Electric energy optimizing process in zinc electrolyzing process

An optimization method, zinc electrolysis technology, applied in photography technology, equipment, photography auxiliary technology, etc., can solve the problem of high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

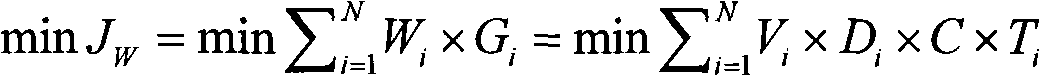

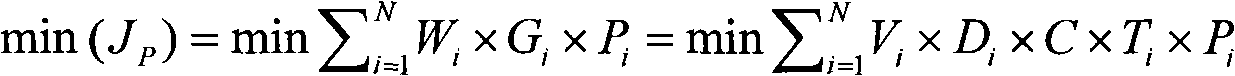

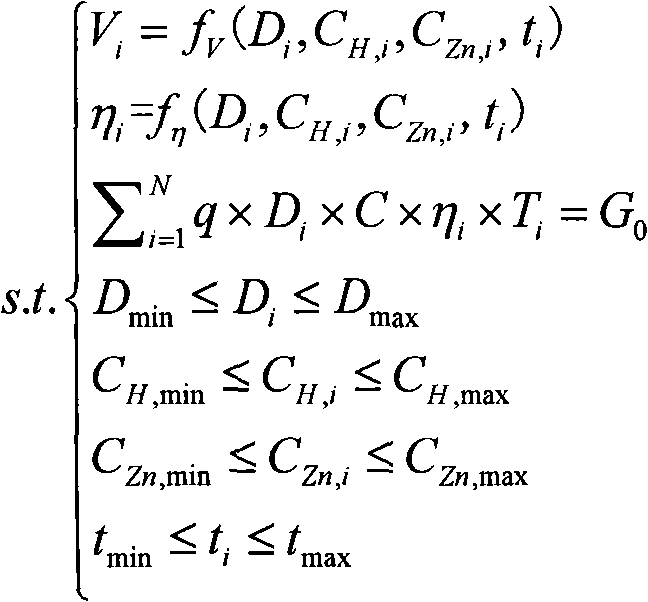

Method used

Image

Examples

Embodiment Construction

[0076] The process parameters of 7 series of zinc electrolysis plants in a smelting group are: the number of time-sharing billing periods N=4, the duration of each period of hours (T 1 ,T 2 ,T 3 ,T 4 ) = (5, 4, 7, 8), the electricity price of each period (P 1 , P 2 , P 3 , P 4 )=0.392×(1 / 9, 1.35, 1.0, 0.4) Yuan / (kW·h), the number of series m=7, the number of electrolyzers of each series (n 1 , n 2 , n 3 , n 4 , n 5 , n 6 , n 7 )=(240, 240, 246, 192, 208, 208, 208), the number of boards in each slot (b 1 , b 2 , b 3 , b 4 , b 5 , b 6 , b 7 )=(34, 46, 54, 56, 56, 57, 57), cathode plate area S 0 =1.13m 2 , planned output G 0 =960t.

[0077] On the basis of fully studying the actual production situation of the enterprise and ensuring the production conditions corresponding to the actual production process, through the zinc electrolysis condition test in the laboratory, the cell voltage, current efficiency, power consumption and current density, electrolyte T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com