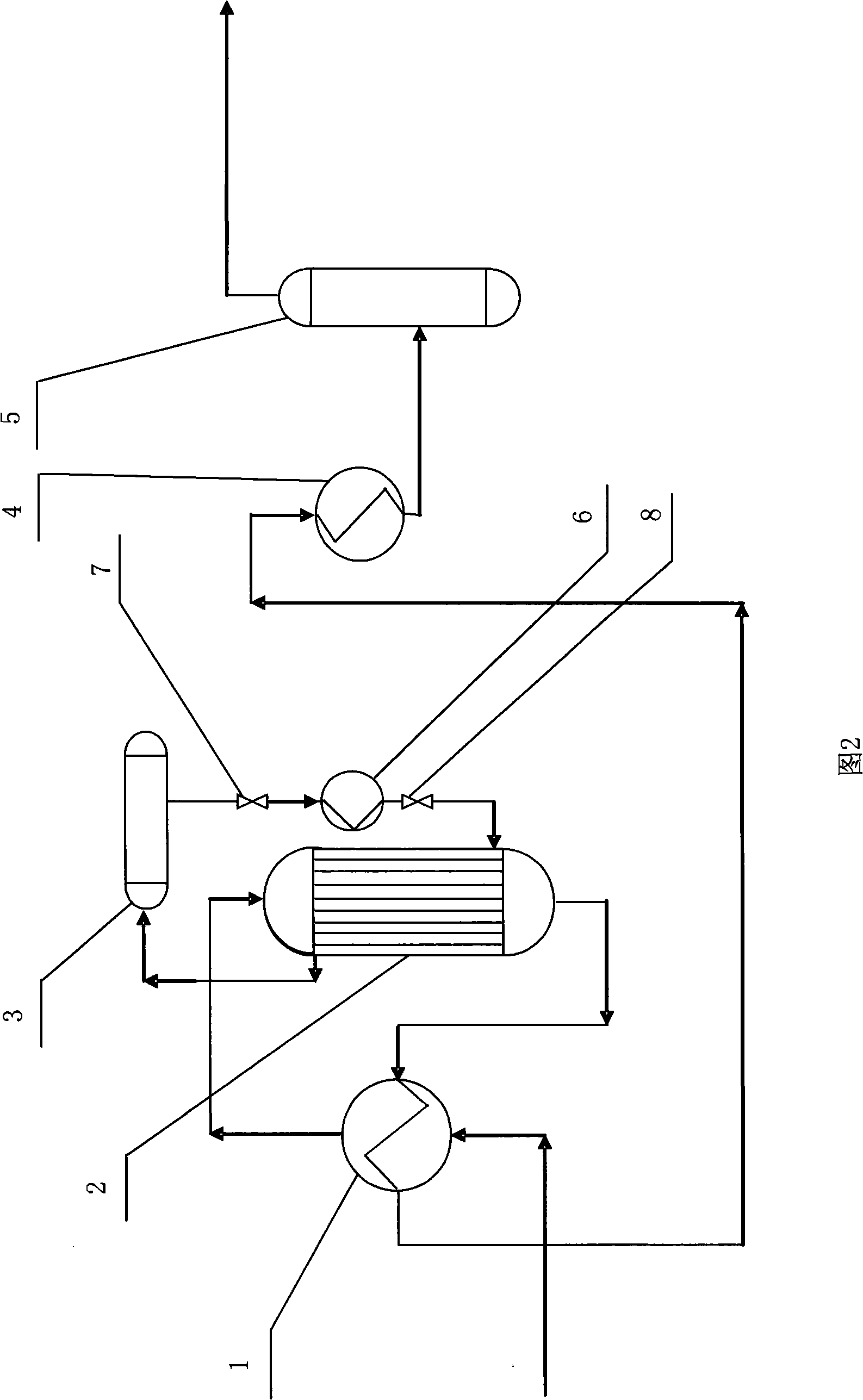

[0016] As shown in Figure 2: the shell-and-tube reactor heat transfer method of the methanol synthesis process of the present invention adopts the shell-and-tube methanol synthesis reactor, and the methanol synthesis reaction uses the gas containing carbon monoxide, carbon dioxide and hydrogen as raw materials, which enters after compression The shell side of the intermediate heat exchanger (1), after being heated to the reaction temperature, enters the tube side of the methanol synthesis tower (2), and under the action of a catalyst, the synthesis reaction gas undergoes methanol synthesis reaction; part of the synthesis reaction gas temperature rises , the gas out of the synthesis tower enters the tube side of the intermediate heat exchanger (1), and after being cooled, it enters the methanol condenser (4), and after the methanol is condensed, it enters the methanol separator (5). After the methanol is separated, the unreacted The gas returns to the inlet of the circulating co...

Embodiment approach 2

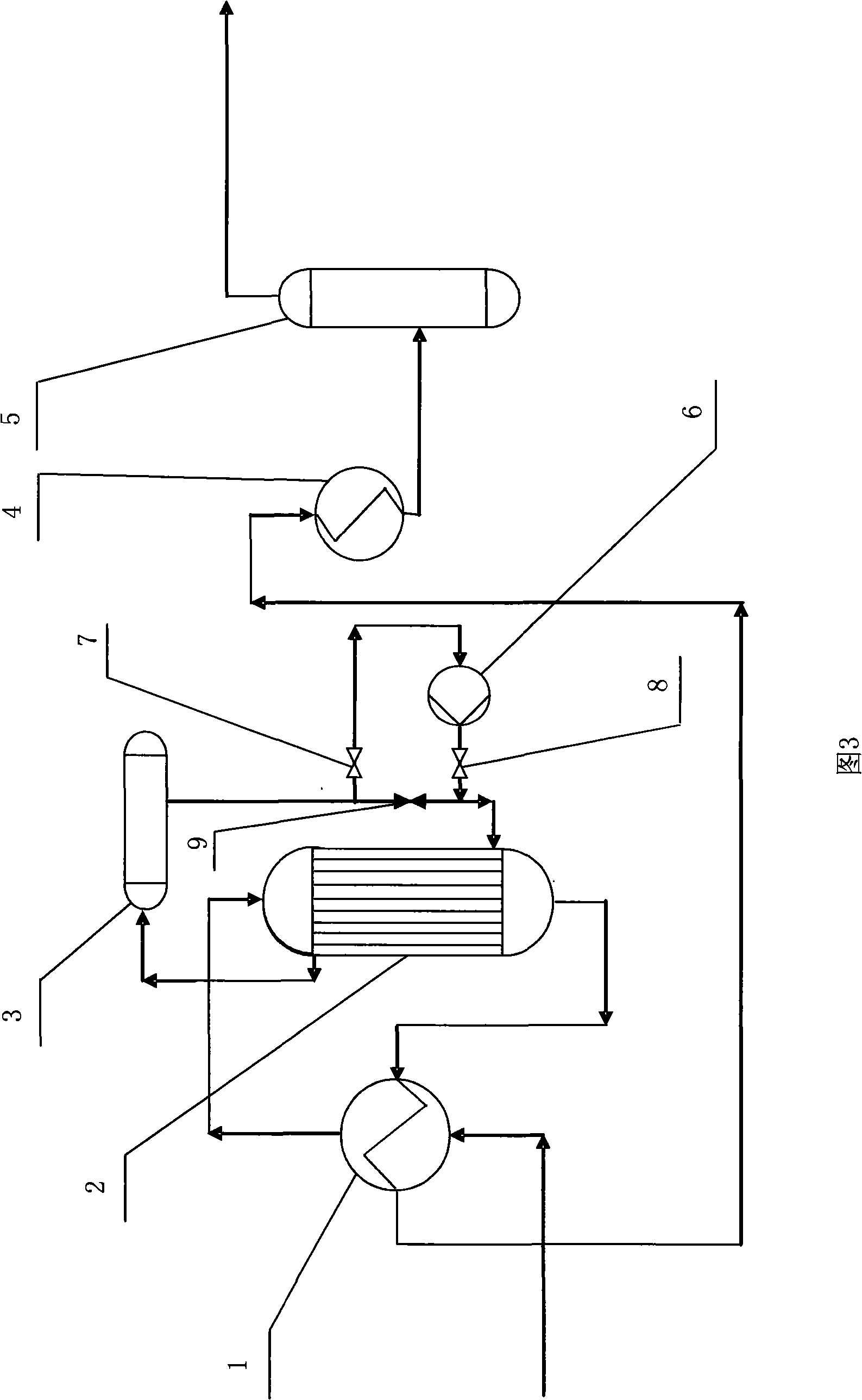

[0020] As shown in Figure 3: the shell-and-tube reactor heat removal method of methanol synthesis process of the present invention, it also can adopt another kind of water supply circulation system, valve (9) is installed on the downcomer of former steam drum, and valve also can be automatic valve , the valve (9) pipeline on the downcomer is connected in parallel with the water pump (6) pipeline, that is, the two ends of the valve (9) are respectively connected to the circulating water pump (6) through the input pipeline and output pipeline of the water pump (6), An input valve (7) and an output valve (8) are respectively installed on the input pipeline and the output pipeline; the water pump (6) can also be designed as two sets, and when the water pump (6) has an empty pump failure, the other water pump can automatically Work, guarantee that the water supply circulation system is normal; Water pump (6) also can be designed to automatic control, break down when water pump works...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com