Elastic sleeper type ballastless bed

A sleeper and elastic technology, applied in the field of railway track structure, can solve the problems of reducing the comfort of train operation, inconvenient equipment and tools, and hidden dangers of driving safety, so as to achieve good vibration isolation effect and stability, reduce maintenance workload, and ensure Smooth and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

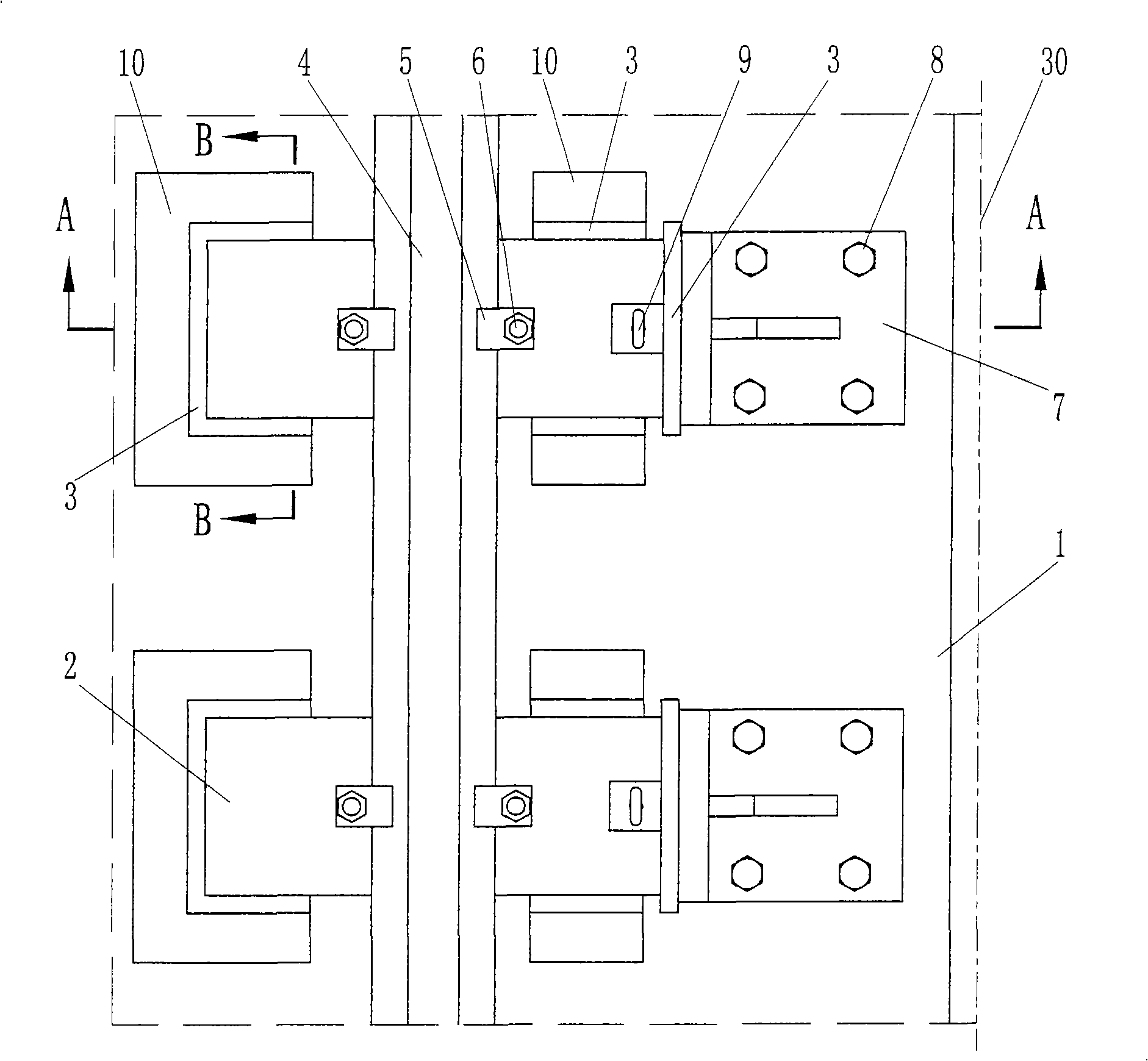

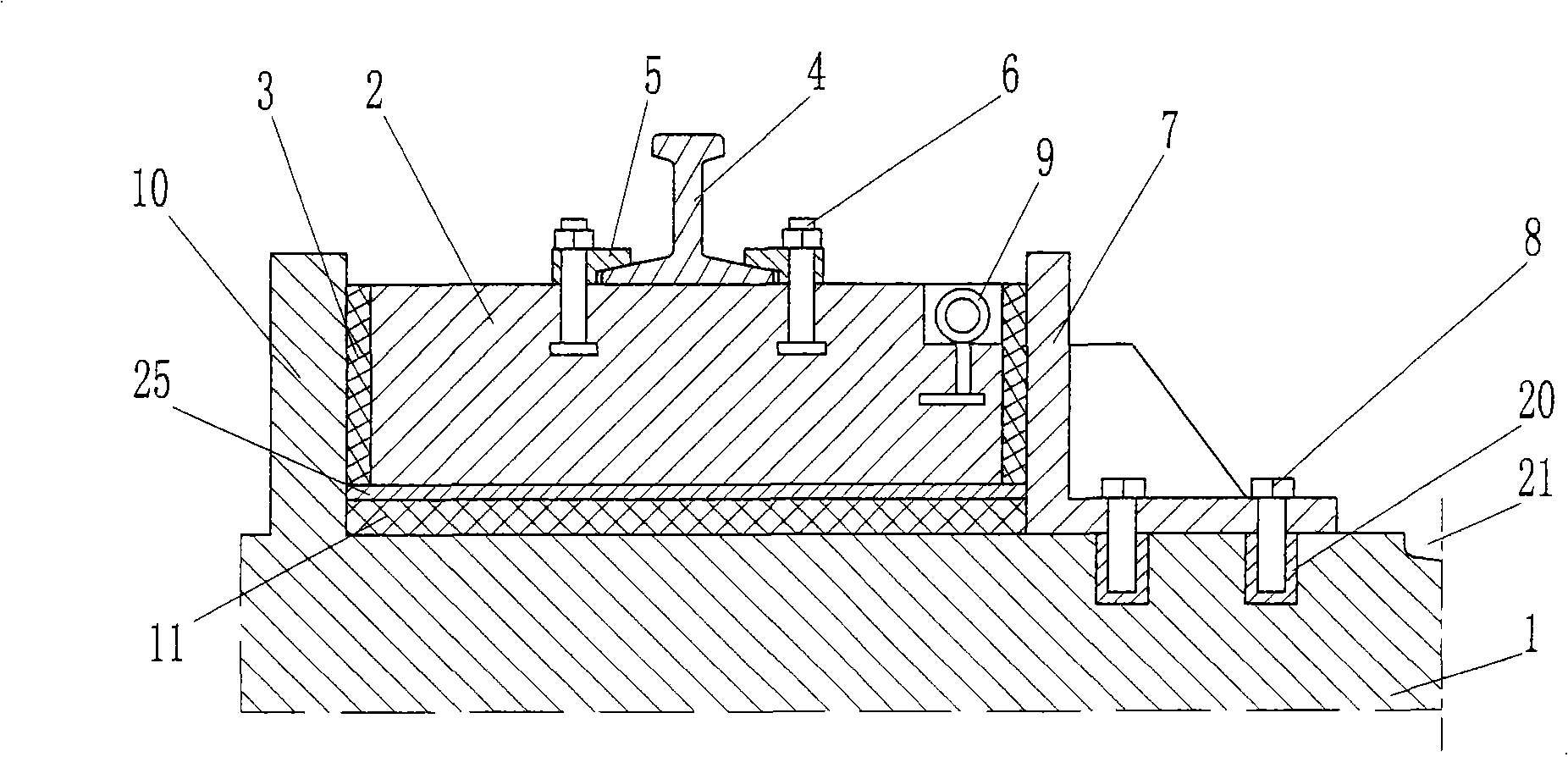

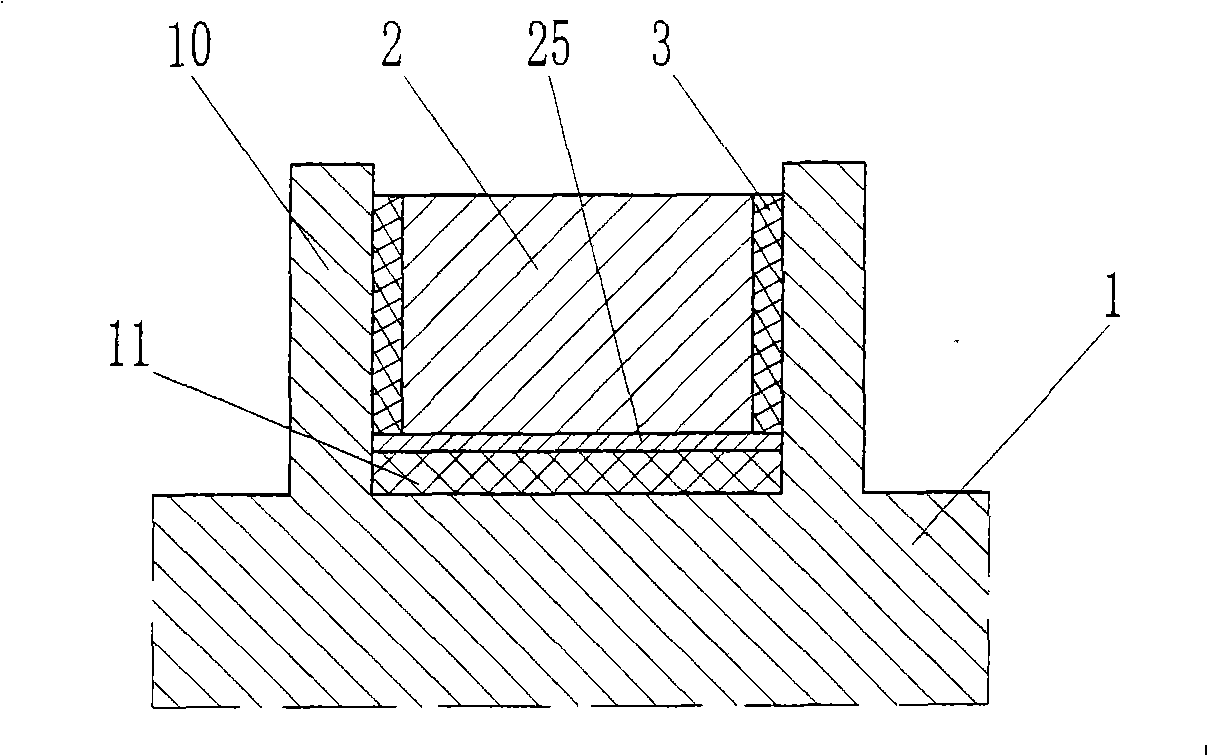

[0030] Such as figure 1 , figure 2 , image 3The shown elastic sleeper ballastless ballast bed of the present invention includes a ballast bed body 1, a sleeper 2 and a rail 4, wherein the sleeper 2 is a short sleeper, the sleeper 2 is placed on the ballast bed body 1, and the rail 4 is fixed by fasteners 5 and bolts 6. Set on sleeper 2. The rubber pad 11 is set below the sleeper 2 as an elastic supporting element, and a height-adjusting gasket 25 made of engineering plastics is also provided as a height-adjusting device, and the height-adjusting gasket 25 is placed on the rubber pad 11 top. The side of the sleeper 2 is also provided with a guide device, including a fixed stopper 10 integrated on the ballast bed body 1 and a detachable movable stopper 7, and the movable stopper 7 is fixedly arranged on the ballast bed through the fastening bolt 8 and the connecting sleeve 20. On the main body, the sleeper 2 is defined in the groove that is surrounded by the fixed block 10 ...

Embodiment 2

[0034] Such as Figure 4 As shown, compared with Embodiment 1, in order to prevent the rubber elastic guide backing plate 3 from being directly set between the fixed block 10 and the sleeper 2, the rubber elastic guide backing plate 3 and the stopper are not easy to stick firmly, which may occur after disengagement. To move, a connecting plate 13 can be set, the rubber elastic guide backing plate 3 and the connecting plate 13 are vulcanized into one, and then the fastener 14 is used to fix it on the fixed block. In the same way, it is also possible to arrange a coupling plate on the movable stopper 7 (not shown in the figure, generally using metal material) or directly vulcanize the rubber elastic guide backing plate 3 and the movable stopper 7 into one. In addition, since the rubber pad 11 as an elastic supporting element is prone to fatigue and aging, it can be vulcanized and used in parallel with the disc spring 12 to improve the service life of the elastic supporting eleme...

Embodiment 3

[0037] Such as Figure 5 , Figure 6 The difference between the elastic sleeper type ballastless ballast bed of the present invention compared with the first embodiment is that the fixed block 10 is formed by the side wall of the groove arranged on the ballast bed body, and the groove is opened and set on the outer side of the ballast bed body 1 , Utilize fixed bolt 8 to be fixedly arranged on movable block 7 on the ballast bed body 1 of this side, the outer space of movable block can be used as maintenance replacement space. In order to facilitate the positioning and loading and unloading of the sleeper 2, the contour shape surrounded by the groove and the movable stopper 7 is set as a trapezoid, and the corresponding sleeper 2 is also set as a trapezoid. The advantage of using a trapezoidal sleeper is that when the sleeper is taken out, once the sleeper side is When the metal elastic piece is loosened, the friction force on both sides disappears, and it is easy to take out....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com